TiO2-coated CoNi nanoparticle of york-shell structure and preparation method of nanoparticle

A technology of nano-microspheres and layer structure, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that are not suitable for nano-microspheres, achieve good magnetic and electrical properties, and structure Uniform distribution and good matching performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

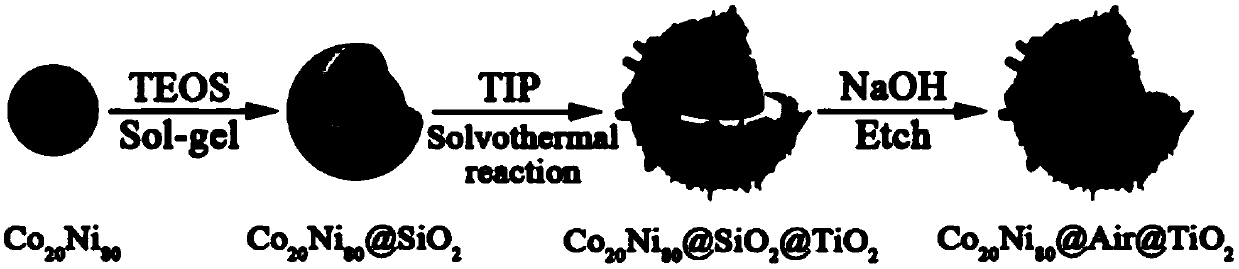

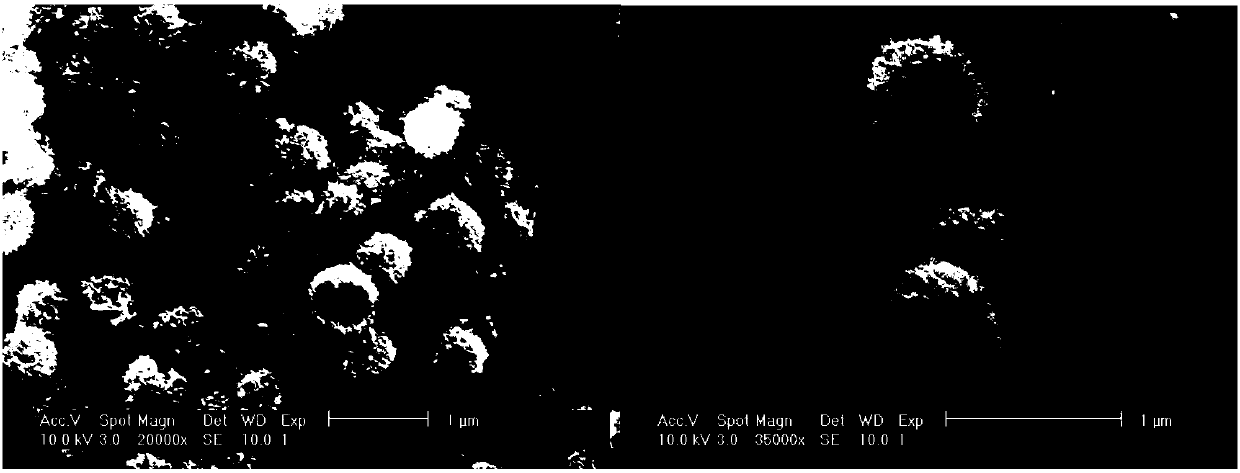

[0035] Such as Figure 1-8 As shown, a york-shell structure CoNi@TiO 2 Nano microspheres, including a CoNi alloy particle core structure, a shell structure and a hollow layer structure, the core structure is mainly a cobalt-nickel alloy composite material, the shell structure is mainly titanium dioxide, and the hollow layer structure is mainly alkali-treated The hollow structure formed after the silicon dioxide.

[0036] A york-shell structure CoNi@TiO 2 The preparation method of nano microsphere, comprises the steps:

[0037] Step 1, material preparation: prepare cobalt acetate, nickel acetate, sodium hydroxide and ethylene glycol solvent, wherein, the above-mentioned materials are used to prepare CoNi alloy particle core structure; prepare diethylenetriamine, isopropyl titanate and isopropyl titanate Propanol reaction solvent, wherein the above-mentioned materials are used to prepare the shell structure; ethanol, distilled water and ammonia water are prepared, wherein the...

