A kind of thiopolythiol, preparation method and application in transparent polyurethane material

A polyurethane material and polythiol technology, applied in the preparation of sulfides, organic chemistry, etc., can solve the problems of large dispersion, small refractive index, and unsatisfactory performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of transparent polyurethane material, comprises the steps:

[0051] After mixing thiopolythiol with isocyanate, polyether polyol, chain extender and additives, after mixing evenly, preheat in microwave for 2 minutes, stir mechanically for reaction, and then pour it into the mold after vacuum defoaming. Curing at room temperature gives colorless and transparent polyurethane. The mass percentage of each raw material of the transparent polyurethane material is: thiopolymercaptan 3-6%, isocyanate 40-50%, polyether polyol 30-40%, chain extender 1-10%, auxiliary agent 1-3% . The isocyanate is isophorone diisocyanate (IPDI), hexamethylene diisocyanate (HDI), hydrogenated diphenylmethane diisocyanate (H 12 MDI) one or any combination. The polyether polyol is one or any combination of PPG2000, PPG3000, PEG2000, and PEG300, and the end group of polyethylene glycol can also be modified with active groups to improve the hardness, impact resistance and othe...

Embodiment 1

[0052] Embodiment 1 Preparation of thiopolythiol

[0053] Preparation of Thiopolyols:

[0054] (1) Accurately weigh 10g of NaOH, 2g of triethylbenzyl ammonium chloride (TEBA), dissolve in 40ml of water and transfer to a 250ml three-necked flask; (2) Place the three-necked flask in an ice-water bath until the temperature drops to Below 5°C, add 9.75 g of 2-mercaptoethanol, stir mechanically, control the temperature of the mixed solution in the reactor below 10°C, and add 23 g of epichlorohydrin dropwise. (3) TLC monitors that the raw materials are completely reacted, neutralize the mixed solution with concentrated hydrochloric acid to pH = 5-6, distill under reduced pressure, remove small molecules, remove salt by suction filtration, and obtain 17.2 g of a colorless and odorless transparent liquid. Yield 64.9%.

