Method for synthesizing porous structure based on energetic compound in-situ enhanced Ta/Si combustion

A technology of combustion synthesis and porous structure, applied in the direction of carbon compounds, chemical instruments and methods, metal silicides, etc., can solve the problems of low energy utilization rate, high production cost, complex process, etc., and achieve low energy utilization rate and energy supply The effect of long time and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Spherical Si powder with an average particle diameter of 100 nm and spherical Ta powder with an average particle diameter of 2 μm were weighed according to the masses shown in Table 1, respectively. The spherical Si powder was coated on the surface of the spherical Ta powder by electrostatic self-assembly method to obtain Ta@Si powder. Weigh polyvinylidene fluoride and hexanitrohexaazaisowurtzitane according to the mass shown in Table 1, add them to a beaker containing 50ml of a mixed solution of dimethylformamide and acetone, and ultrasonically dissolve the energetic complex , and adding Ta@Si powder to prepare a spray granulation slurry, and magnetic stirring at room temperature for 1-10 hours. Ta@Si@ECs microspheres with core-shell structure were prepared by spray drying device. The Ta@Si@ECs microspheres were loaded into a mold and pressed into a columnar billet with a cold pressing pressure of 2 MPa. Put the pressed billet into the combustion chamber, fill it wit...

Embodiment 2

[0061] Weighing according to Table 1, other with embodiment 1;

