Aerogel gradient thermal insulation material containing endothermic opacifying agent

A technology of thermal insulation material and sunscreen agent, applied in the direction of layered products, etc., can solve the problems of reduced thermal insulation performance, small thermal inertia, insufficient, etc., to achieve the effect of improving strength and solving low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Material application conditions: the high temperature end is 1200°C, the initial temperature of the material is 25°C, the cold end is insulated, and the thickness of the heat insulation material is 5cm. Airgel material is SiO 2 Airgel, pure SiO 2 The airgel material has a density of 110kg / m 3 .

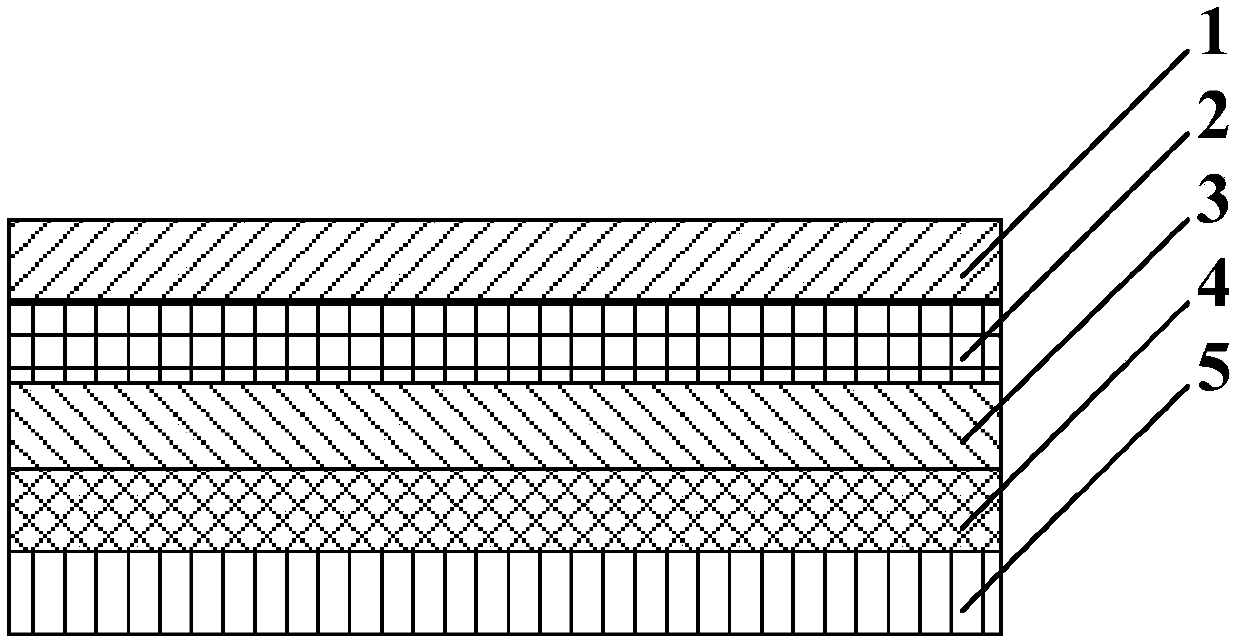

[0032] In this embodiment, the doping of 4 layers of heat-absorbing sunscreens is taken as an example for illustration. In this embodiment, the shell of the heat-absorbing sunscreen agent only uses SiC single material with high temperature resistance and good light-shielding effect. 3.75μm, 4μm, the inner and outer diameter ratio is 0.8; the core material of the endothermic sunscreen is Al-25wt% Si, KNO 3 , erythritol, stearic acid; the volume content of heat-absorbing sunscreens is 8%, 6%, 5% and 4%; the volume content of fiber is 1%. After working for 30 minutes, the back temperature of the airgel gradient thermal insulation material containing heat-absorbing opacifying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com