Corrosion-resisting aluminum alloy material

A technology for corrosion-resistant aluminum alloys and raw materials, applied in the field of corrosion-resistant aluminum alloy materials, can solve problems such as poor corrosion resistance, and achieve the effects of improved corrosion resistance, strong corrosion resistance, and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

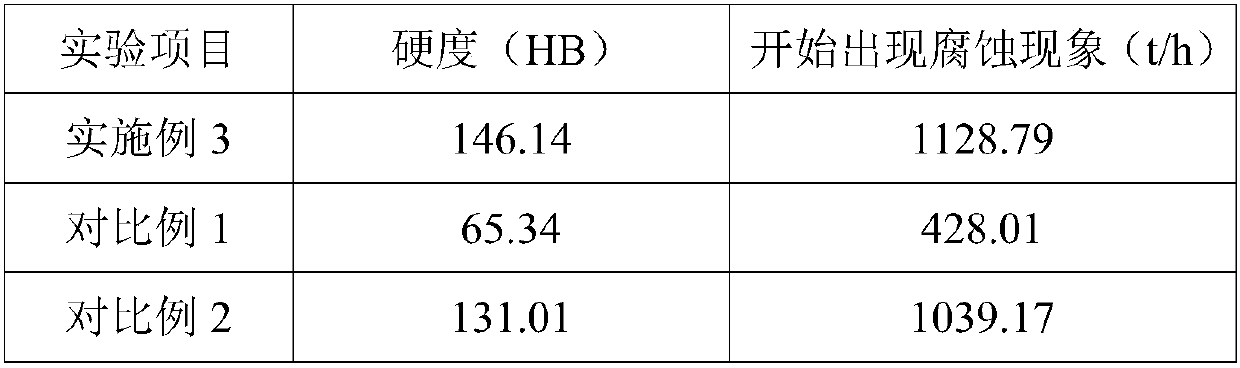

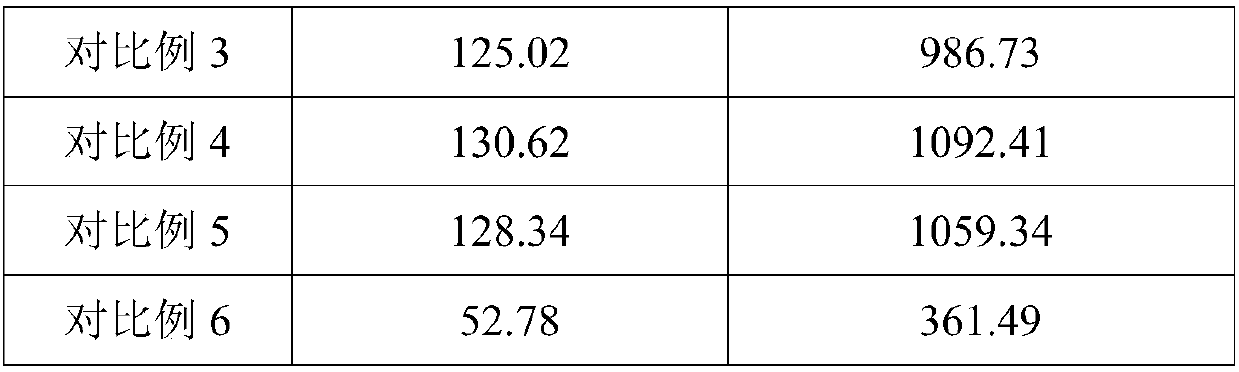

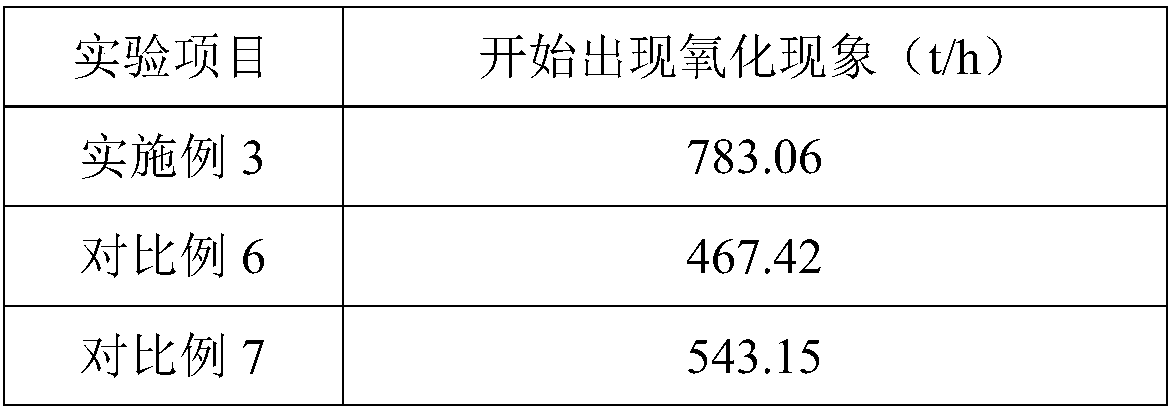

Examples

preparation example Construction

[0015] The preparation method of the corrosion-resistant aluminum alloy material comprises the following steps:

[0016] S1. Melting: After cleaning the prepared materials, use the cast aluminum alloy smelting method to smelt, first melt aluminum, yttrium oxide, praseodymium oxide, copper, and silicon nitride, stir evenly after melting, and then add iron, cobalt, and beryllium , magnesium, titanium, strontium, zinc, chromium, inject graphene, tripotassium phosphate, 2-ethyl methacrylate, p-hydroxybenzenesulfonic acid, barium stearate, 701 powder enhancer after the chemical clearing 6000-7200GS, ultrasonic power of 400-600W, temperature of 62-78°C, and rotation speed of 200-300r / min were used for constant temperature melting to obtain a crude aluminum alloy melt by constant temperature melting for 40-75min;

[0017] S2. Refining: when the temperature reaches 740-790°C, the aluminum alloy crude melt is refined: the scum on the surface of the aluminum alloy crude melt in the furn...

Embodiment 1

