Condenser for refrigerator

A technology for condensers and refrigerators, which is applied to evaporators/condensers, household refrigerators, and household refrigeration devices. It can solve problems such as excessive pressure drop, and achieve the goals of reducing heat exchange area, saving materials, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

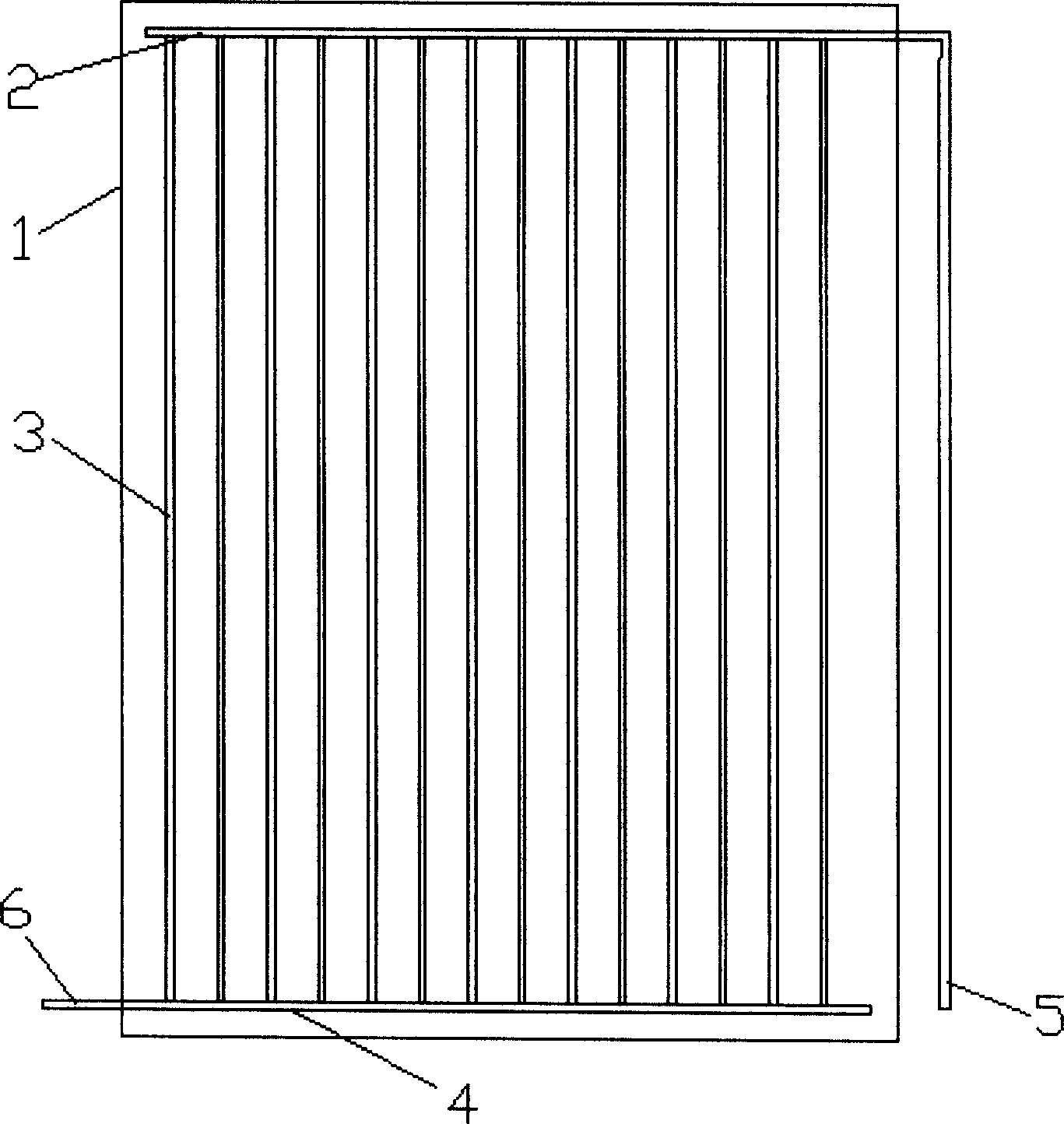

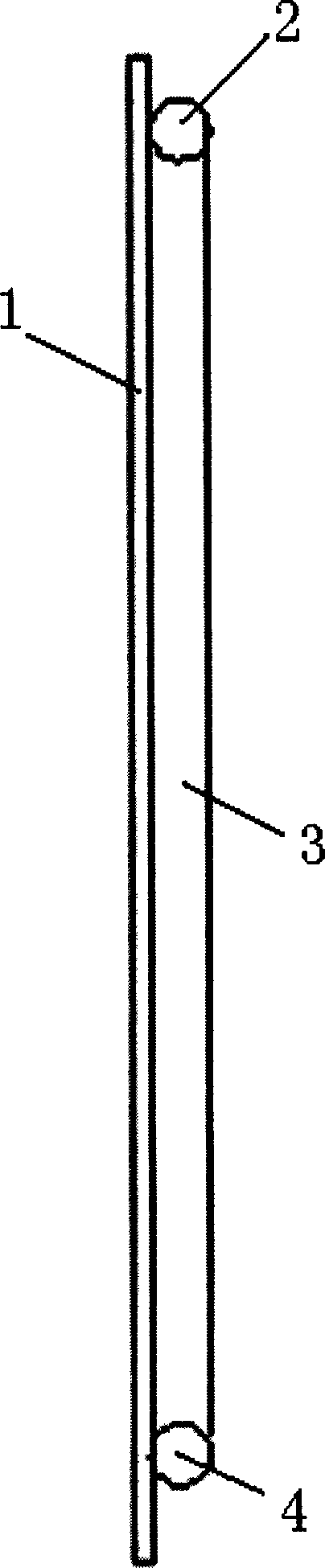

[0011] Such as figure 1 As shown, the condenser is composed of a set of parallel vertical pipes 3, an upper liquid collecting pipe 2, a lower liquid collecting pipe 4 which are respectively connected to the two ends of the vertical pipe, and a radiating plate 1 arranged on one side of the vertical pipe. The diameter of the vertical pipe 3 is generally 1 to 3 mm, and the thickness of the heat dissipation plate is 0.5 to 1 mm. After connecting the vertical pipe to the upper and lower liquid collecting pipes, glue it on the heat sink or fix it in other ways.

[0012] The working process is as follows: the refrigerant enters the condenser from the vertical pipe inlet 5, then enters the upper collecting pipe 2, and then is distributed to the vertical pipes 3. The refrigerant condenses in the vertical pipes and transfers heat to the heat dissipation th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com