Preparation method of polypyrrole coated lithium titanium phosphate anode material

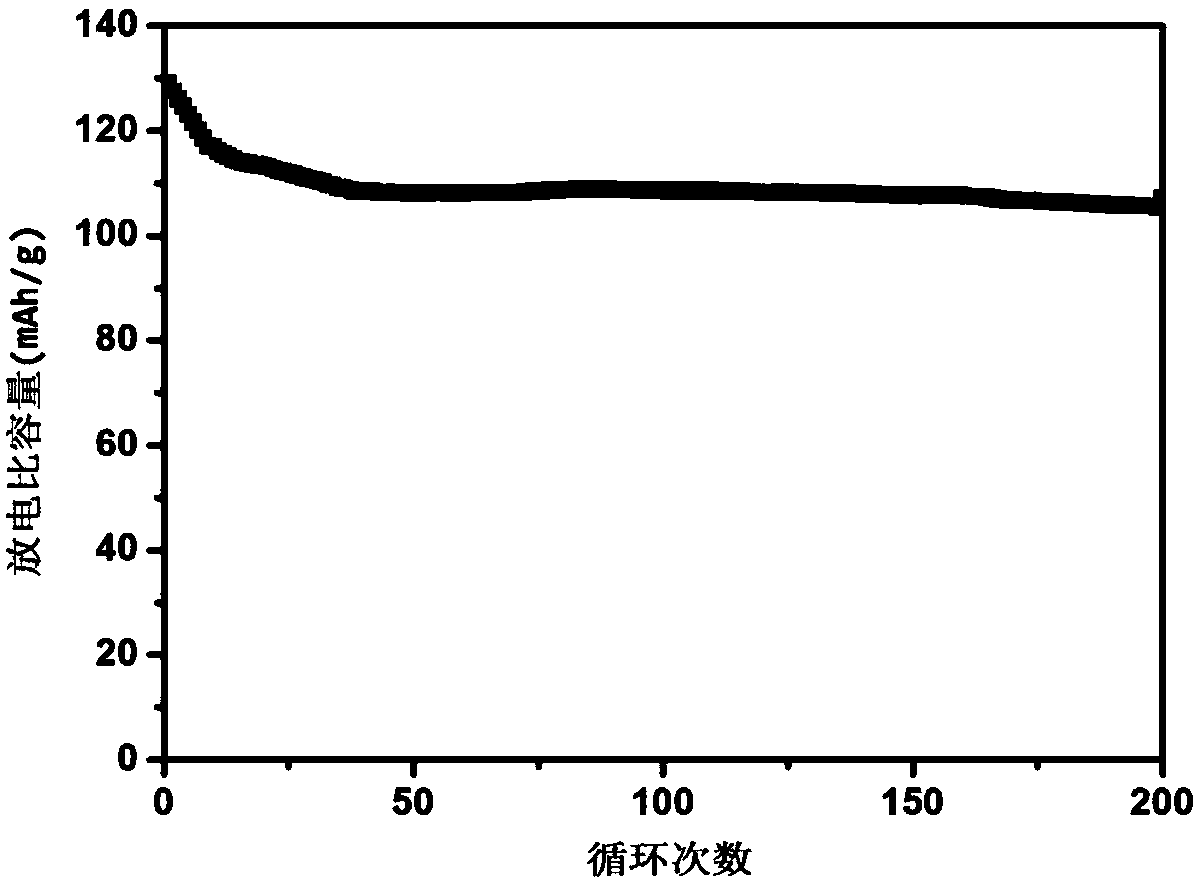

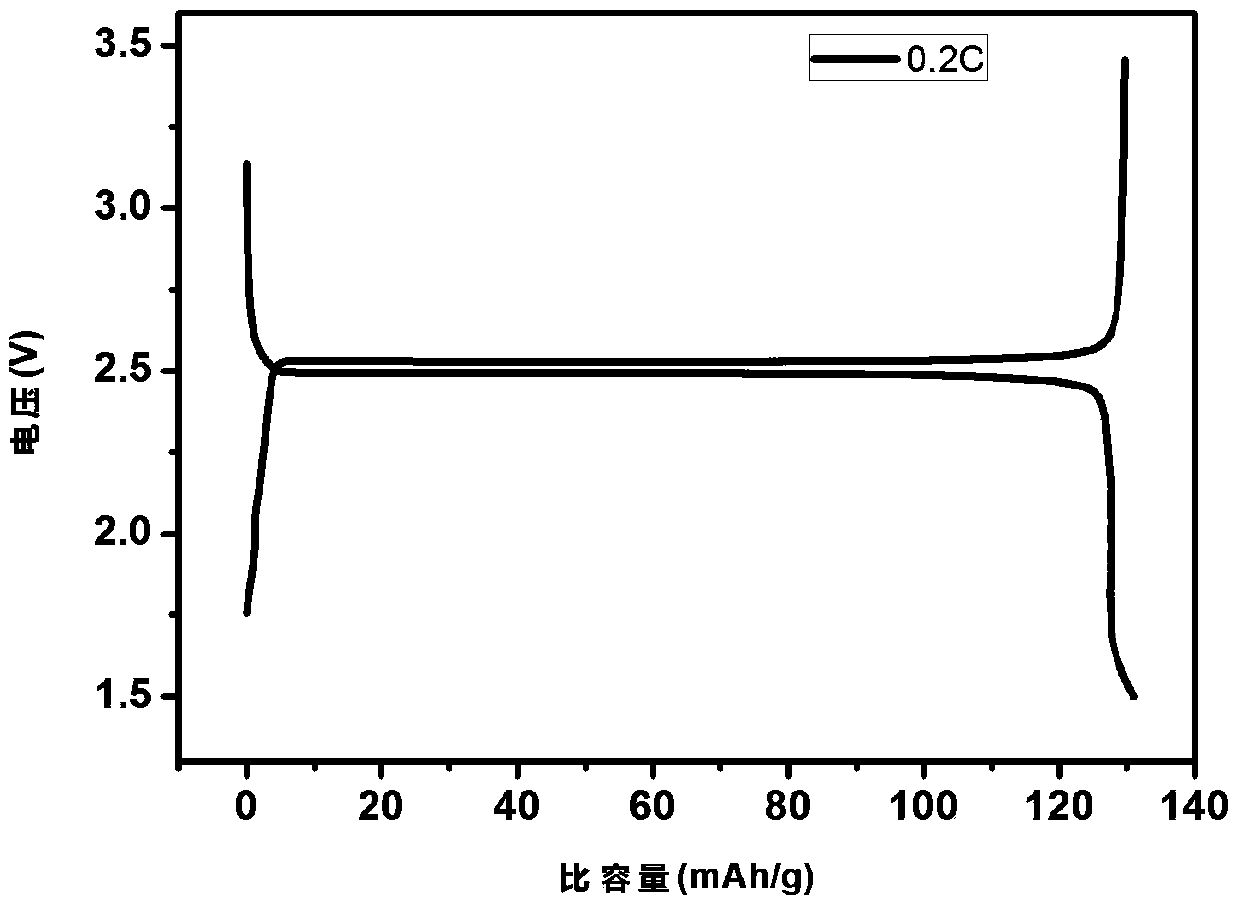

A technology for coating lithium titanium phosphate and negative electrode materials with polypyrrole, which is applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as battery capacity decay, and achieve increased electrical conductivity, good cycle stability, and electrical conductivity. and improved electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A polypyrrole-coated titanium lithium phosphate negative electrode material and a preparation method thereof, comprising the following steps:

[0037] (1) Add ammonia water dropwise to the aqueous solution of polypyrrole polystyrene sulfonic acid with a solid content of 2.1wt%, adjust the pH value of the solution to 7, and obtain solution A; wherein, lithium titanium phosphate negative electrode material and polypyrrole The mass ratio is 100:1;

[0038] (2) Mix and dissolve lithium carbonate, tetrabutyl titanate, and lithium dihydrogen phosphate in deionized water, and add it to solution A prepared in step (1), wherein lithium in lithium carbonate, titanium in tetrabutyl titanate The molar ratio between phosphorus and lithium dihydrogen phosphate is 1:2:2; stir and disperse at a high speed of 2300 rpm in a high-speed mixer for 5 minutes to obtain slurry B, and the solid content of the slurry is 25wt%;

[0039] (3) Stir the slurry B obtained in step (2) for 6 hours in a w...

Embodiment 2

[0043] A polypyrrole-coated titanium lithium phosphate negative electrode material and a preparation method thereof, comprising the following steps:

