A progressive laser lift-off process for micron-sized sapphire substrates

A sapphire substrate, laser lift-off technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of reduced device process yield and self-reliability, increased device leakage, material damage, etc., and achieves the peeling process yield rate Improve, reduce process complexity, reduce the effect of high pressure nitrogen impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A progressive micron-scale sapphire substrate laser lift-off process provided by the present invention specifically includes the following steps:

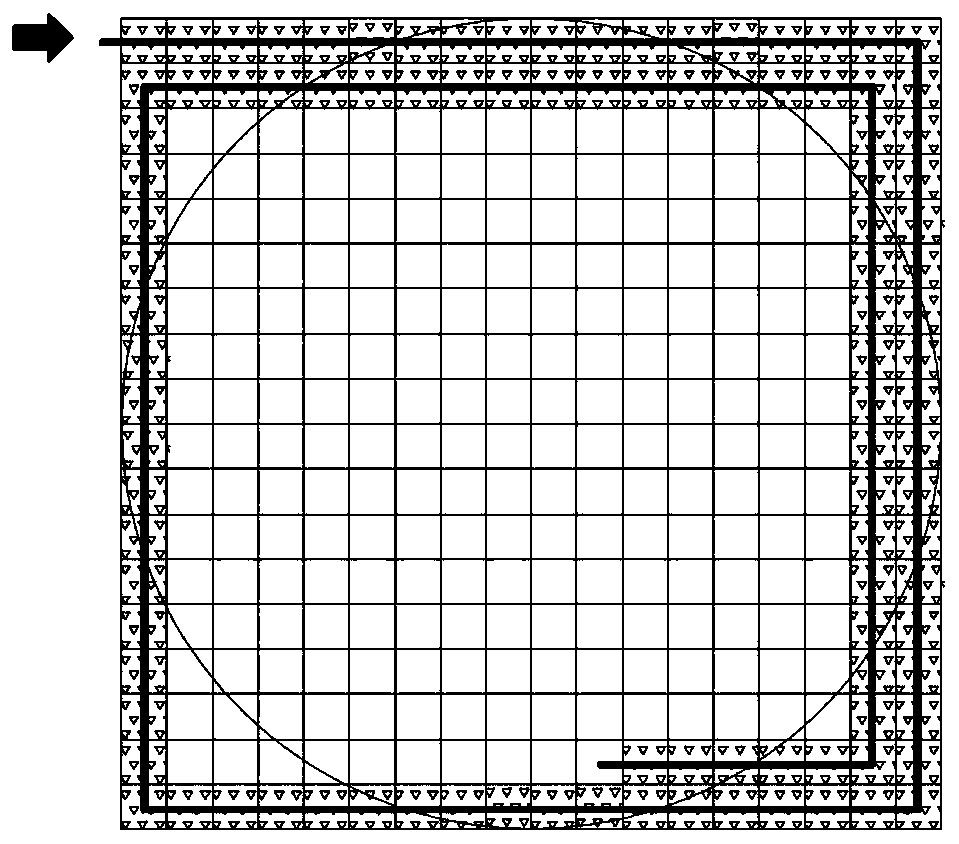

[0029] (1) Firstly, the GaN LED epitaxial layer 101 is prepared on the sapphire substrate 100 by epitaxial growth method, and the total thickness of the epitaxial layer 101 is controlled at 5-10 microns; including the buffer layer Buffer layer, the unintentionally doped layer U- GaN, heavily doped N-GaN, multiple quantum wells MQW, electron blocking layer EBL, heavily doped P-GaN. The epitaxial growth method can be metal chemical vapor deposition, laser assisted molecular beam epitaxy, laser sputtering, or hydride vapor phase epitaxy. The deposited epitaxial film can be amorphous, polycrystalline, or single crystal structure. The sapphire substrate includes but is not limited to one of the mirror surface or micro-scale / nano-scale patterned sapphire substrate. The preferred solution is the mirror surface sapphire substrate ;...

