Method for recovering iron from red mud

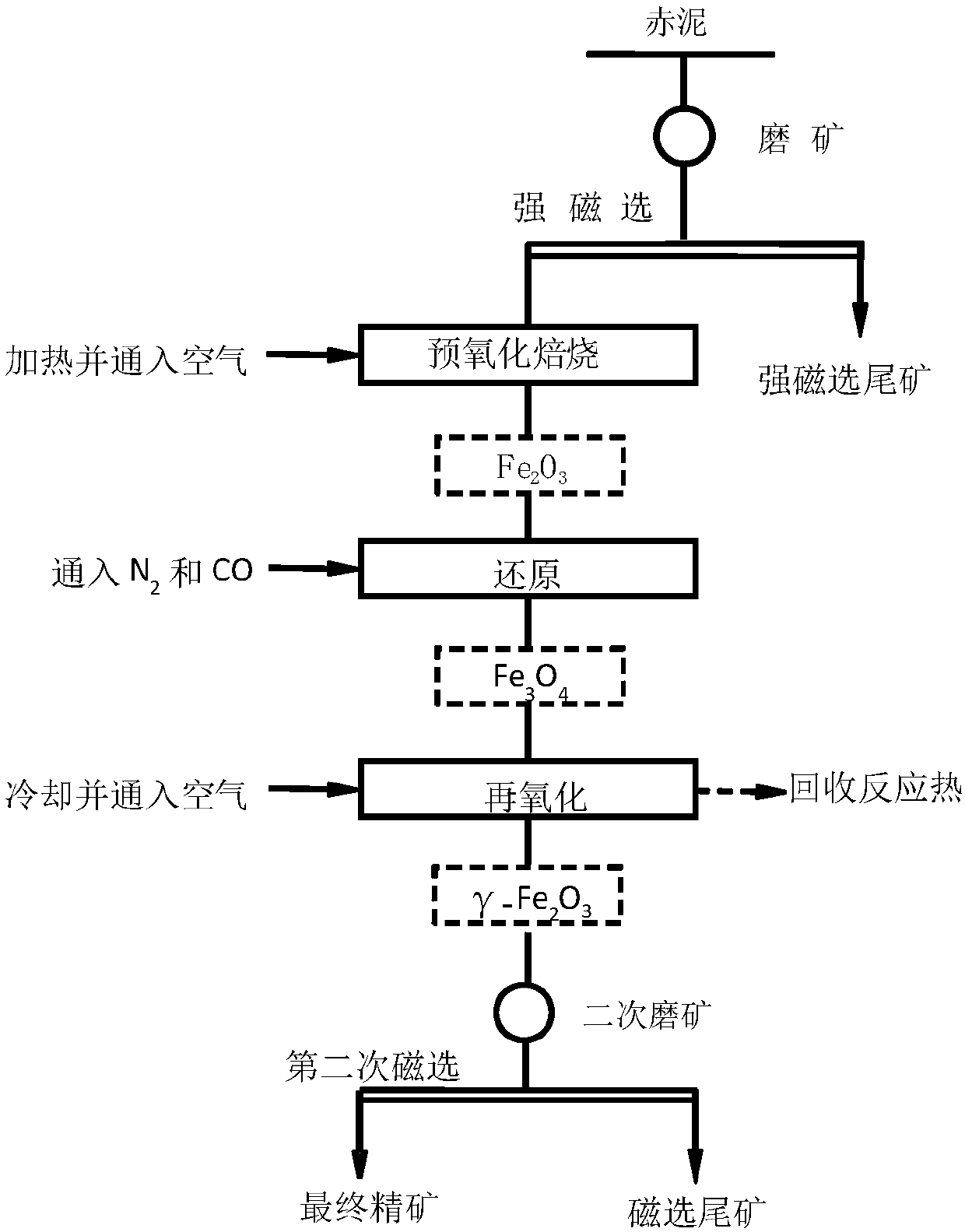

A technology for recovering iron and red mud, which is applied to chemical instruments and methods, magnetic separation, solid separation, etc. It can solve the problems of high energy consumption, inability to guarantee the uniformity of iron mineral reduction, and high CO content in reducing gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The iron grade of the raw red mud used is 34.43%, and the main components after strong magnetic separation are shown in Table 1 (unit wt%);

[0075] Table 1

[0076] components

TF

FeO

SiO 2

Al 2 o 3

CaO

content

44.32

0.66

3.23

13.39

0.93

components

MgO

P

S

K

Na

content

0.19

0.10

0.106

0.063

1.119

[0077] Pre-magnetic separation concentrate chemical phase analysis results are shown in Table 2;

[0078] Table 2

[0079]

[0080] The method proceeds as follows:

[0081] 1. Pre-magnetic separation: Grind the red mud to a particle size of -0.074mm, accounting for 40% of the total weight, and then perform strong magnetic separation with a magnetic field strength of 478kA / m to obtain strong magnetic separation concentrates and strong magnetic separation tailings ; The concentrated ore of strong magnetic separation is a mixed material containing hematite, siderite ...

Embodiment 2

[0089] The iron grade of red mud is TFe 32.47%, containing Al by weight percentage 2 o 3 14.63%, SiO 2 10.53%;

[0090] Method is with embodiment 1, and difference is:

[0091] (1) Grinding the red mud to a particle size of -0.074mm accounts for 50% of the total weight;

[0092] (2) Heat the material in the suspension roasting furnace to 700°C for pre-oxidation roasting, and the pre-oxidation time is 30s;

[0093] (3) The reduction time is 15 seconds; the volume flow ratio of CO and nitrogen is 1:5;

[0094] (4) When the temperature drops to 350°C, air is introduced into the suspension roaster for reoxidation; the main component of the reoxidized material is magnetic iron γ-Fe 2 o 3 and Fe 3 o 4 ; where γ-Fe 2 o 3 The weight content is 60%, Fe 3 o 4 The weight content is 33%, the rest is hematite Fe 2 o 3 ;

[0095] (5) When the part of the material after the secondary grinding to the particle size -0.023mm accounts for 60% of the total weight, the material af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com