[0044] (1) Add ammonia water dropwise to an aqueous solution of polypyrrole polystyrene sulfonic acid with a solid content of 2.0wt%, adjust the pH value of the solution to 8, and obtain solution A; wherein, lithium titanium phosphate negative electrode material and polypyrrole The mass ratio is 85:1;

[0045] (2) Mix and dissolve lithium carbonate, titanium dioxide, and ammonium dihydrogen phosphate in deionized water, and add it to the solution A prepared in step (1), in which lithium in lithium carbonate, titanium in titanium dioxide, and phosphorus in ammonium dihydrogen phosphate The molar ratio between is 1:2:2.1; In the high-speed mixer with the speed of 3000rpm high-speed stirring dispersion 5min, obtain slurry B, the solid content of slurry is 30wt%;

[0046] (3) Stir the slurry B obtained in step (2) for 8 hours in a ...

Embodiment 3

[0050] (1) Add ammonia water dropwise to an aqueous solution of polypyrrole polystyrenesulfonic acid with a solid content of 2.1wt%, and adjust the pH value of the solution to 9 to obtain solution A; wherein, lithium titanium phosphate negative electrode material and polypyrrole The mass ratio is 95:1;

[0051] (2) Mix and dissolve lithium sulfate, titanium phosphate, and ammonium dihydrogen phosphate in deionized water, and add it to the solution A prepared in step (1), in which lithium in lithium sulfate, titanium in titanium phosphate, and ammonium dihydrogen phosphate The molar ratio between the phosphorus is 1:3:4; In the high-speed mixer with the speed of 4000rpm high-speed stirring dispersion 3min, obtain slurry B, the solid content of slurry is 35wt%;

[0052] (3) Stir the slurry B obtained in step (2) for 9 hours in a water bath at 75°C to obtain a gel; dry the gel at 70°C under vacuum, grind and pulverize to obtain a precursor;

[0053] (4) The precursor obtained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com