Superfine-fiber-shaped polymer immobilized catalyst, and preparation method and application thereof

A technology of ultra-fine fibers and polymers, applied in chemical instruments and methods, preparation of organic compounds, physical/chemical process catalysts, etc., can solve the problems of high corrosion of equipment and difficult recovery of catalysts, and achieve simple recovery and improved processing Applicability and durability, and the effect of improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

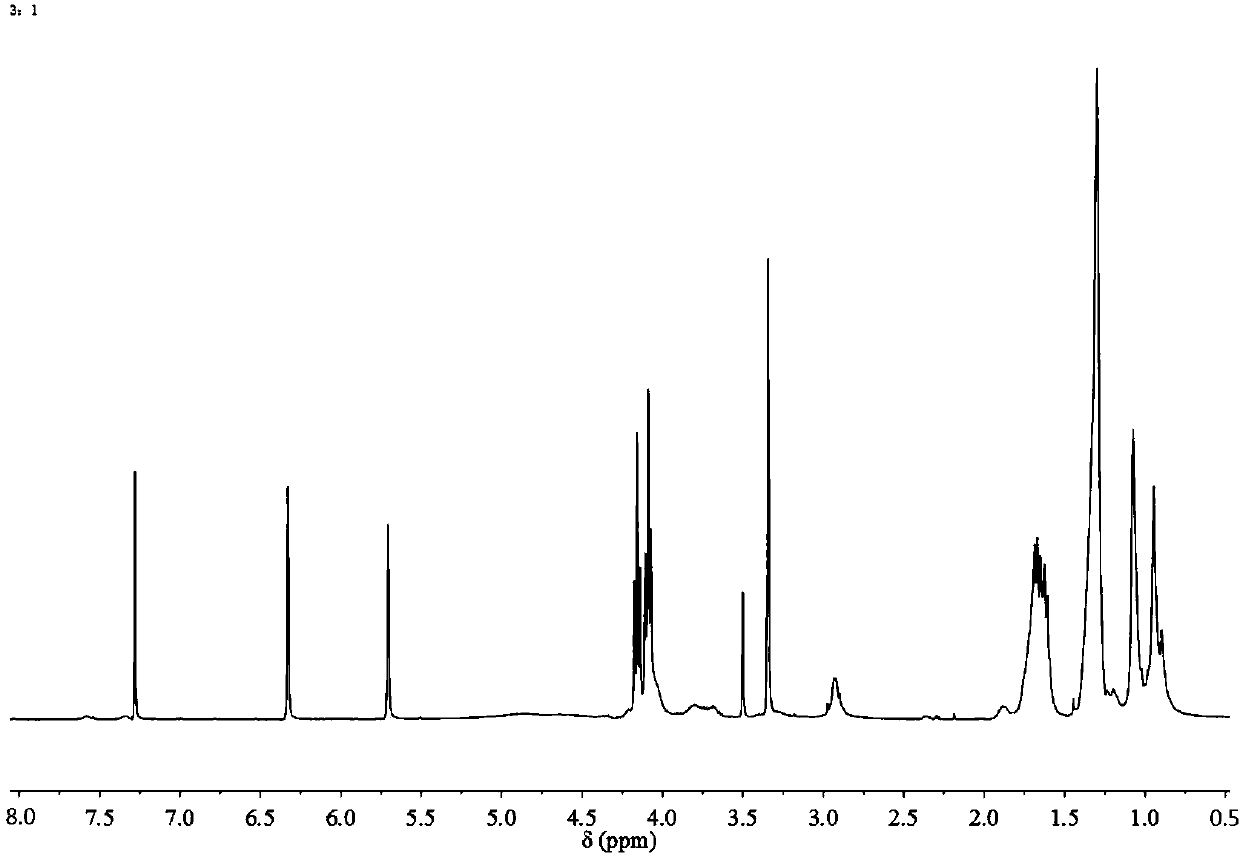

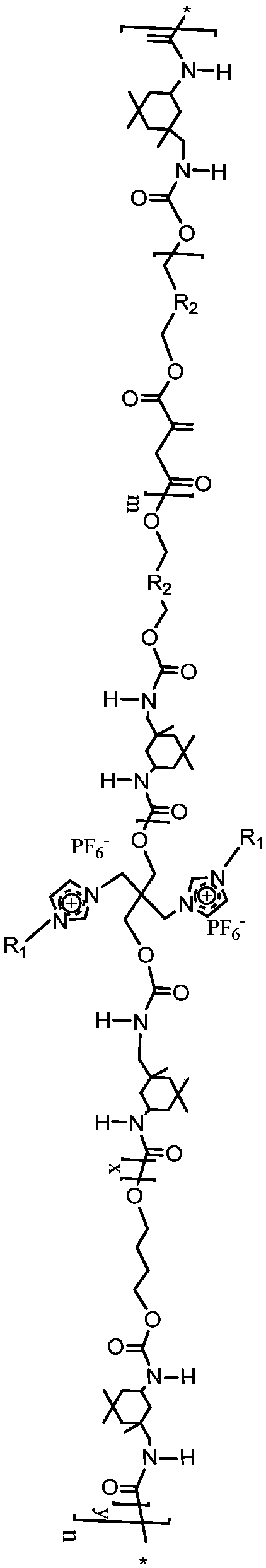

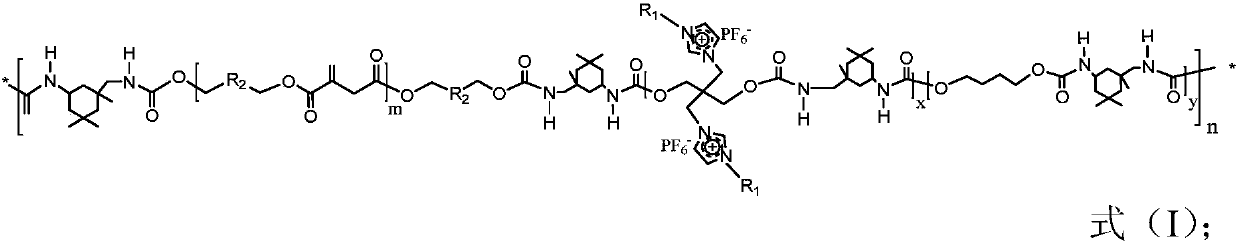

Image

Examples

Embodiment 1

[0061] After weighing 15 g of dibromoneopentyl glycol and 18.5 g of 1-butylimidazole respectively, add them into a reaction kettle equipped with magnetic stirring, a thermometer, and a condenser. The temperature was raised to 150°C to initiate the reaction. After 5 hours of reaction, the reaction was stopped, the temperature was lowered to room temperature, washed and filtered, and dried at 80°C for 12 hours to obtain dibutylimidazole neopentyl glycol bromide.

[0062] Weigh 10 g of dibutylimidazole neopentyl glycol bromide and 8.11 g of ammonium hexafluorophosphate, dissolve them in 20 ml of deionized water, and put them into a reaction kettle with magnetic stirring. After reacting at room temperature for 5 hours, washing and filtering, and vacuum drying at 80°C for 10 hours, dibutylimidazole neopentyl glycol hexafluorophosphate was obtained.

[0063] Weigh 4 g of itaconic acid-based polyester, 1.7878 g of dibutylimidazole neopentyl glycol hexafluorophosphate, 0.5028 g of 1,4...

Embodiment 2