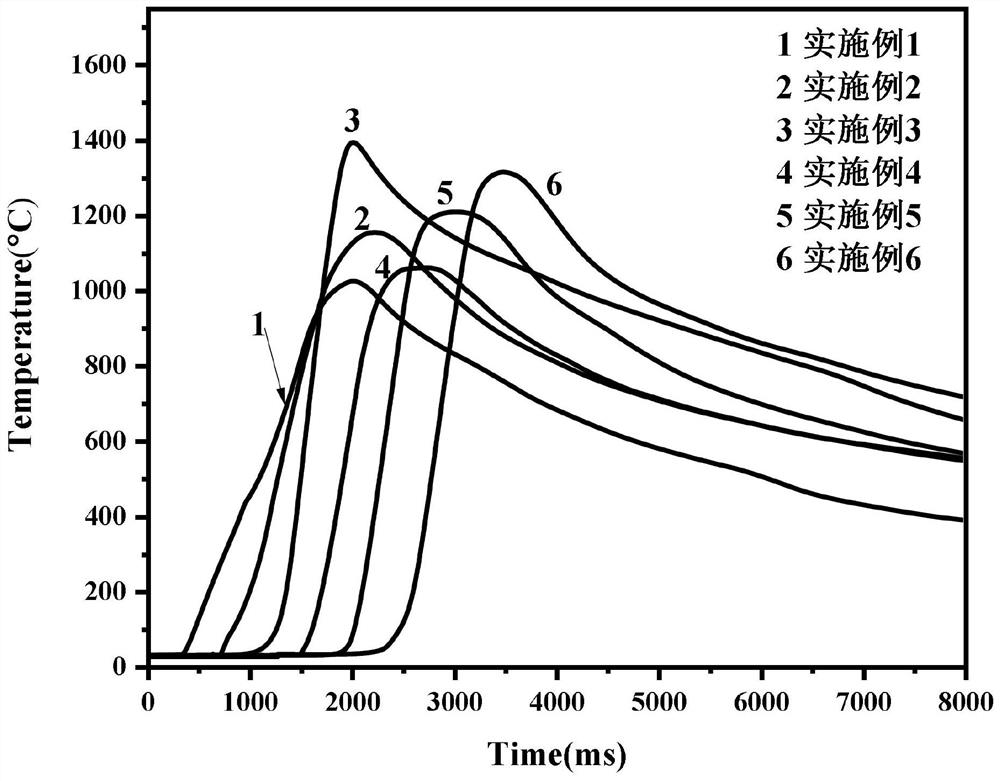

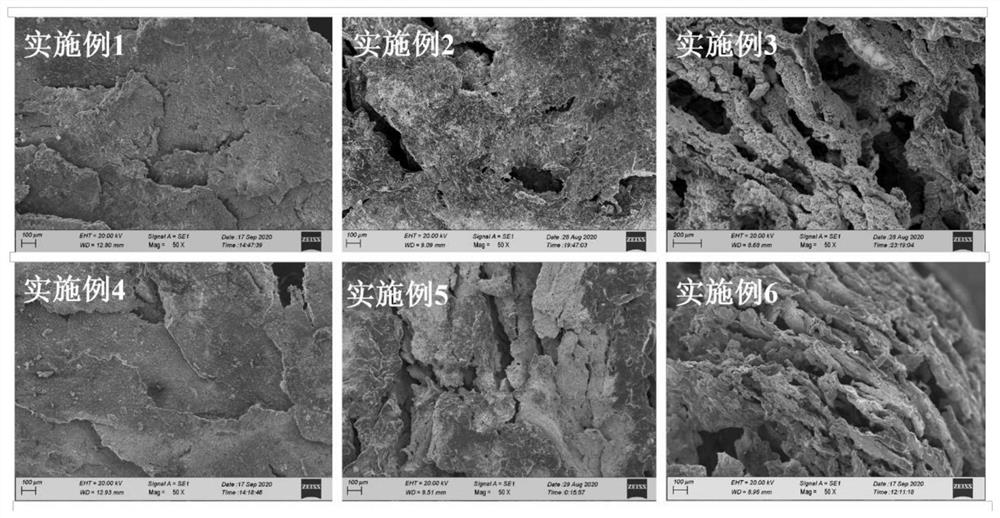

[0062] As can be seen from Table 2, the combustion velocity of embodiment 2 is close to embodiment 1; figure 2 Can find out that the highest combustion wave temperature of embodiment 2 is 1152 ℃; From image 3 It can be seen that the porosity of its combustion synthesis product obviously improves compared with Example 1, and the content of TaC increases compared with Example 1 ( Figure 4 ).

Embodiment 3

[0064] Weighing according to Table 1, other with embodiment 1;

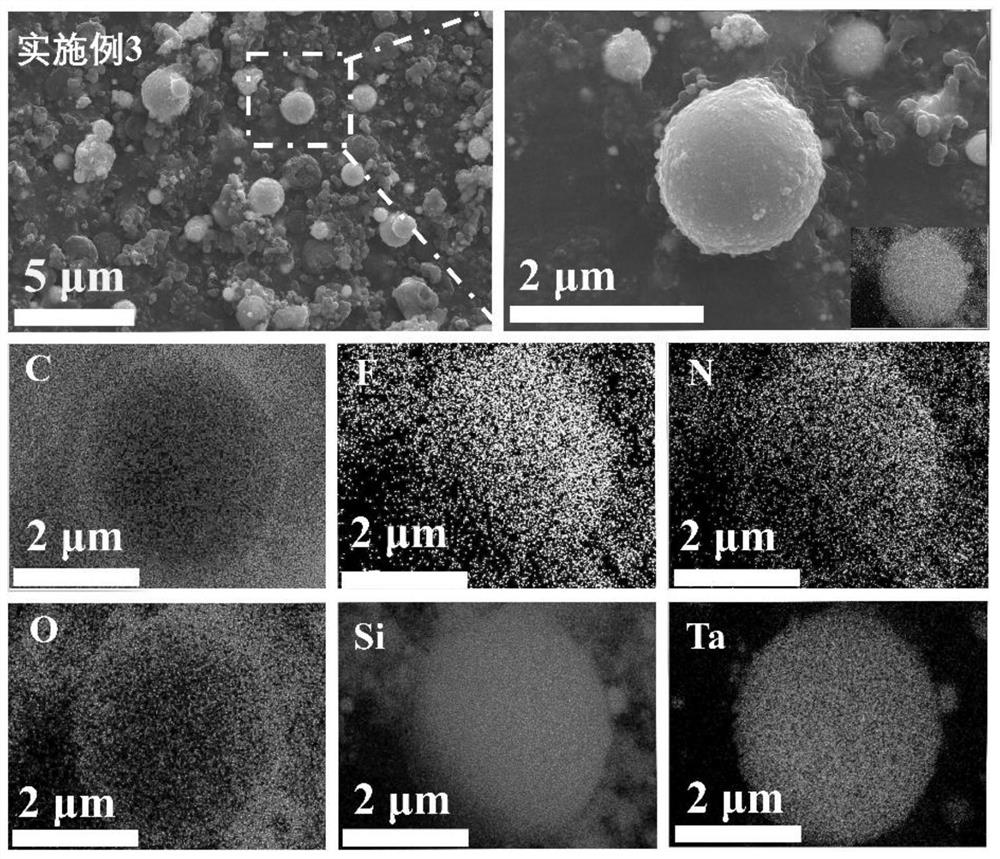

[0065] From figure 1 It can be seen that there are four components of polyvinylidene fluoride, hexanitrohexaazaisowurtzitane, μ-Ta, and n-Si in Example 3; as can be seen from Table 2, the burning speed of Example 3 is 5.1mm / s; from figure 2 It can be seen that the highest combustion wave temperature of embodiment 3 is 1392 ℃, compared with embodiments 1 and 2, the combustion speed has improved by 1.6 times; from image 3 It can be seen that the combustion synthesis product has a large number of pores, and its porosity is greatly improved. At the same time, new tantalum nitrides and oxides appear in the product. For details, see Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com