Method for preparing TiO2@Au core-shell structure in template method

A technology of core-shell structure and template method, which is applied in the direction of chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of high probability of band gap and electron-hole recombination, and the reaction process cannot be carried out directly. Observation, photocatalytic performance is not greatly improved and other problems, to achieve the effect of uniform size, avoiding gold falling off, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] Preparation of gold sol:

[0029] Take 90ml of ultrapure water, add it into the flask and stir, then add 1ml of 1% HAuCl 4 (chloroauric acid) and let it stir for 1min, add 2ml trisodium citrate solution after 1min, add 1mlNaBH after stirring for 1min 4 and 1ml of trisodium citrate, the wine red solution obtained after stirring for 5min is gold nanoparticles (NaBH 4 Solution preparation method: 0.025g NaBH 4 Dissolve in 20ml of water to obtain NaBH with a concentration of 1.25mg / ml 4 solution; trisodium citrate solution preparation method: 0.224g trisodium citrate is dissolved in 20ml water)

Embodiment 1

[0031] 1. The preparation method of PS@Au, comprising the following steps:

[0032] (1) Dissolve 0.5g of potassium persulfate and 0.06g of sodium styrene sulfonate in 45ml of water and 165ml of alcohol, and heat it to 70 degrees in an oil bath, so that potassium persulfate and sodium styrene sulfonate can be fully dissolved .

[0033] (2) Prepare a mixed liquid of styrene (1.98ml) and divinylbenzene (0.02ml) with a volume ratio of 99:1, add it to the mixed liquid in (1), start timing at the same time, add 30ml after 2min Prepared gold sol.

[0034] (3) Allow the reaction solution in (2) to react at 70° C. for 4 h, and then stop the reaction to obtain purple PS@Au spheres with Tyndall effect.

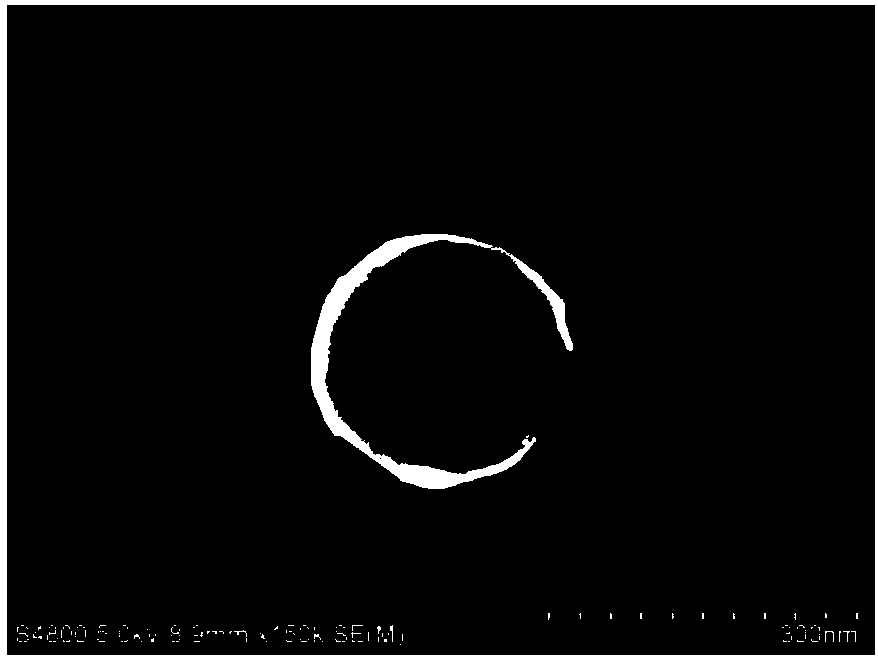

[0035] Label the sample as PS@Au, such as figure 1 Its SEM image.

