Inorganic solid electrolyte-cellulose composite diaphragm and preparation method thereof

A technology of solid electrolyte and composite diaphragm, applied in the direction of circuits, electrical components, battery components, etc., can solve the problems of cellulose diaphragm thickness, poor mechanical strength, large pores, etc., and achieve convenient preparation, good wettability, and pore structure evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

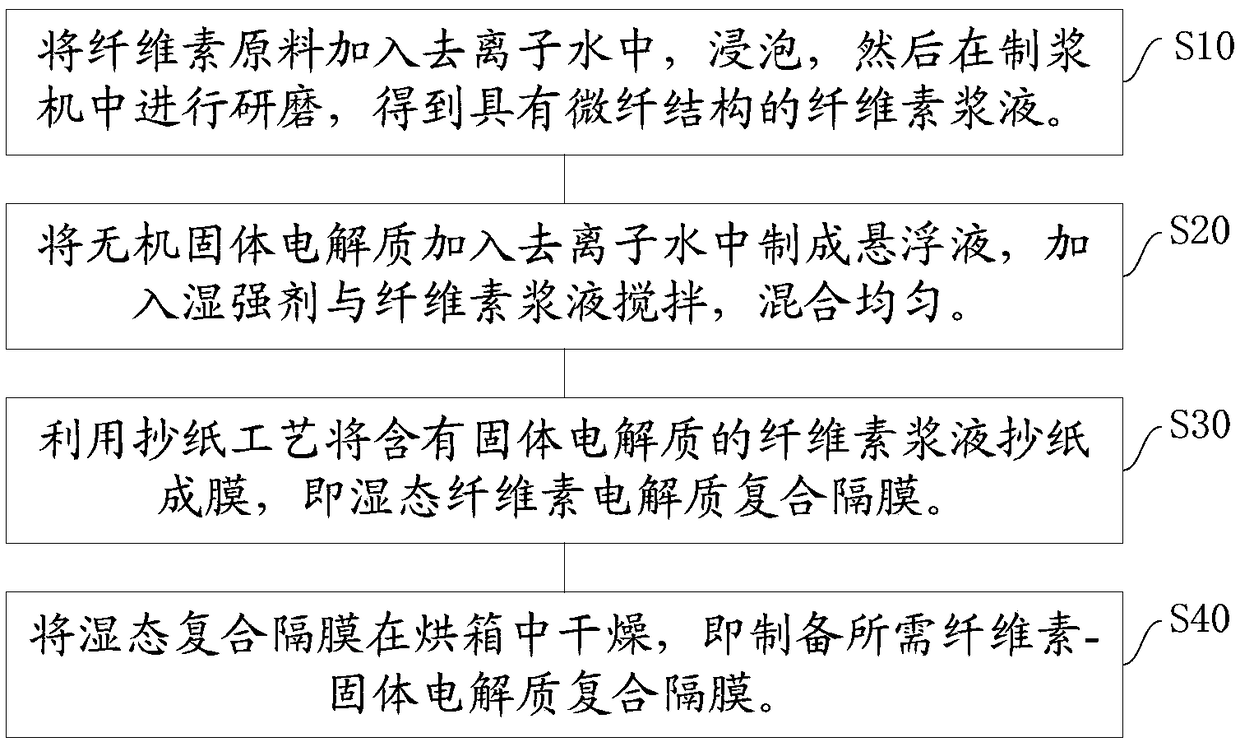

[0027] figure 1 Example 1 of the present invention provides a schematic flow chart of a preparation method of an inorganic solid electrolyte-cellulose composite separator, as shown in figure 1 Shown, described preparation method comprises:

[0028] S10, adding the cellulose raw material into deionized water, soaking it, and then grinding it in a pulper to obtain a cellulose slurry with a microfibrous structure.

[0029] Specifically, the cellulose raw material includes one or more mixed pulps of wood pulp, hemp pulp, cotton pulp or bamboo pulp. Soak in deionized water for 24 hours, then grind in a pulper, the grinding speed is 1-20,000 / rev, the concentration of the prepared cellulose slurry is 1wt%-50wt%, the obtained cellulose slurry has a microfibrous structure, its The diameter of cellulose is 200-500nm.

[0030] S20, adding the inorganic solid electrolyte into deionized water to make a suspension, adding a wet strength agent and stirring the cellulose slurry, and mixing...

Embodiment 2

[0040] The preparation method of the inorganic solid electrolyte-cellulose composite diaphragm provided in Example 2 includes the following steps:

[0041] 1) Add 10 g of cotton pulp to 1 L of deionized water, soak for 24 hours, and then grind in a pulper at 20,000 rpm to obtain a cotton pulp cellulose slurry with a concentration of 2 wt % and a cellulose diameter of 500 nm.

[0042] 2) Add 5g lithium aluminum titanium phosphate (LATP) inorganic solid electrolyte to 500mL deionized water to make a suspension, add 0.5g chitosan, stir vigorously with the cellulose slurry, and mix well;

[0043] 3) Using the papermaking process to make paper from cellulose slurry containing solid electrolyte into a film, that is, a wet cellulose electrolyte composite diaphragm;

[0044] 4) drying the wet composite separator in an oven at 80°C to prepare a cellulose-solid electrolyte composite separator with a thickness of 20 μm;

[0045] The diaphragm acts as a diaphragm and an electrolyte at th...

Embodiment 3

[0047] The preparation method of the inorganic solid electrolyte-cellulose composite diaphragm provided in Example 3 includes the following steps:

[0048] 1) Add 15 g of hemp pulp to 1 L of deionized water, soak for 24 hours, then grind in a pulper at 15,000 rpm to obtain a hemp pulp cellulose slurry with a concentration of 1.5 wt%, and a cellulose diameter of 200 -500nm.

[0049] 2) Add 5g lithium aluminum germanium phosphate (LAGP) inorganic solid electrolyte to 500ML deionized water to make a suspension, add 0.6g chitosan, stir vigorously with the cellulose slurry, and mix well;

[0050] 3) Using the papermaking process to make paper from cellulose slurry containing solid electrolyte into a film, that is, a wet cellulose electrolyte composite diaphragm;

[0051] 4) The composite separator was dried in an oven at 50° C. to prepare a cellulose / solid electrolyte composite separator with a thickness of 30 μm.

[0052] The diaphragm acts as a diaphragm and an electrolyte at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com