Titanium dioxide/sulfonated oxidized graphene/silver nanoparticle composite film and preparation method and application thereof

A technology of silver nanoparticles and titanium dioxide, applied in the direction of titanium oxide/hydroxide, titanium dioxide, chemical instruments and methods, etc., can solve the problems of rare materials and achieve low cost, superior oil/water separation performance, and easy to obtain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation of sulfonated graphene oxide, the specific steps are as follows:

[0044] Mix 180ml of concentrated sulfuric acid and 20ml of concentrated phosphoric acid (180:20) evenly, accurately weigh 1.5g of graphite flakes, and mix and stir for 15 minutes. Weigh 9g of potassium permanganate again, and add it slowly while stirring. It was then stirred for 12 hours in an oil bath at 50°C. After cooling to room temperature, pour it into 200 ml of ice water, add an appropriate amount of hydrogen peroxide until the solution turns yellow, wash with 5% hydrochloric acid solution for 3 times after centrifugation, and then wash with deionized water several times until the pH is 5 to 6. Dialyze for another week, change the water frequently every day, and finally put it into a watch glass and freeze it at -40 degrees Celsius, and then vacuum dry it until it becomes fluffy.

[0045]Mix 200mg of graphene oxide, 3g of sodium chloroethylsulfonate, and 1.6g of s...

Embodiment 2

[0046] Embodiment two: the preparation of silver nanoparticles and sulfonated graphene oxide composite material, concrete steps are as follows:

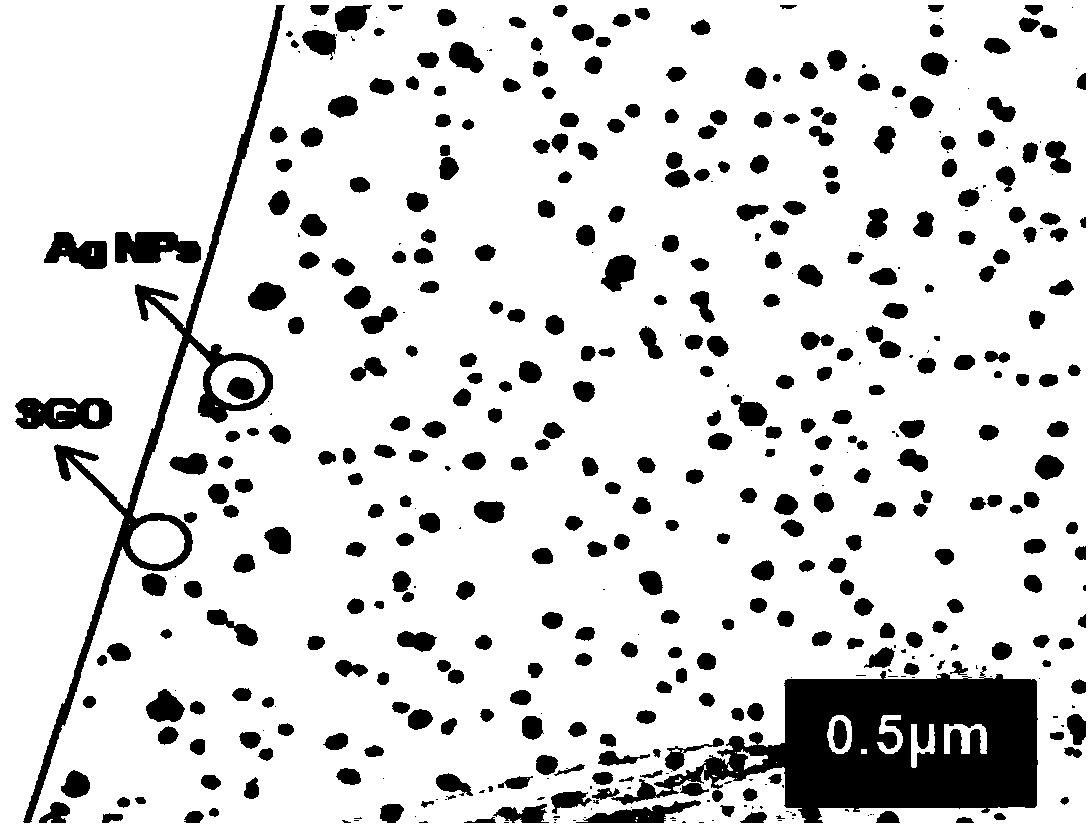

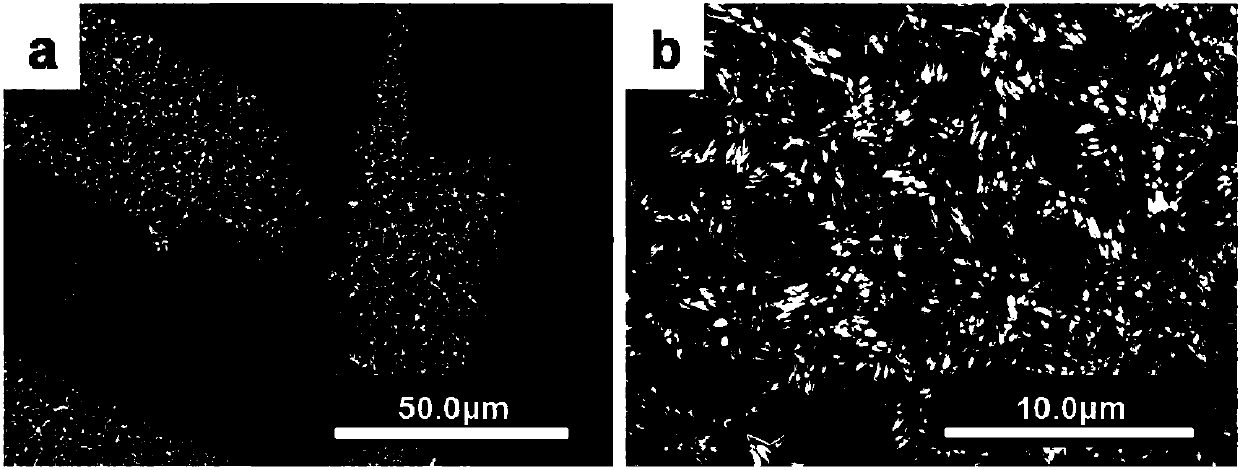

[0047] Add 4 ml of silver nitrate aqueous solution (0.2 M) into a beaker containing 20 ml of sulfonated graphene oxide dispersion (1 mg / ml), and stir magnetically for 3 hours (25 degrees Celsius). Then 2 ml of ascorbic acid (0.5M) was quickly added to the mixture, and magnetic stirring was continued for 1 hour. The reactants were centrifuged and washed with ultrapure water for several times. The final product silver nanoparticles / sulfonated graphene oxide composite was dispersed in 20 ml of in ultrapure water; figure 1 It is a scanning electron microscope image of silver nanoparticles and sulfonated graphene oxide composite material, and the distribution of nanoparticles can be seen through the picture.

Embodiment 3

[0048] Embodiment three: the preparation of titanium dioxide nanorod array, concrete steps are as follows:

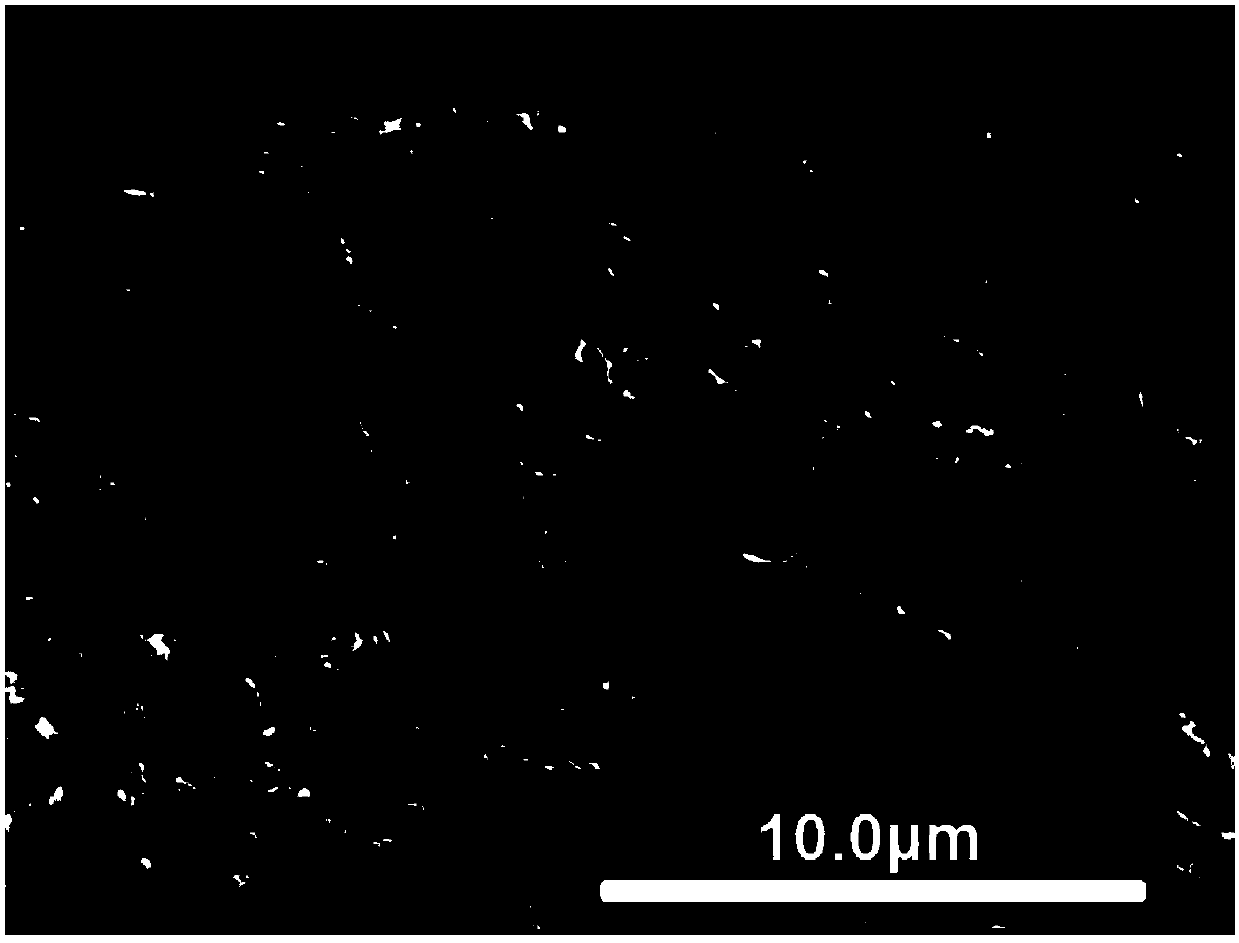

[0049] The cleaned copper mesh was placed in a reaction kettle, and 2.5 ml of tetra-n-butyl titanate, 12.5 ml of glycerin, and 37.5 ml of ethanol were added, mixed evenly, and reacted at 180 degrees Celsius for 24 hours to obtain a metal mesh with titanium dioxide nanoclusters; then The titanium dioxide nanocluster network was ultrasonically cleaned with sulfuric acid (0.5M) and acetone, respectively, and then subjected to hydrothermal treatment; 4.05 ml of titanium trichloride, 31 ml of supersaturated sodium chloride solution and 0.3 g of urea, the mixed solution was placed Put the cleaned net against the wall of the kettle, react at 160 degrees Celsius for 2 hours, then take out the sample and immerse it in sulfuric acid for 5 minutes, then wash it with distilled water and ethanol for 3 times, and dry the sample in vacuum at 60 degrees Celsius for 10 hours ; attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com