Preparation method of hollow mesoporous silica microsphere-reinforced epoxy resin composite material

A mesoporous silica and epoxy resin technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of affecting the dispersion and interface compatibility of the matrix resin, affecting material performance, and poor interface compatibility, etc., to achieve Solve the problem of interface compatibility, improve the overall performance, and reduce the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

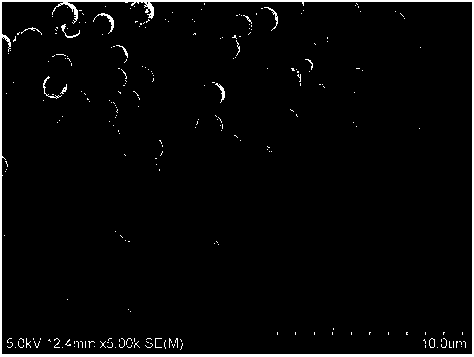

[0023] (1) Dissolve the soft templating agent and the hard templating agent in an aqueous solution of ethanol, add ammonia solution, and the absolute ethanol accounts for 25% by weight of the mixed solution, sonicate for 0.5h, stir at 30°C for 4h, and then use normal Ethyl silicate is used as a silicon source, and the mass ratio of ethyl orthosilicate to the hard template is 1:1, and is added dropwise to the mixed solution. The mass ratio of the soft template, the hard template, ammonia water and orthosilicate is 0.4:1.8:1:1.8, stirred at 40°C for 24h, then transferred the reaction product to a hydrothermal reaction kettle and placed in an oven at 60°C, crystallized for 24h, then washed, filtered, and dried at 60°C for 6h , the obtained powder was placed in a 550°C horse-boiling furnace and calcined for 500min to prepare hollow mesoporous silica microspheres.

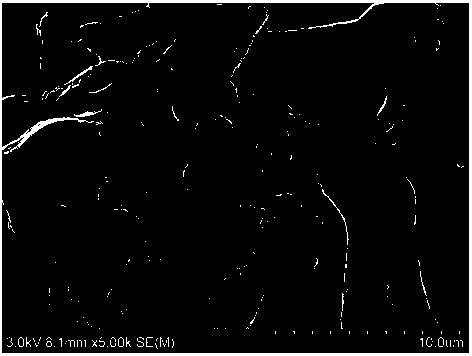

[0024] (2) Dry the hollow mesoporous silica microspheres prepared in step (1) at 150°C for 3 hours, and then place th...

Embodiment 2

[0034] Except that the amount of coupling-treated hollow mesoporous silica microspheres prepared in step (2) used in step (3) was changed to 2.0 g, other steps were kept the same as in Example 1.

Embodiment 3

[0036] Except that the amount of coupling-treated hollow mesoporous silica microspheres prepared in step (2) used in step (3) was changed to 3.0 g, other steps were kept the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com