Transportation fixing equipment for liquefied natural gas tank sets

A technology for liquefied natural gas tanks and fixed equipment, which is applied to mechanical equipment, container discharge methods, gas/liquid distribution and storage, etc., and can solve the problem of large distortion and deformation of the location, inconvenient maintenance and inspection, and high cylinder position. problem, to achieve the effect of long manufacturing time, high manufacturing cost and lower transportation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

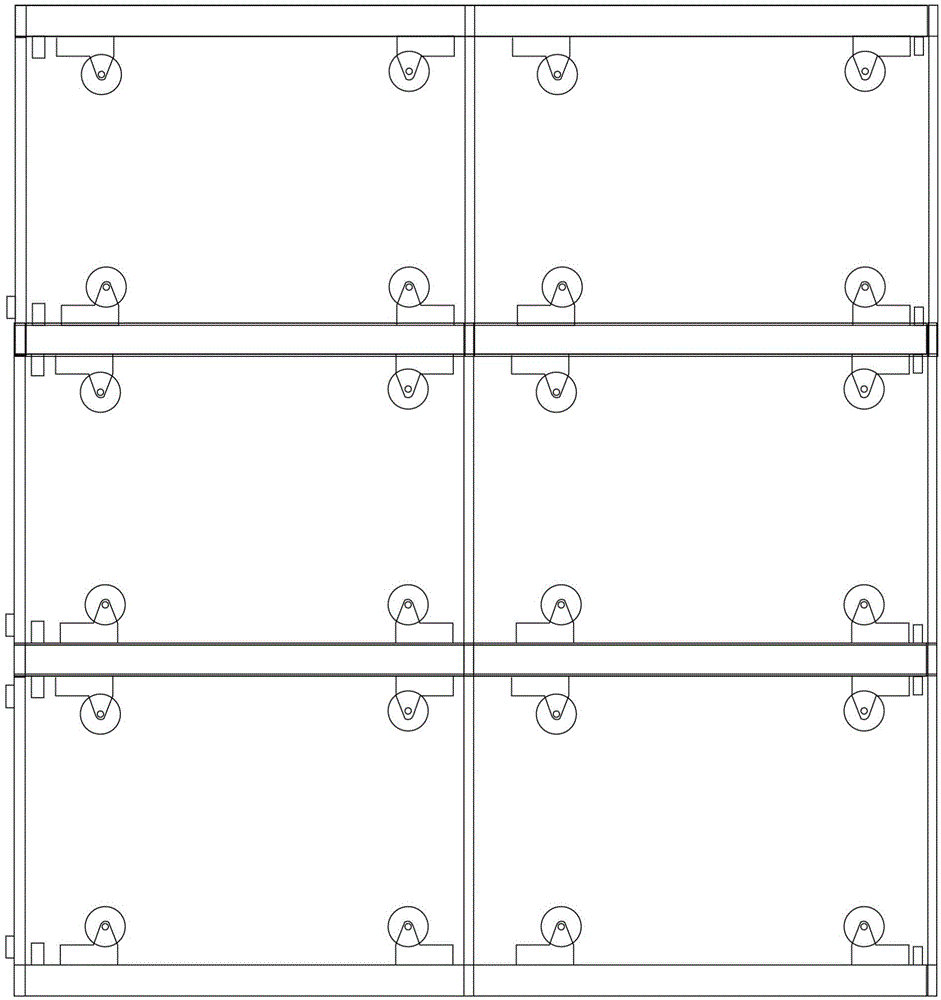

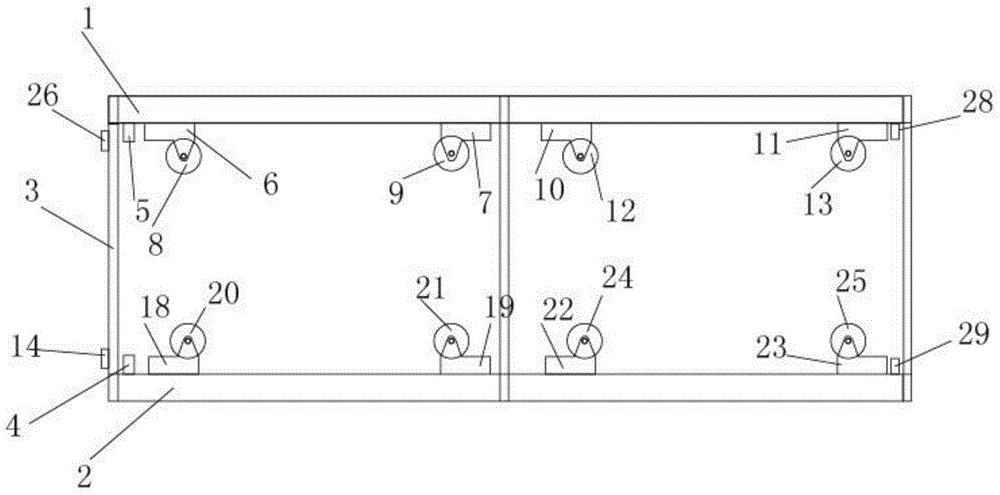

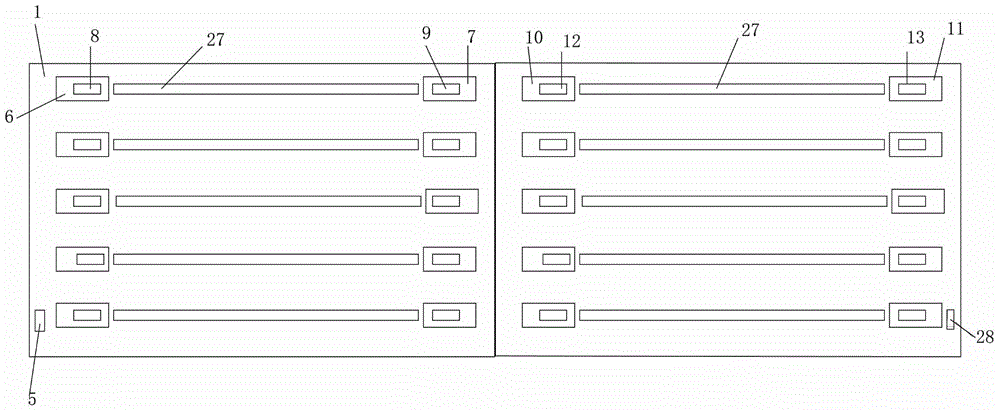

[0017] The technical solutions of the present invention will be further described below through specific examples.

[0018] Such as Figures 1 to 5 As shown in the figure: 1 is the upper base, 2 is the lower base, 3 is the supporting device, 4 is the second driving device, 5 is the first driving device, 6 is the first driving wheel supporting device, and 7 is the first driven wheel Supporting device, 8 is the first driving wheel, 9 is the first driven wheel, 10 is the second driving wheel supporting device, 11 is the second driven wheel supporting device, 12 is the second driving wheel, 13 is the second driven wheel, 14 15 is the first supporting member, 16 is the second supporting member, 17 is the anti-skid groove, 18 is the third driving wheel supporting device, 19 is the third driven wheel supporting device, 20 is the third driving wheel , 21 is the third driven wheel, 22 is the fourth driving wheel supporting device, 23 is the fourth driven wheel supporting device, 24 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com