Method for preparing silicon carbide nanometer crystal whiskers from crystalline silicon cutting waste mortar

A technology of crystalline silicon cutting and nano-whiskers, which is applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of low preparation efficiency, high cost, complicated process, etc., and achieve the goal of preparation The effect of long time, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

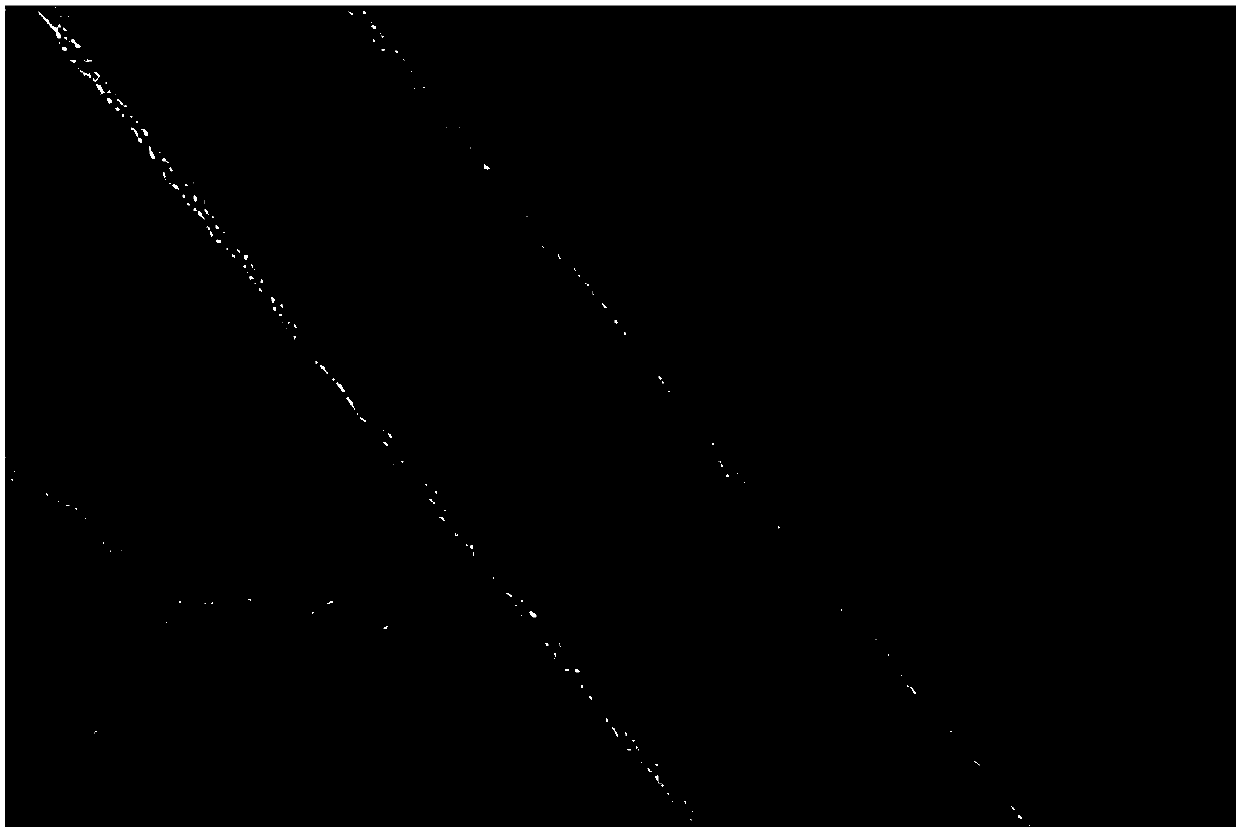

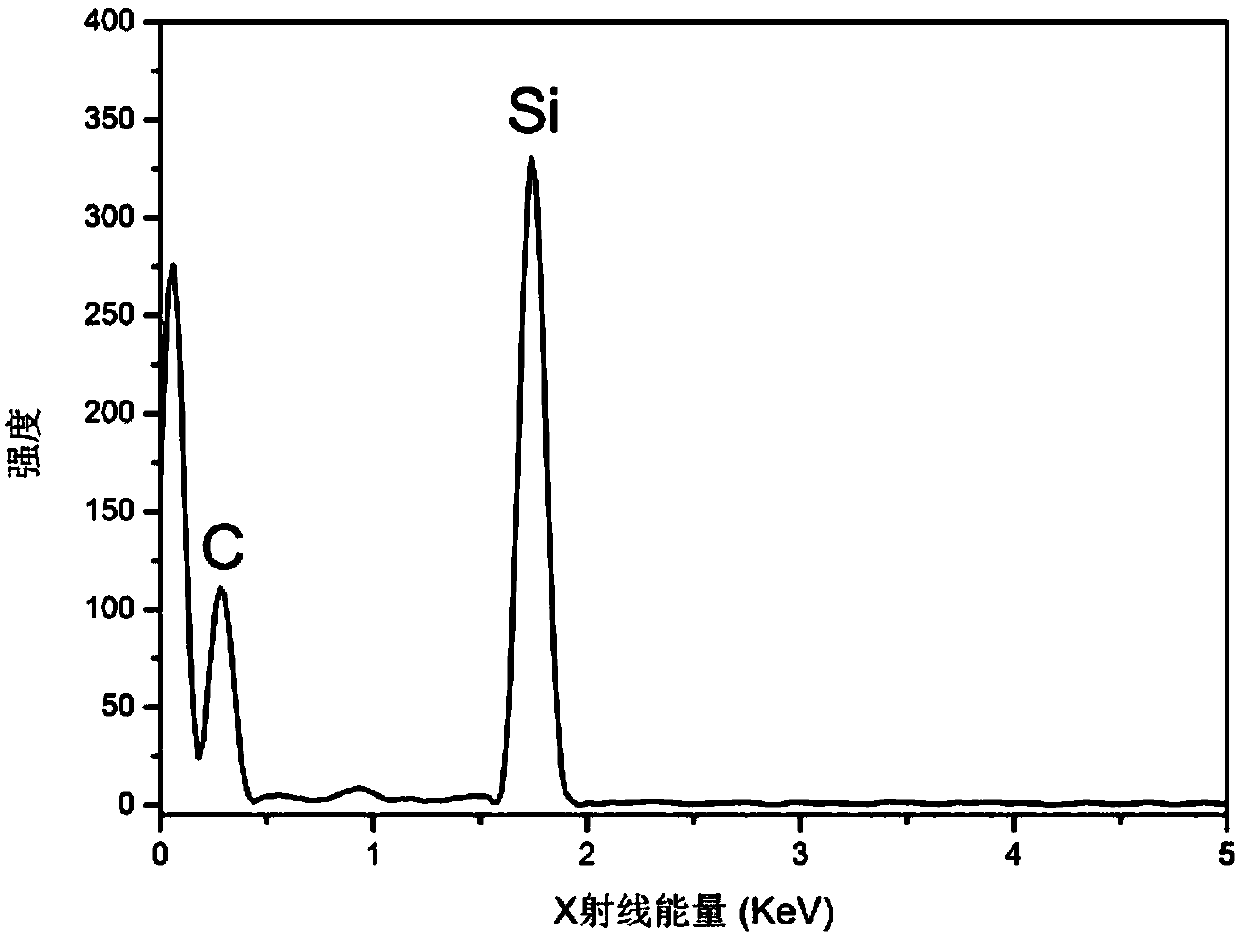

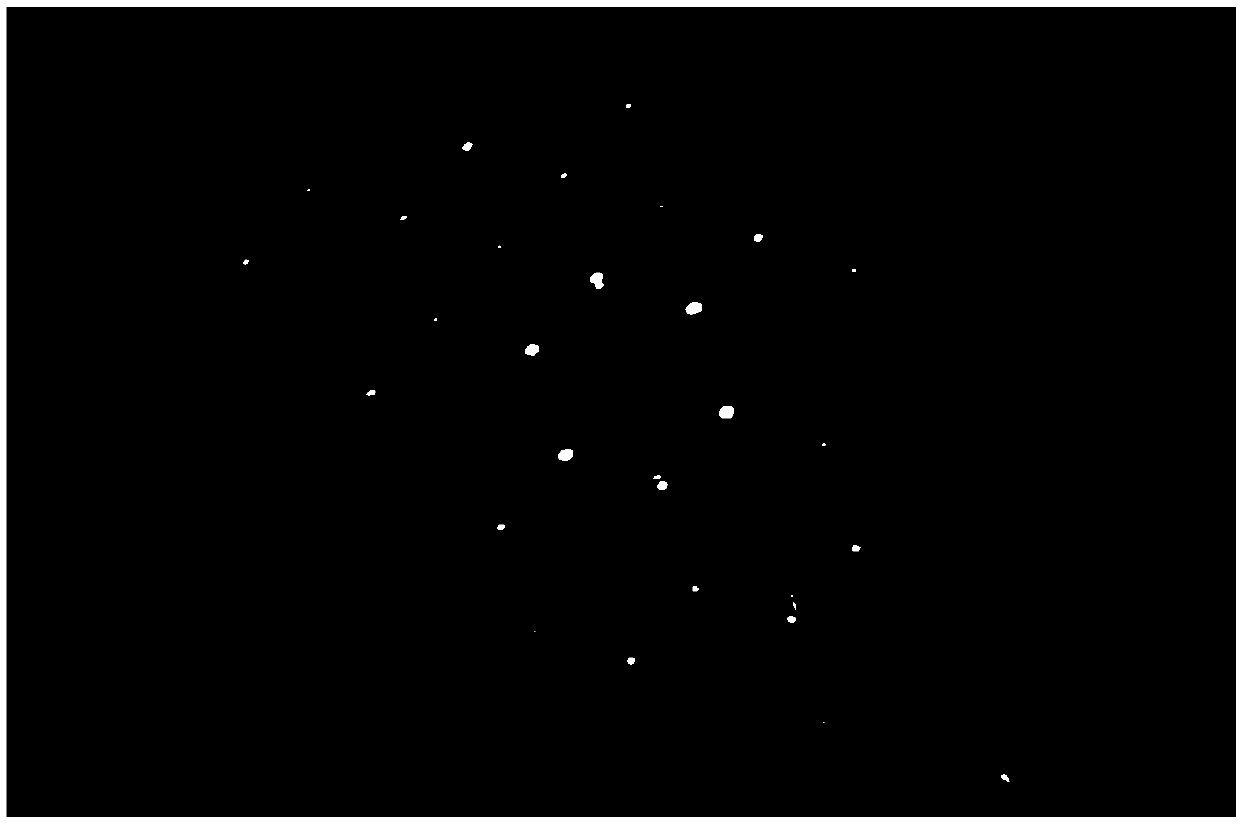

Embodiment 1

[0039] Weigh 60g sample of cutting waste mortar, crystal silicon cutting waste mortar is a by-product obtained during the cutting process of solar grade crystal silicon, mainly including silicon, silicon carbide, polyethylene glycol, water and iron. Among them, silicon is the loss during the cutting process of silicon ingots, silicon carbide is the abrasive, polyethylene glycol and water are used as the cutting fluid, and iron is the loss of the cutting wire. In terms of mass percentage, the raw materials in this example consist of 15-35wt% silicon, 30-60wt% silicon carbide, 10-60wt% polyethylene glycol, 5-10wt% water and 1-5wt% iron; Fully