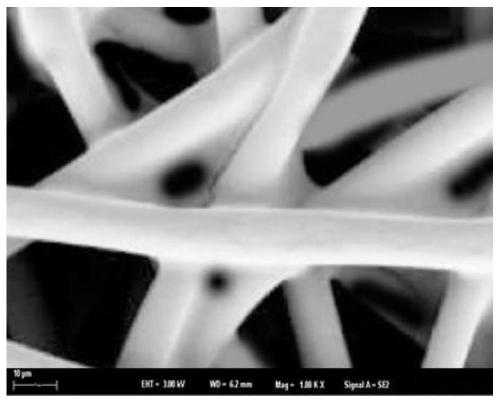

Finishing process of moisture-absorbing and sweat-wicking polyester non-woven fabrics

A polyester non-woven fabric, moisture absorption and perspiration technology, applied in fiber processing, textiles and papermaking, liquid repellent fibers, etc., can solve the problems of poor hygroscopicity and poor hydrophilicity of PET fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

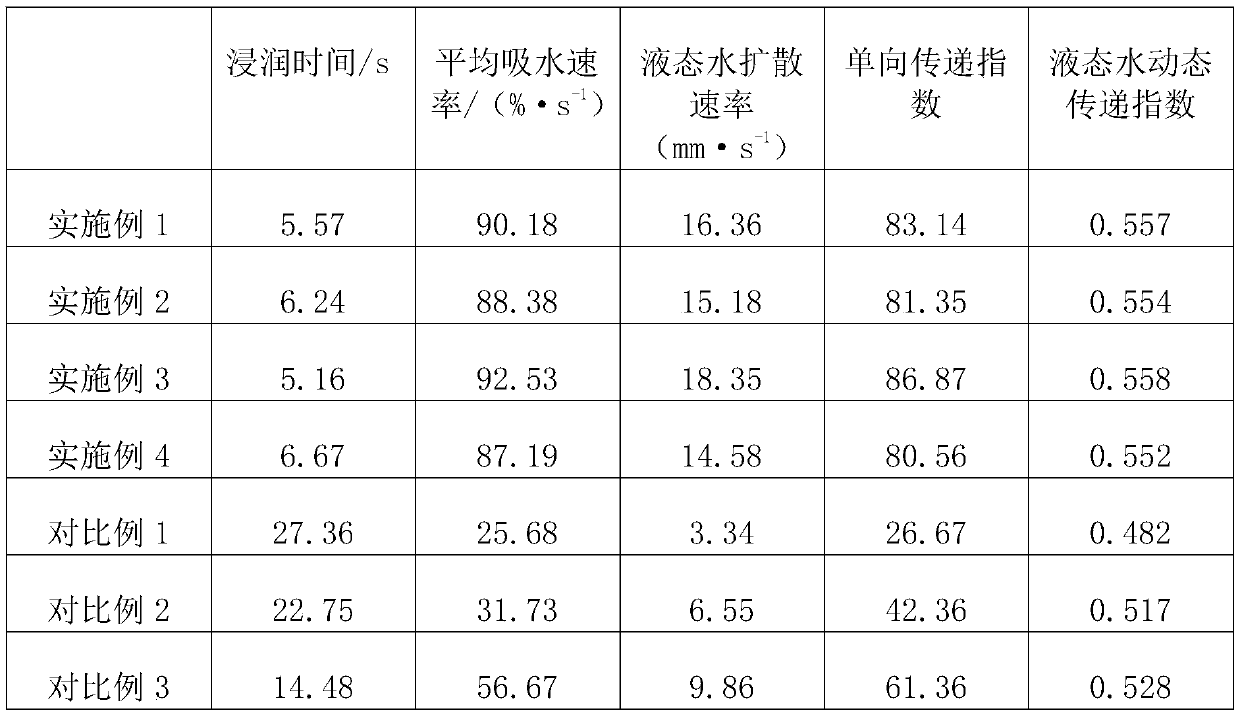

Embodiment 1

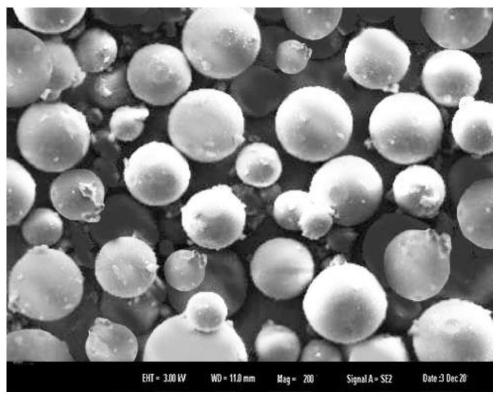

[0028] The preparation method of modified zeolite comprises the following steps:

[0029] Mix the silane coupling agent KH560 and deionized water evenly according to the mass ratio of 1:20, add dropwise acetic acid to adjust the pH of the system to 2.5, stir and hydrolyze for 1.5 hours, and obtain the hydrolyzed solution of the silane coupling agent;

[0030] Take zeolite and add it to the hydrolyzate, the mixing mass volume ratio of zeolite and hydrolyzate is 1g / 50mL, heat in a water bath to 70°C, stir and react for 3h, centrifuge, wash and dry to obtain surface-modified zeolite;

[0031] Add sodium alginate to deionized water, stir and dissolve to prepare a sodium alginate solution with a mass concentration of 5%, add an acid catalyst to the sodium alginate solution, and the acid catalyst is SnCl 4 The mixture obtained with 10wt% hydrochloric acid aqueous solution according to the ratio of 1mg / 30mL, the amount of acid catalyst added is 0.05wt% of the sodium alginate solution...

Embodiment 2

[0039] The preparation method of modified zeolite comprises the following steps:

[0040] Mix the silane coupling agent KH560 and deionized water evenly according to the mass ratio of 1:10, add dropwise acetic acid to adjust the pH of the system to 3, stir and hydrolyze for 1 hour, and obtain the hydrolyzed solution of the silane coupling agent;

[0041] Take zeolite and add it to the hydrolyzate, the mixing mass volume ratio of zeolite and hydrolyzate is 1g / 40mL, heat in a water bath to 80°C, stir and react for 2.5h, centrifuge, wash and dry to obtain surface-modified zeolite;

[0042] Add sodium alginate to deionized water, stir and dissolve to prepare a sodium alginate solution with a mass concentration of 5%, add an acid catalyst to the sodium alginate solution, and the acid catalyst is SnCl 4 The mixture obtained with 10wt% hydrochloric acid aqueous solution according to the ratio of 1mg / 20mL, the amount of acid catalyst added is 0.05wt% of the sodium alginate solution, a...

Embodiment 3

[0050] The preparation method of modified zeolite comprises the following steps:

[0051] Mix the silane coupling agent KH560 and deionized water evenly according to the mass ratio of 1:15, add dropwise acetic acid to adjust the pH of the system to 2.5, stir and hydrolyze for 2 hours, and obtain the hydrolyzed solution of the silane coupling agent;

[0052] Take zeolite and add it to the hydrolyzate, the mixing mass volume ratio of zeolite and hydrolyzate is 1g / 45mL, heat in a water bath to 75°C, stir and react for 4h, centrifuge, wash and dry to obtain surface-modified zeolite;

[0053] Add sodium alginate to deionized water, stir and dissolve to prepare a sodium alginate solution with a mass concentration of 5%, add an acid catalyst to the sodium alginate solution, and the acid catalyst is SnCl 4 The mixture obtained with 10wt% hydrochloric acid aqueous solution according to the ratio of 1mg / 25mL, the amount of acid catalyst added is 0.05wt% of the sodium alginate solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com