Embodiment 2

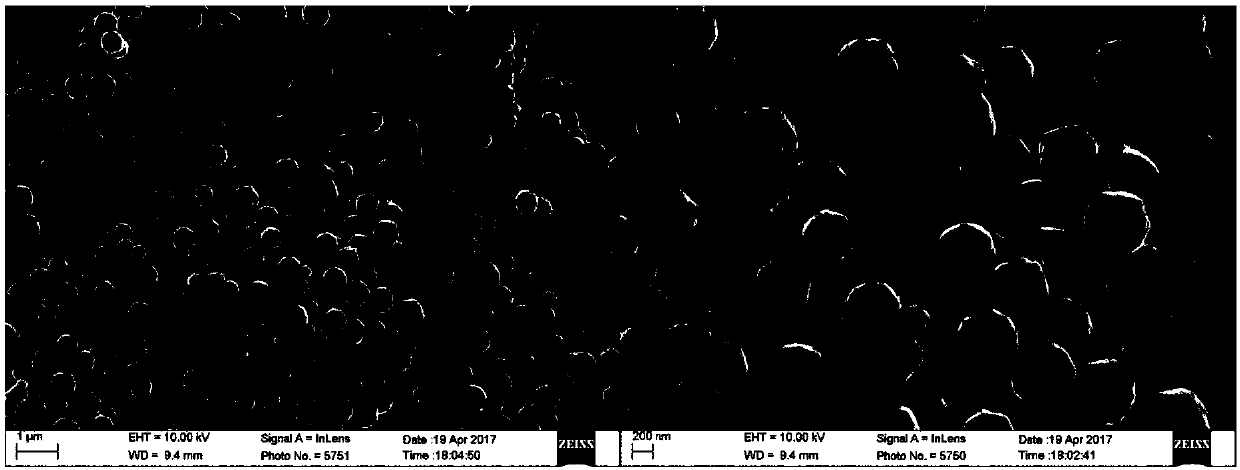

[0048] In this example, in step 2, 0.5g of cobalt acetate and 2.0g of nickel acetate are added to 250g of ethylene glycol solution; 4.0g of sodium hydroxide is added to the mixed solution, and a mechanical stirrer is used under the condition of 720r / min Stir for 60 minutes to form a uniformly mixed dark green solution; transfer all the dark green solution to a PTFE-lined reaction kettle with a volume of 500mL, fill it with nitrogen and seal it, and place it in an oven; in the oven, the temperature is controlled at 200°C React for 12 hours. After the reaction is over, cool to room temperature, collect the gray-black solid phase by magnetic decantation, rinse 6 times with ethanol solution with a volume fraction of 95%, and dry to constant weight at 60°C in a vacuum drying oven; The gray-black powder that obtains carries out characteristic analysis, figure 2 The scanning photo of the cobalt-nickel alloy particle prepared for the present embodiment, Figure 4 XRD diffraction pat...

Embodiment 3

[0050] In this example, in step 2, 1.0 g of cobalt acetate and 4.0 g of nickel acetate are added to 250 g of ethylene glycol solution; 8.0 g of sodium hydroxide is added to the mixed solution, and a mechanical stirrer is used at 720 r / min Stir for 60 minutes to form a uniformly mixed dark green solution; transfer all the dark green solution to a PTFE-lined reaction kettle with a volume of 500mL, fill it with nitrogen and seal it, and place it in an oven; in the oven, the temperature is controlled at 200°C React for 12 hours. After the reaction is over, cool to room temperature, collect the gray-black solid phase by magnetic decantation, rinse 6 times with ethanol solution with a volume fraction of 95%, and dry to constant weight at 60°C in a vacuum drying oven; The obtained gray-black powder was analyzed for electromagnetic properties. Other than that, it was the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com