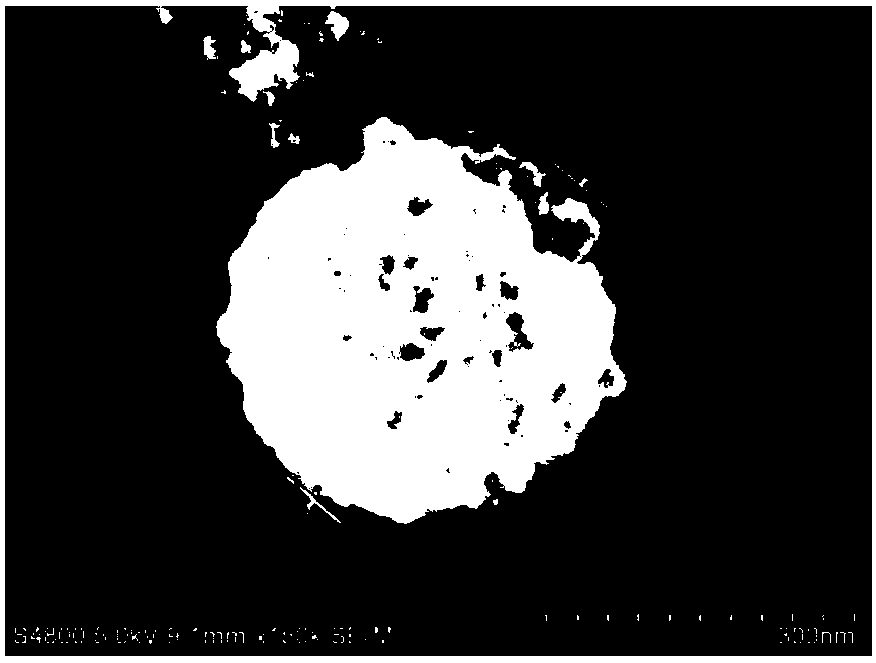

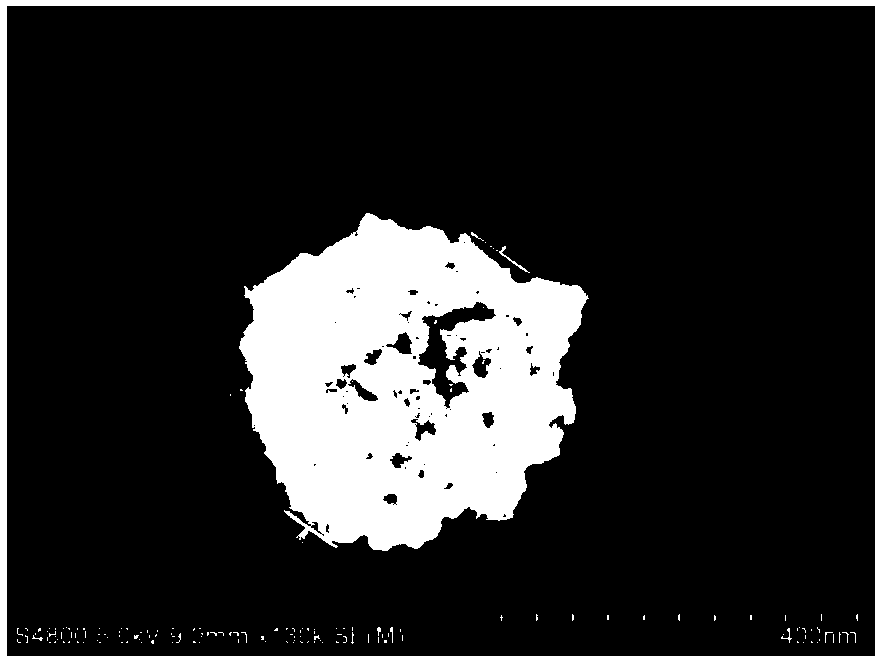

[0036] 2. TiO 2 The preparation method of @PS@Au comprises the following steps:

[0037] (1) The PS@Au pellets prepared in Example 1 were centrifuged and dispersed in absolute ethanol to prepare a 0.01 g / ml PS@Au s...

Embodiment 2

[0044] 1. The preparation method of PS@Au, comprising the following steps:

[0045] (1) Dissolve 0.5g of potassium persulfate and 0.06g of sodium styrene sulfonate in 45ml of water and 165ml of alcohol, and heat it to 70 degrees in an oil bath, so that potassium persulfate and sodium styrene sulfonate can be fully dissolved .

[0046] (2) Prepare a mixed liquid of styrene (1.98ml) and divinylbenzene (0.02ml) with a volume ratio of 99:1, add it to the mixed liquid in (1), start timing at the same time, add 30ml after 2min Prepared gold sol.

[0047] (3) Allow the reaction solution in (2) to react at 70° C. for 4 h, and then stop the reaction to obtain purple PS@Au spheres with Tyndall effect.

[0048] 2. TiO 2 The preparation method of @PS@Au comprises the following steps:

[0049] (1) The PS@Au pellets prepared in Example 1 were centrifuged and dispersed in absolute ethanol to prepare a 0.01 g / ml PS@Au solution.

[0050] (2) Disperse 0.1g polyvinylpyrrolidone (PVP) in a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com