A kind of graphene-based microcrystalline jade decoration material and preparation method thereof

A technology of microcrystalline jade and decorative materials, which is applied in glass pressing, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of high cost, limited improvement of mechanical properties of graphite powder, and insufficient utilization, so as to achieve excellent effect and increase cost. Nuclear effect, defect reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

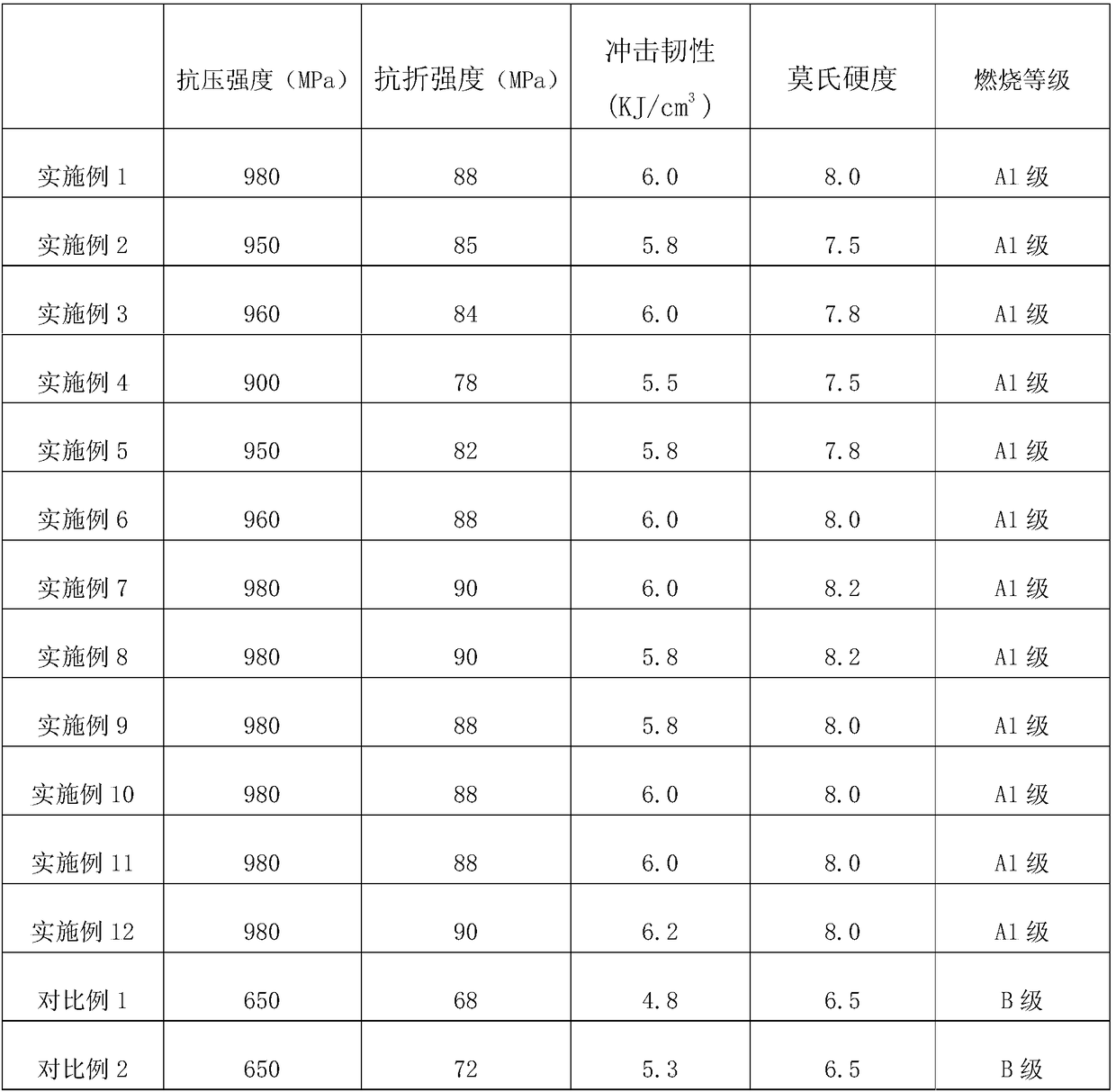

Examples

Embodiment 1

[0036] A graphene-based microcrystalline jade decorative material is made of the following components by weight percentage:

[0037] 50 parts of stone tailings, 50 parts of silicon dioxide, 10 parts of graphene, 2 parts of silicon carbide whiskers, 5 parts of lithium feldspar, 5 parts of albite feldspar, 10 parts of alumina, 10 parts of high-temperature co-solvent, 20 parts of calcium carbonate 2 parts of zinc oxide, 2 parts of barium carbonate, 2 parts of boron oxide, 5 parts of zirconia, 5 parts of sodium carbonate, 4 parts of titanium dioxide, 5 parts of yttrium trioxide, 3 parts of antimony trioxide, 2 parts of debonding agent , 2 parts of stabilizer, 2 parts of inorganic pigment.

[0038] Wherein, the stone tailings are granite tailings; the high-temperature flux is calcined talc; and the stabilizer is yttrium oxide.

[0039] A preparation method of graphene-based microcrystalline jade decorative material, comprising the following steps:

[0040] S1. Raw material prepar...

Embodiment 2

[0045] A graphene-based microcrystalline jade decorative material is made of the following components by weight percentage:

[0046] 60 parts of stone tailings, 30 parts of silicon dioxide, 5 parts of graphene, 3 parts of silicon carbide whiskers, 8 parts of lithium feldspar, 4 parts of albite, 10 parts of high-temperature co-solvent, 20 parts of calcium carbonate, 2 parts of zinc oxide 5 parts of zirconia, 2 parts of barium carbonate, 3 parts of boron oxide, 5 parts of sodium carbonate, 6 parts of titanium dioxide, 4 parts of yttrium trioxide, 2 parts of antimony trioxide, 3 parts of debonding agent, 2 parts of stabilizer .

[0047] Wherein, the stone tailings are quartz tailings and diabase tailings. The high temperature flux is calcined talc and fluorite; the stabilizer is yttrium oxide and cerium oxide.

[0048] The preparation method is the same as in Example 1.

Embodiment 3

[0050] A graphene-based microcrystalline jade decorative material is made of the following components by weight percentage:

[0051] 40 parts of stone tailings, 60 parts of silicon dioxide, 8 parts of graphene, 3 parts of silicon carbide whiskers, 2 parts of lithium feldspar, 2 parts of albite feldspar, 10 parts of aluminum hydroxide, 10 parts of high-temperature co-solvent, calcium carbonate 30 parts, 3 parts of zirconia, 5 parts of boron oxide, 3 parts of sodium carbonate, 5 parts of titanium dioxide, 5 parts of yttrium trioxide, 3 parts of antimony trioxide, 3 parts of debonding agent, 3 parts of stabilizer, inorganic pigment 2 servings.

[0052] Wherein, the stone tailings are feldspar tailings. The high temperature flux is calcined talc and raw talc; the stabilizer is cerium oxide.

[0053] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com