Method for measuring tungsten content in steel

A determination method and technology of tungsten content, applied in the field of chemical analysis, can solve the problem of non-linearity of molybdenum interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

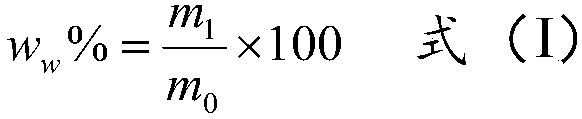

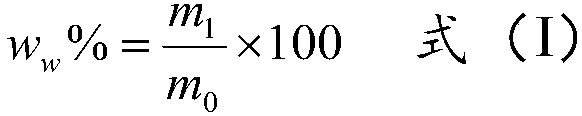

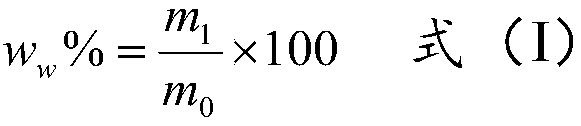

Image

Examples

Embodiment 1

[0088] Detect the steel with sample number YSBC11404-99Cr12W:

[0089] 1) Sampling and preparation: Take samples and prepare according to GB / T 20066 or appropriate national standards.

[0090] 2) Sample weight: Weigh the sample according to Table 1 (accurate to 0.0001g).

[0091] 3) Sample dissolution:

[0092] Make a reagent blank along with the sample.

[0093] Put the sample into a 300mL ordinary glass or quartz conical flask, add an appropriate amount of hydrochloric acid, nitric acid and mixed acid in appropriate proportions and heat at low temperature until the sample is completely dissolved. Add 25.0 ml of sulfuric acid and phosphoric acid mixed acid {when processing the sample in an ordinary glass Erlenmeyer flask, add (1+2) sulfuric acid mixed acid [sulfuric acid (ρ1.84g / ml) and phosphoric acid (ρ1.70g / ml) by volume 1 : 2 ratio mixing]; when processing the sample in the quartz conical flask, add (1+5) sulfur-phosphorus mixed acid [sulfuric acid (ρ1.84g / ml) and phos...

Embodiment 2

[0112] Referring to Example 1, the steel with the sample number BH1016-1Cr11Ni2W2MoV was tested, and the steel sample was tested twice, and the calculated tungsten contents were: 1.791wt% and 1.771wt%.

Embodiment 3

[0114] Referring to Example 1, the steel with the sample number YSBC11203-99 4Cr3SiMnMoV was tested, and the steel sample was tested twice, and the calculated tungsten contents were: 0.945wt% and 0.944wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com