[0073] After weighing 15 g of dibromoneopentyl glycol and 20 g of 1-methylimidazole respectively, add them into a reaction kettle equipped with magnetic stirring, a thermometer, and a condenser. The temperature was raised to 120°C to initiate the reaction. After 8 hours of reaction, the reaction was stopped, the temperature was lowered to room temperature, washed and filtered, and dried at 80°C for 10 hours to obtain dibutylimidazole neopentyl glycol bromide.

[0074] Weigh 10 g of dimethylimidazolium neopentyl glycol bromide and 12 g of ammonium hexafluorophosphate, dissolve them in 10 ml of deionized water, and put them into a reaction kettle with magnetic stirring. After reacting at room temperature for 6 hours, washing and filtering, and vacuum drying at 80° C. for 5 hours, dibutylimidazole neopentyl glycol hexafluorophosphate was obtained.

[0075] Weighed 7.5 g of itaconic acid-based polyester, 2.7648 g of dimethylimidazolium neopentyl glycol hexafluorophosphate, 0.8950 ...

Embodiment 3

[0084] After weighing 20 g of dibromoneopentyl glycol and 35 g of 1-methylimidazole respectively, add them into a reaction kettle equipped with magnetic stirring, a thermometer, and a condenser. The temperature was raised to 140°C to initiate the reaction, and after 7 hours of reaction, the reaction was stopped, the temperature was lowered to room temperature, washed and filtered, and dried at 80°C to obtain dibutylimidazole neopentyl glycol bromide.

[0085] Weigh 10 g of dimethylimidazolium neopentyl glycol bromide and 16 g of ammonium hexafluorophosphate, and put them into a reaction kettle with magnetic stirring. After reacting at room temperature for 6 hours, washing and filtering, and vacuum drying at 80°C, dibutylimidazole neopentyl glycol hexafluorophosphate was obtained.

[0086] Weigh 6 g of itaconic acid-based polyester, 5.0564 g of dimethylimidazolium neopentyl glycol hexafluorophosphate, 0.3600 g of 1,4-butanediol, and 4.3958 g of isophorone diisocyanate. First, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com