Treatment method for sulfur-containing industrial waste gases

A treatment method and technology for industrial waste gas, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of waste of sulfur-containing gas, environmental pollution, etc., achieve enhanced adsorption capacity, reduce water vapor content, and improve adsorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

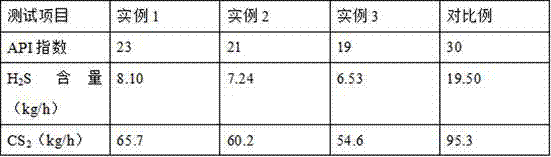

Examples

example 1

[0023] Weigh 0.5 kg of activated carbon and place it in a mortar for grinding for 16 minutes to pass through an 80-mesh sieve to collect the sieved activated carbon powder. Soak in a beaker of nickel nitrate solution for 1h to obtain the soaked sieved activated carbon powder, then rinse the soaked sieved activated carbon powder with deionized water, and adjust the pH to 6, remove the carbon powder and impurities adhering to the carbon particles, and obtain For the washed activated carbon, continue to place the washed activated carbon in a muffle furnace at 500°C for 1 hour, discharge the material to obtain modified activated carbon, mix potassium dihydrogen phosphate, sodium nitrate, and sucrose in an equal mass ratio to obtain a mixture, and then mix the mixture Mix with water at a mass ratio of 1:3, stir at a temperature of 20°C for 12 minutes to obtain a self-made mixture, and weigh 30 parts of self-made activated carbon and 16 parts of self-made mixture in parts by weight a...

example 2

[0025] Weigh 0.6 kg of activated carbon and place it in a mortar for grinding for 18 minutes to pass through a 90-mesh sieve, collect the sieved activated carbon powder, put the sieved activated carbon powder into 40 mL of nitric acid solution with a mass fraction of 3% and 25 mL of 35% nitric acid with a mass fraction of Soak in a beaker of nickel nitrate solution for 1.5h to obtain the soaked sieved activated carbon powder, then rinse the soaked sieved activated carbon powder with deionized water, and adjust the pH to 7 to remove the carbon powder and impurities adhering to the carbon particles. To obtain the water-washed activated carbon, continue to place the water-washed activated carbon in a muffle furnace at 600° C. for roasting for 1.5 h, discharge the material to obtain a modified activated carbon, mix potassium dihydrogen phosphate, sodium nitrate, and sucrose in an equal mass ratio to obtain a mixture, and then Mix the mixture and water at a mass ratio of 1:3, and st...

example 3

[0027] Weigh 0.7kg of activated carbon and put it in a mortar and grind for 20min to pass through a 100-mesh sieve, collect the sieved activated carbon powder, put the sieved activated carbon powder into 3% nitric acid solution with 50mL mass fraction and 30mL mass fraction of 35% Soak in a beaker of nickel nitrate solution for 2h to obtain the soaked sieved activated carbon powder, then rinse the soaked sieved activated carbon powder with deionized water, and adjust the pH to 8, remove the carbon powder and impurities adhering to the carbon particles, and obtain For the washed activated carbon, continue to place the washed activated carbon in a muffle furnace at 700°C for 2 hours and discharge the material to obtain modified activated carbon. Mix potassium dihydrogen phosphate, sodium nitrate, and sucrose in an equal mass ratio to obtain a mixture, and then mix the mixture Mix with water at a mass ratio of 1:3, stir at a temperature of 30°C for 16 minutes to obtain a self-made...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com