Insulation flame-retardant and fireproof power cable for nuclear power plant and fabrication method of power cable

A technology for power cables and nuclear power plants, which is applied in the field of insulating, flame-retardant and fire-resistant power cables for nuclear power plants and their preparation, can solve the problem that the γ-ray resistance and mechanical properties need to be improved, and the normal operation of the cables cannot be effectively guaranteed, and the high temperature resistance and fire resistance limit are low. and other problems to achieve the effect of reducing noise pollution, preventing internal fire, and improving fire protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

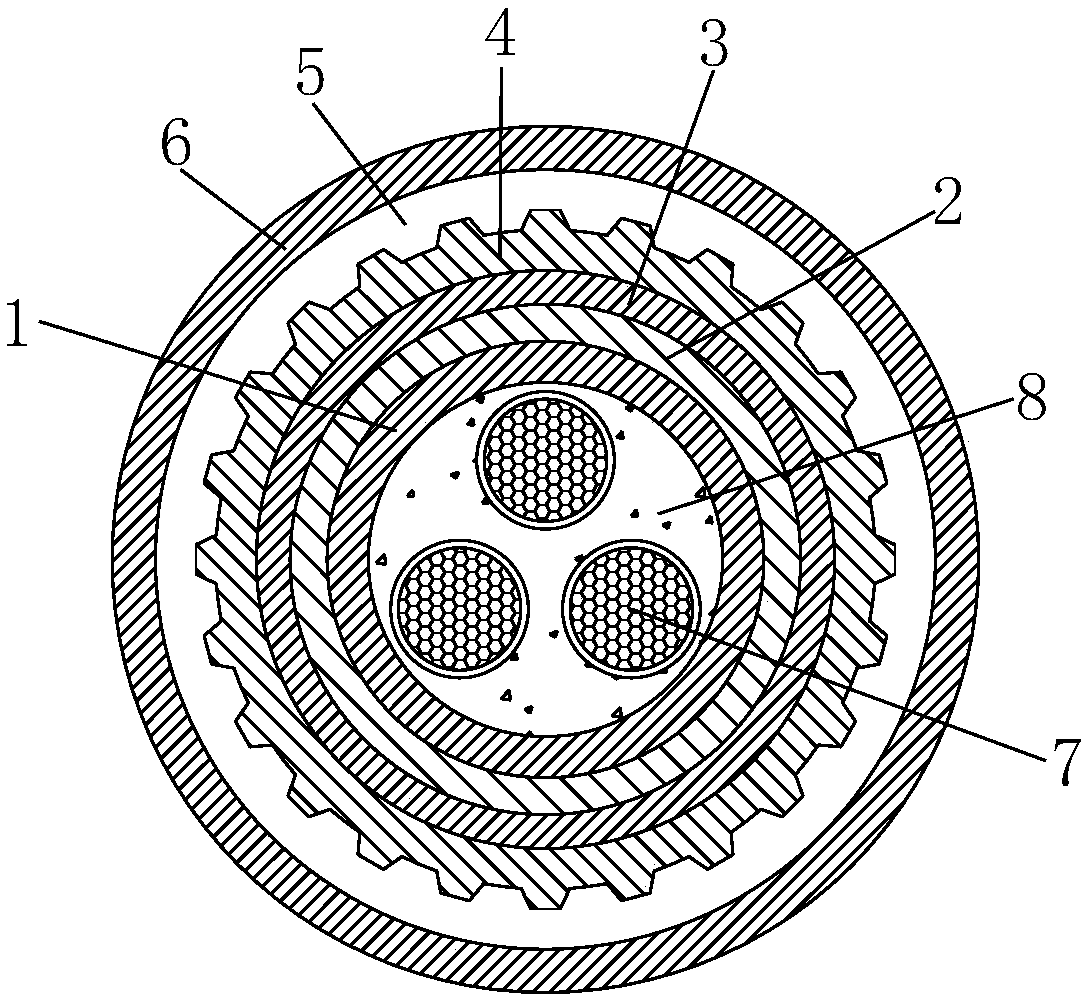

[0026] The preparation method of the insulating, flame-retardant and fire-resistant power cable for nuclear power plants of the present invention comprises the following steps:

[0027] a. Draw and anneal the round metal wire to make a conductor, dip the conductor in insulating varnish, and then extrude the insulation layer outside the conductor to form the insulated core 7. After the multiple insulated cores 7 are twisted together, A layer of rock wool fiber 8 is coated on the outside to form a cable core.

[0028]b. Wrap the shielding layer 1 outside the cable core, then wrap the polyester tape around the shielding layer 1 to form a polyester tape reinforcement layer 2, and then wrap the mica tape around the polyester tape reinforcement layer 2 to form a fire-resistant mica tape Layer 3.

[0029] c. Preparation of the inner sheath layer 4: first prepare the raw materials according to the weight, and pass the phenolic resin through a crusher to make phenolic resin particles ...

Embodiment 1

[0033] Insulated flame-retardant and fire-resistant power cables for nuclear power plants prepared by the above method, the radiation-resistant layer 6 is made of the following raw materials in parts by weight: 80 parts of polyvinyl chloride, 90 parts of polypropylene, 20 parts of polycarbonate, and 40 parts of phenolic resin , 40 parts of epoxy resin, 20 parts of polydimethylsiloxane, 10 parts of polyvinylpyrrolidone, 5 parts of decabromodiphenylethane, 5 parts of decabromodiphenyl ether, 18 parts of stearic acid, hydroxyethyl cellulose 8 parts of plain fiber, 8 parts of long glass fiber, 5 parts of aluminum tripolyphosphate, 4 parts of silicon nitride, 4 parts of borax, 5 parts of sodium succinate, and 3 parts of silica gel.

[0034] The inner sheath layer 4 is made of the following raw materials in parts by weight: 40 parts of phenolic resin, 20 parts of magnesium hydroxide, 30 parts of polypropylene, 2 parts of melamine cyanurate, 5 parts of fumed silica, Ca / Zn 5 parts of ...

Embodiment 2

[0036] Insulated flame-retardant and fire-resistant power cables for nuclear power plants prepared according to the above method, the radiation-resistant layer 6 is made of the following raw materials in parts by weight: 95 parts of polyvinyl chloride, 95 parts of polypropylene, 25 parts of polycarbonate, and 45 parts of phenolic resin , 45 parts of epoxy resin, 23 parts of polydimethylsiloxane, 15 parts of polyvinylpyrrolidone, 8 parts of decabromodiphenylethane, 8 parts of decabromodiphenyl ether, 20 parts of stearic acid, hydroxyethyl cellulose 9 parts of plain fiber, 10 parts of long glass fiber, 6 parts of aluminum tripolyphosphate, 5 parts of silicon nitride, 5 parts of borax, 5 parts of sodium succinate, and 3 parts of silica gel.

[0037] The inner sheath layer 4 is made of the following raw materials in parts by weight: 50 parts of phenolic resin, 30 parts of magnesium hydroxide, 45 parts of polypropylene, 4 parts of melamine cyanurate, 7 parts of fumed silica, Ca / Zn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com