Embodiment 2

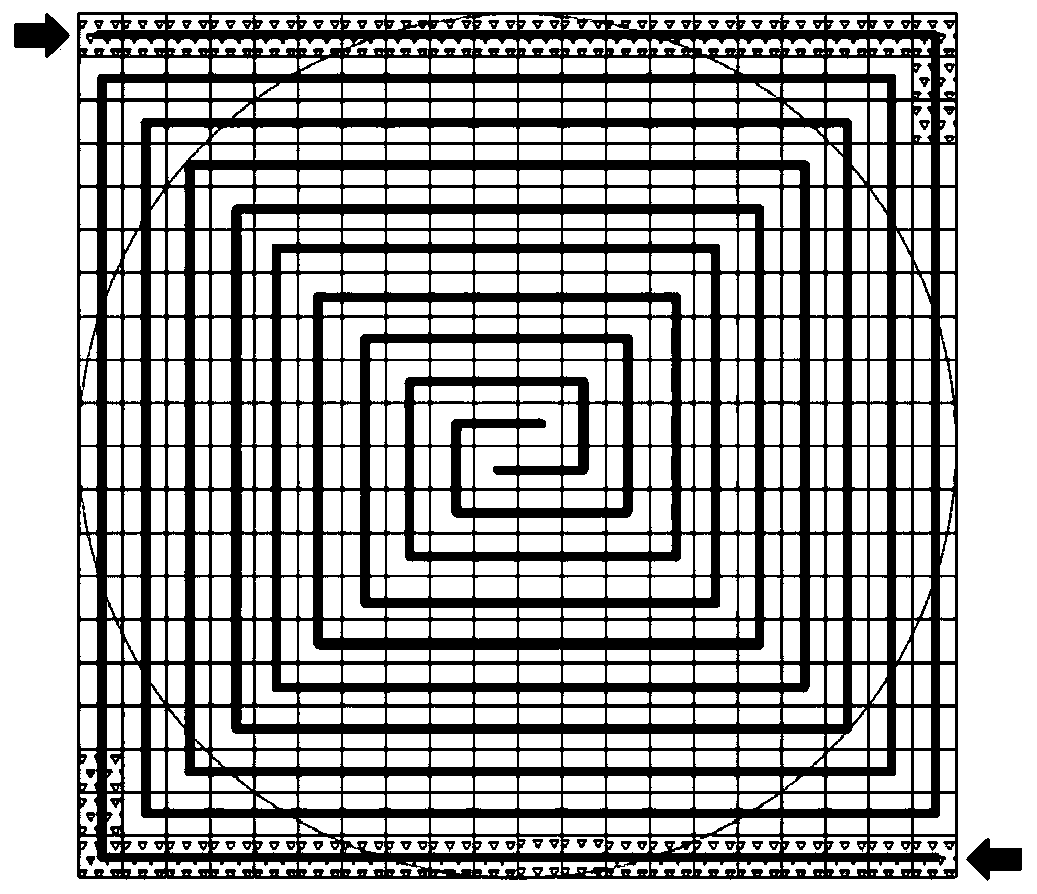

[0034] A progressive micron-scale sapphire substrate laser lift-off process provided by the present invention specifically includes the following steps:

[0035] (1) First, an AlGaN epitaxial layer 101 is prepared on a sapphire substrate 100 by an epitaxial growth method, and the total thickness of the epitaxial layer 101 is controlled at 5-10 microns; including a buffer layer Buffer layer, an AlN layer, and a superlattice structure SL , heavily doped N-AlGaN, multiple quantum well MQW, P-AlGaN, heavily doped P-GaN contact layer. The epitaxial growth method can be metal chemical vapor deposition, laser assisted molecular beam epitaxy, laser sputtering, or hydride vapor phase epitaxy. The deposited epitaxial film can be amorphous, polycrystalline, or single crystal structure. The sapphire substrate includes but is not limited to one of the mirror surface or micron-scale / nano-scale patterned sapphire substrate. The preferred solution is a micron-scale pattern sapphire substrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com