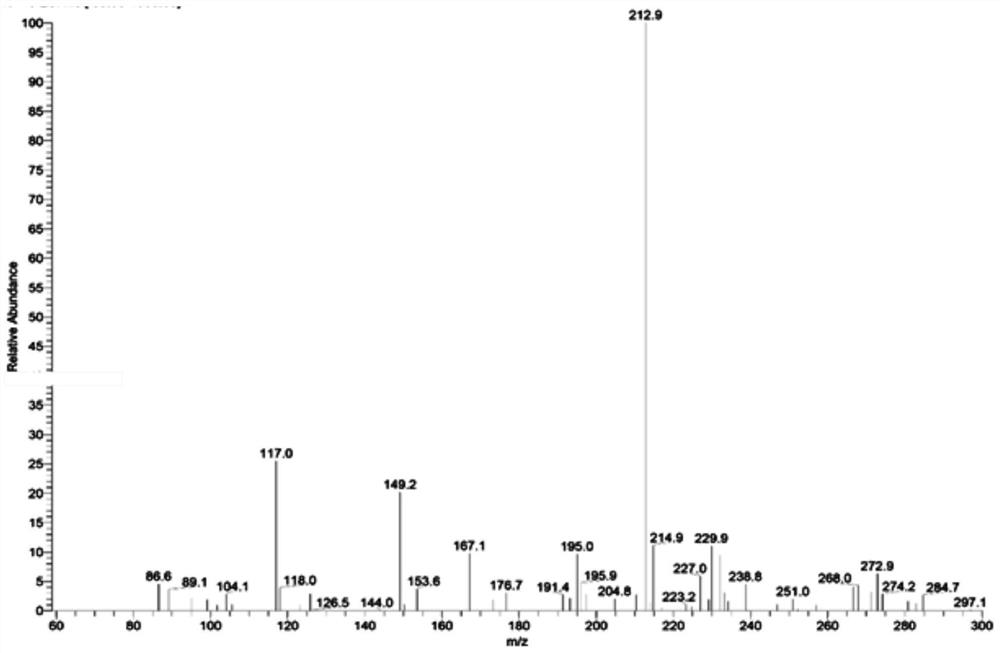

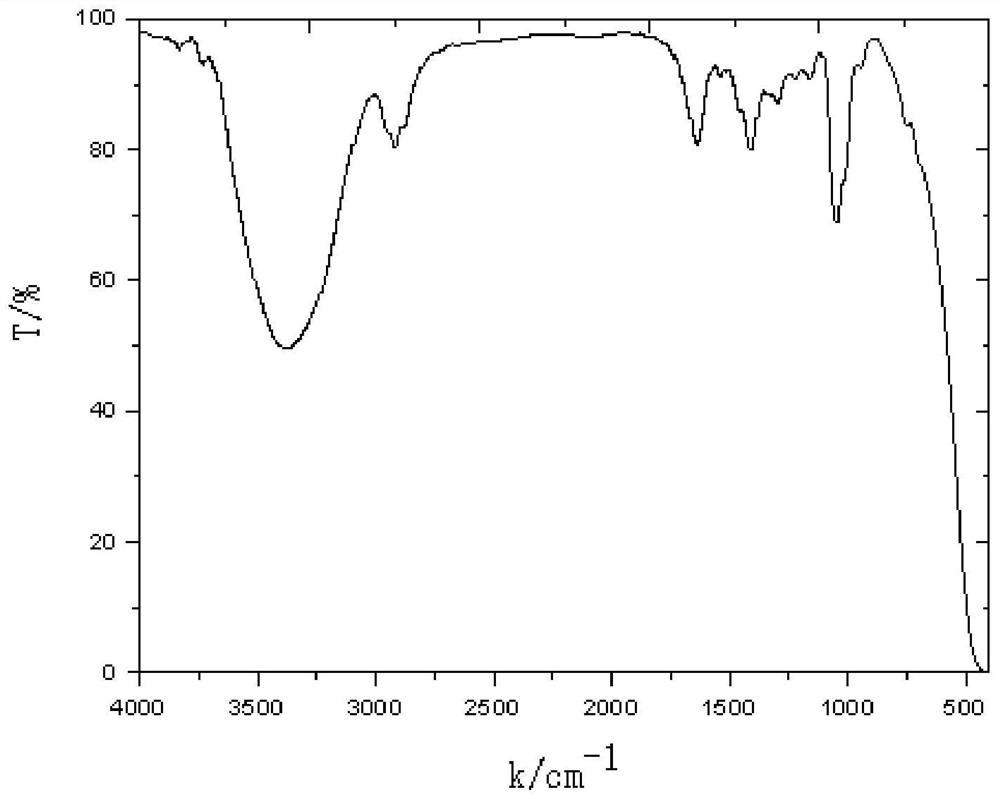

[0055] The mass spectrum of thiopolyols is shown as figure 1 As shown, the infrared spectrum is shown in figure 2 shown.

[0056] 1 H NMR characterization resu...

Embodiment 2

[0061] Embodiment 2 Preparation of thiopolythiol

[0062] Preparation of Thiopolyols:

[0063] (1) Accurately weigh 12g NaOH, 2.4g triethylbenzyl ammonium chloride (TEBA), dissolve in 50ml water and transfer to a 250ml three-necked flask; When the temperature is lower than 5°C, add 9.00 g of 2-mercaptoethanol, stir mechanically, control the temperature of the mixed solution in the reactor to be lower than 10°C, and add 25 g of epichlorohydrin dropwise. (3) TLC monitors that the raw materials are completely reacted, neutralize the mixed solution with concentrated hydrochloric acid to pH = 5-6, distill under reduced pressure to remove small molecules, and remove salt by suction filtration to obtain 16.8 g of a colorless and odorless transparent liquid. Yield 60.2%.

[0064] The structural characterization results of thiopolyols are the same as in Example 1.

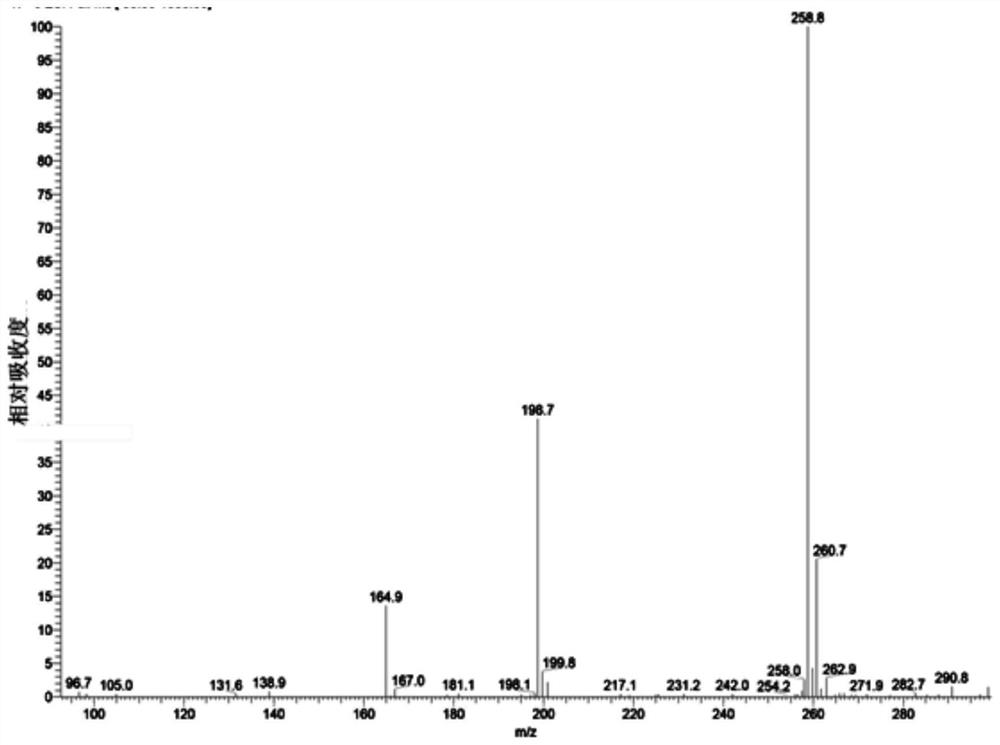

[0065] Preparation of Thiopolythiols:

[0066] (1) Take 10.8g of the product in 1 into a three-necked flask, add 12.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com