Method for extracting sodium tungstate from tungsten-containing waste material

A technology of tungsten waste and sodium tungstate, which is applied in chemical instruments and methods, tungsten compounds, inorganic chemistry, etc., can solve the problems of increased processing costs, cumbersome process, and large tungsten loss, and achieve reduced equipment footprint and simplified production process Process, the effect of enhancing industrial utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

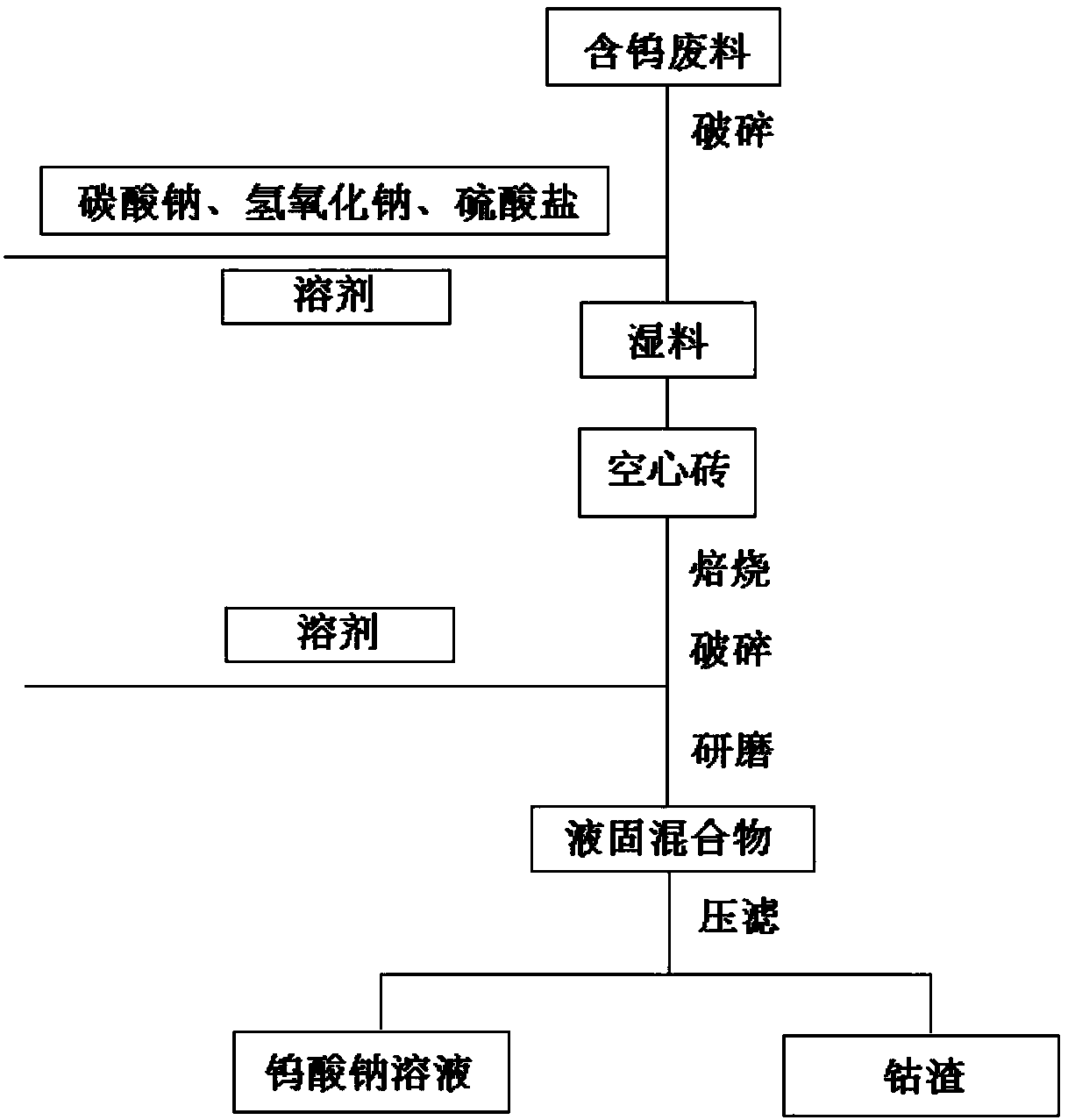

Method used

Image

Examples

Embodiment 1

[0025] The following steps are used to extract sodium tungstate from tungsten-containing waste:

[0026] (1) 30kg of powdery tungsten-containing waste containing 35% tungsten was prepared by mixing high-tungsten-containing waste and low-tungsten-containing waste, and its chromium content was determined to be 7% and the vanadium content to be 2%;

[0027] (2) Add 10.55kg of sodium carbonate, 1.5kg of sodium hydroxide, and 0.67kg of sodium sulfate to the powdery tungsten-containing waste and mix, then add 15kg of raffinate to make a wet material;

[0028] (3) adopt brick press machine to make described wet material into hollow brick, dry naturally;

[0029] (4) Send the dried hollow bricks into the trolley furnace, bake at 900°C for 60 minutes, and then drop to room temperature within about 240 minutes;

[0030] (5) Use a jaw crusher to break the hollow brick obtained in step (4) into blocks, add raffinate to make the liquid-solid ratio reach 0.3:1, grind with a ball mill, then...

Embodiment 2

[0032] The following steps are used to extract sodium tungstate from tungsten-containing waste:

[0033] (1) 50kg of powdery tungsten-containing waste containing 60% tungsten was prepared by mixing high-tungsten-containing waste and low-tungsten-containing waste, and its chromium content and vanadium content were determined to be 3% and 2%;

[0034] (2) Add 25kg of sodium carbonate, 5kg of sodium hydroxide, and 0.25kg of sodium sulfate to the powdery tungsten-containing waste and mix, then add 10kg of causticized liquid to make wet material;

[0035] (3) The wet material is made into a hollow brick (similar to briquette) by a lotus root coal machine, and dried naturally;

[0036] (4) Send the dried hollow bricks into the trolley furnace, bake at 600°C for 180 minutes, and then drop to room temperature within about 120 minutes;

[0037] (5) Use a jaw crusher to break the hollow brick obtained in step (4) into blocks, add raffinate to make the liquid-solid ratio reach 1:1, grin...

Embodiment 3

[0039] The following steps are used to extract sodium tungstate from tungsten-containing waste:

[0040] (1) 30kg of powdery tungsten-containing waste containing 10% tungsten was prepared by mixing high-tungsten-containing waste and low-tungsten-containing waste, and its chromium content was determined to be 1%, and the vanadium content was 0.5%;

[0041] (2) Add 6.5kg of sodium carbonate, 0.9kg of sodium hydroxide, and 0.11kg of sodium sulfate to the powdery tungsten-containing waste to mix, then add 9kg of water to make a wet material;

[0042] (3) adopt brick press machine to make described wet material into hollow brick, dry naturally;

[0043] (4) Send the dried hollow bricks into the trolley furnace, bake at 800°C for 120 minutes, and then drop to room temperature within about 200 minutes;

[0044] (5) Use a jaw crusher to break the hollow brick obtained in step (4) into blocks, add water to make the liquid-solid ratio reach 0.5:1, grind with a ball mill, then add water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com