Low-grade heat-driven adsorption type refrigerating and heating pump circulating device adopting chemical reaction and method utilizing same

A technology of chemical reaction and low-grade heat, applied in refrigerators, refrigeration and liquefaction, climate change adaptation, etc., can solve the problems of low cooling capacity and low performance coefficient, and achieve less moving parts, high performance coefficient, stable and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The first gaseous refrigerant used in this embodiment is ammonia, the second gaseous refrigerant is carbon dioxide, the working liquid is propylene glycol, and the adsorbents in the first adsorber and the second adsorber are activated carbon fibers.

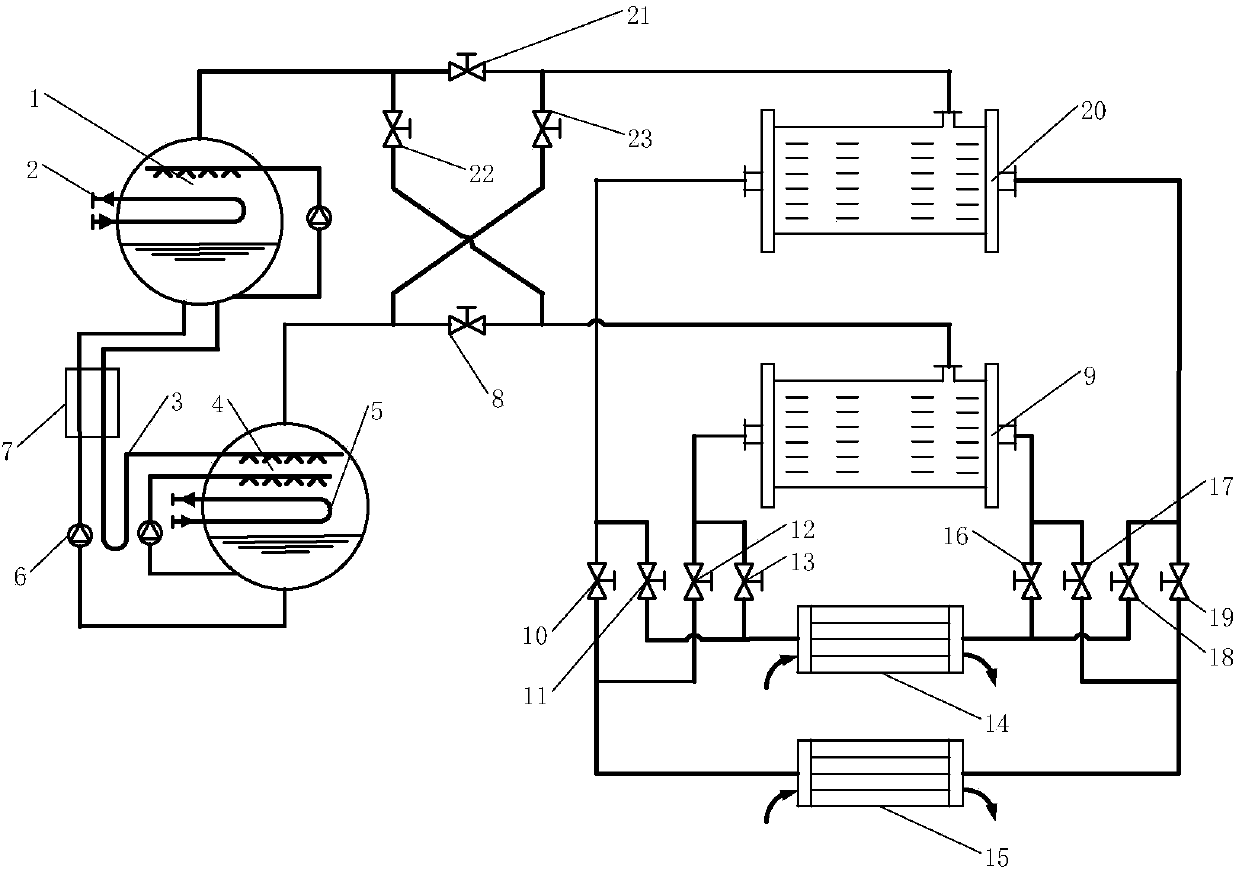

[0075] Such as figure 1 As shown, the circulation device of this embodiment includes a chemical reaction cooler 1, a chemical reaction cooler cooling water or a heat medium water pipeline 2, a U-shaped pipe 3, a chemical reaction evaporator 4, chilled water or a low-temperature heat source pipeline 5, and a solution Pump 6, regenerator 7, second adsorber 9, low-temperature heat exchanger 14, high-temperature heat exchanger 15, first adsorber 20, valves 8, 10-13, 16-19, 21-23;

[0076] The gas inlet of the chemical reaction cooler 1 is connected to the gas inlet / outlet of the first adsorber 20 through a valve 21, and the gas inlet of the chemical reaction cooler 1 is connected to the gas inlet / outlet of the second adsorber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com