A kind of elastic permeable brick

A permeable brick, elastic technology, applied in the direction of roads, ceramic products, applications, etc., can solve the problems of low compressive strength of the brick body, affecting the overall strength of the brick body, low production efficiency, etc., to improve durability and enhance bonding. strength, the effect of improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

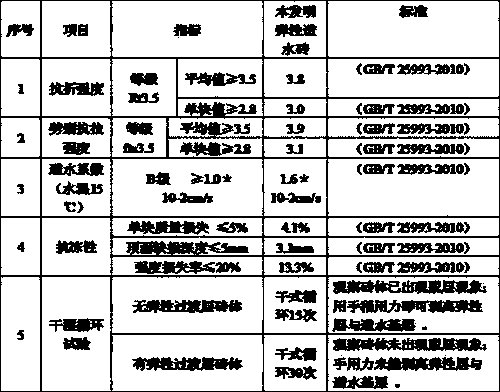

Embodiment 1

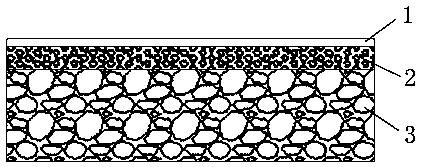

[0047] As a preferred embodiment of the present invention, this embodiment discloses an elastic permeable brick, which includes:

[0048] An elastic permeable brick, comprising a permeable base layer 3, an elastic transition layer 2 and an elastic surface layer 1;

[0049] The water-permeable base layer 3 includes the following components by weight:

[0050] Graded gravel 15kg,

[0051] 3.42kg of Portland cement with a strength of 42.5,

[0052] water 974g,

[0053] Polycarboxylate-based superplasticizer 77.9g;

[0054] The elastic transition layer 2 includes the following components by weight:

[0055] Graded gravel 3kg,

[0056] Rubber granules 1.25kg,

[0057] Bisphenol A epoxy resin 130g,

[0058] T31 curing agent 37.6g,

[0059] Hydrophilic curing agent ED-900 55.1g,

[0060] Coupling agent KH560 0.9g;

[0061] The elastic surface layer (1) includes the following components by weight:

[0062] Rubber pellets 3kg,

[0063] Bisphenol A epoxy resin 72.8g,

[006...

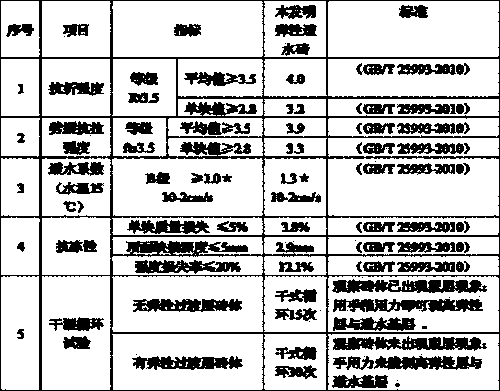

Embodiment 2

[0073] As a preferred embodiment of the present invention, this embodiment discloses an elastic permeable brick, which includes:

[0074] An elastic permeable brick, comprising a permeable base layer 3, an elastic transition layer 2 and an elastic surface layer 1;

[0075] The water-permeable base layer 3 includes the following components by weight:

[0076] Graded gravel 15kg,

[0077] 5.87kg of Portland cement with a strength of 42.5,

[0078] water 1.82kg,

[0079] Polycarboxylate-based superplasticizer 34g;

[0080] The elastic transition layer 2 includes the following components by weight:

[0081] Graded gravel 3kg,

[0082] Rubber granules 1.9kg,

[0083] Bisphenol A epoxy resin 317.5g,

[0084] T31 curing agent 91.6g,

[0085] Hydrophilic curing agent ED-900 134.2g,

[0086] Coupling agent KH560 2.2g;

[0087] The elastic surface layer (1) includes the following components by weight:

[0088] Rubber pellets 3kg,

[0089] Bisphenol A epoxy resin 238.1g,

[...

Embodiment 3

[0099] As a preferred embodiment of the present invention, this embodiment discloses an elastic permeable brick, which includes:

[0100] An elastic permeable brick, comprising a permeable base layer 3, an elastic transition layer 2 and an elastic surface layer 1;

[0101] The water-permeable base layer 3 includes the following components by weight:

[0102] 66 parts of graded gravel,

[0103] 17 parts of inorganic binder,

[0104] 5 parts of water,

[0105] 0.15 parts of water reducing agent;

[0106] The elastic transition layer 2 includes the following components by weight:

[0107] 55 parts of graded gravel,

[0108] 27 parts of rubber particles,

[0109] 5 parts of resin binder;

[0110] The elastic surface layer 1 comprises the following components by weight:

[0111] 88 parts of rubber particles,

[0112] 4 parts of resin binder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com