grind in a mortar for one hour, take 50g of ground waste and put it in a 1000ml beaker, add 500ml of absolute ethanol according to the mass ratio of 1:10, stir with a glass rod for 5 minutes, then magnetically stir for 40min. After the stirring is completed, the mixture is filtered, and the filter cake is taken and placed in a drying oven a...

Embodiment 2

[0049] Weigh 80g of cutting waste mortar sample (silicon 15-35wt%, silicon carbide 30-60wt%, polyethylene glycol 10-60wt%, water 5-10wt% and iron 1-5wt%) and place it in a mortar for full grinding For one hour, take 70g of ground waste and place it in a 1000ml beaker, add 700ml of absolute ethanol at a mass ratio of about 1:10, stir with a glass rod for 5 minutes, and then magnetically stir for 40 minutes. After the stirring is completed, the mixture is filtered, and the filter cake is taken and placed in a drying oven at 80° C. for drying for 3 hours, followed by grinding for 1 hour. Get the purified raw material m 1 = 62.78g. Alkali washing shows that the silicon content of the raw material powder is 47%.

[0050] Coir fiber is ultrasonically cleaned and dried. According to the Si content of the raw material powder and the carbonization rate of the sisal fiber, the raw material ratio is calculated and weighed. In this experiment, the weight ratio of raw material powder a...

Embodiment 3

[0053] Weigh 70g of the cutting waste mortar sample (silicon 15-35wt%, silicon carbide 30-60wt%, polyethylene glycol 10-60wt%, water 5-10wt%, and iron 1-5wt%) and place it in a mortar for full grinding For one hour, take 60g of ground waste and place it in a 1000ml beaker, add 600ml of absolute ethanol at a mass ratio of about 1:10, stir with a glass rod for 5 minutes, then magnetically stir for 40 minutes. After the stirring is completed, the mixture is filtered, and the filter cake is taken and placed in a drying oven at 80° C. for drying for 3 hours, followed by grinding for 1 hour. Get the purified raw material m 1 = 54.57 g. Alkali washing shows that the silicon content of the raw material powder is 44%.

[0054] The pineapple leaf plant fibers were ultrasonically cleaned and dried.

[0055] According to the Si content of the raw material powder and the carbonization rate of the pineapple leaf fiber, the raw material ratio is calculated and the ingredients are weighed....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com