[0022] A corrosion-resistant aluminum alloy material, in parts by weight, comprising the following raw materials: 212 parts of aluminum, 7.2 parts of yttrium oxide, 2 parts of praseodymium oxide, 3 parts of copper, 4 parts of iron, 10 parts of cobalt, 2 parts of beryllium, and 8 parts of magnesium 5 parts of titanium, 4 parts of strontium, 12 parts of zinc, 3 parts of chromium, 12 parts of silicon nitride, 1 part of graphene, 1.8 parts of tripotassium phosphate, 1 part of ethyl methacrylate, p-hydroxybenzenesulfonic acid 1.8 parts, 1.5 parts of barium stearate, 1.7 parts of 701 powder enhancer;

[0023] The preparation method of the corrosion-resistant aluminum alloy material comprises the following steps:

[0024] S1. Melting: After cleaning the prepared materials, use the cast aluminum alloy smelting method to smelt, first melt aluminum, yttrium oxide, praseodymium oxide, copper, and silicon nitride, stir evenly after melting, and then add iron, cobalt, and beryllium , magn...

Embodiment 2

[0029] A corrosion-resistant aluminum alloy material, in parts by weight, comprising the following raw materials: 285 parts of aluminum, 10 parts of yttrium oxide, 4 parts of praseodymium oxide, 5 parts of copper, 6 parts of iron, 14 parts of cobalt, 3 parts of beryllium, and 12 parts of magnesium 8 parts of titanium, 6 parts of strontium, 16 parts of zinc, 5 parts of chromium, 18 parts of silicon nitride, 1.5 parts of graphene, 5 parts of tripotassium phosphate, 1.8 parts of ethyl methacrylate, p-hydroxybenzenesulfonic acid 4.2 parts, 3 parts of barium stearate, 2.6 parts of 701 powder enhancer;

[0030] The preparation method of the corrosion-resistant aluminum alloy material comprises the following steps:

[0031]S1. Melting: After cleaning the prepared materials, use the cast aluminum alloy smelting method to smelt, first melt aluminum, yttrium oxide, praseodymium oxide, copper, and silicon nitride, stir evenly after melting, and then add iron, cobalt, and beryllium , mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com