Preparation method of nickel-based copper-coated silicon carbide laser cladding layer

A technology of copper-clad silicon carbide and laser cladding, which is applied in the direction of coating, etc., to achieve the effect of weakening the direct effect, improving the service life and avoiding burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

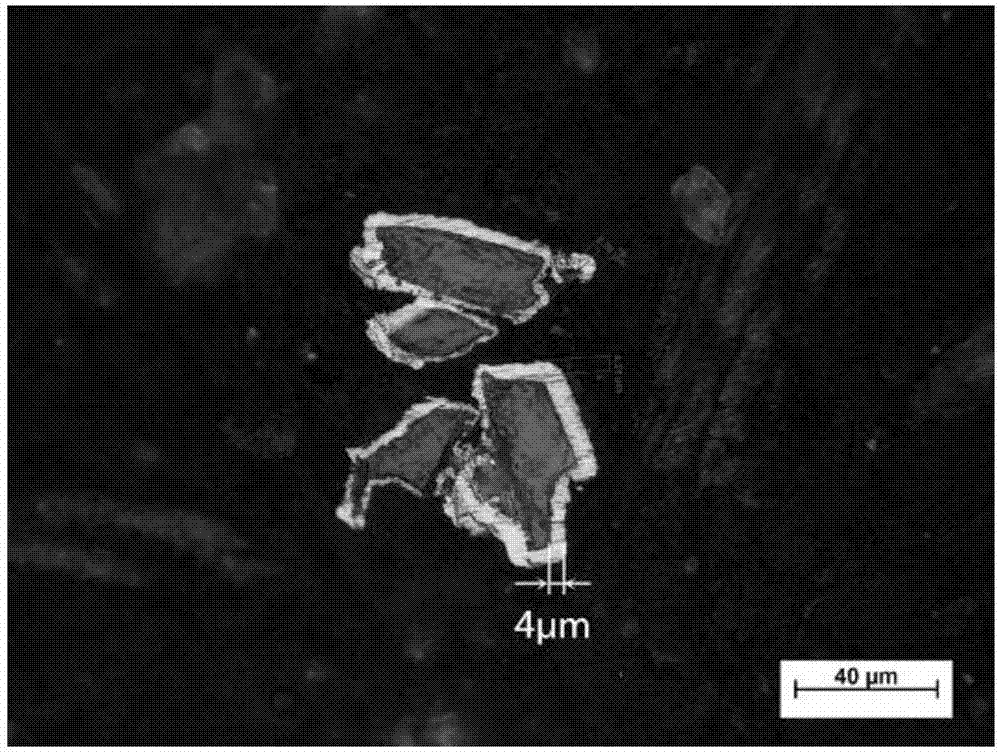

Image

Examples

Embodiment 1

[0032] A preparation method of a nickel-based copper-clad silicon carbide laser cladding layer, comprising the steps of:

[0033] (1) First purify the SiC powder, put the SiC powder with a particle size of 300 mesh to 350 mesh in a crucible furnace at 800 ° C for 2 hours to remove free carbon, metal and other organic impurities mixed in the SiC powder; then SiC Powder cleaning, ultrasonic cleaning of SiC powder with deionized water, and then degreasing of SiC powder with 10wt% NaOH, and then soaking in 10wt% dilute hydrochloric acid to neutralize the NaOH in the previous step, and finally using absolute ethanol to degrease the SiC powder. Perform ultrasonic cleaning until the liquid is clear after cleaning; then roughen the SiC powder, use 5wt% HF solution to soak the SiC powder for 5 minutes under ultrasonic conditions to improve the surface roughness of SiC, and use a Clean the powder with ionized water; then sensitize the SiC powder, put the SiC powder in a mixed solution o...

Embodiment 2

[0041] A preparation method of a nickel-based copper-clad silicon carbide laser cladding layer, comprising the steps of:

[0042] (1) First purify the SiC powder, put the SiC powder with a particle size of 300 mesh to 350 mesh in a crucible furnace at 700 ° C for 2 hours to remove free carbon, metal and other organic impurities mixed in the SiC powder. Then clean the SiC powder, ultrasonically clean the SiC powder with deionized water, then use 10wt% NaOH to degrease the SiC powder, then soak in 10wt% dilute hydrochloric acid to neutralize the NaOH in the previous step, and finally use anhydrous Ethanol was used to ultrasonically clean the SiC until the liquid was clear after cleaning. Then, roughen the SiC powder, use 5wt% HF solution to soak the SiC powder for 5 minutes under ultrasonic conditions to improve the surface roughness of SiC to strengthen the effect of the subsequent steps, and use deionized water after roughening. Clean up. Subsequently, the SiC powder was sen...

Embodiment 3

[0050] A preparation method of a nickel-based copper-clad silicon carbide laser cladding layer, comprising the steps of:

[0051] (1) First purify the SiC powder, put the SiC powder with a particle size of 300 mesh to 350 mesh in a crucible furnace at 900 ° C for 2 hours to remove free carbon, metal and other organic impurities mixed in the SiC powder. Then clean the SiC powder, ultrasonically clean the SiC powder with deionized water, then use 10wt% NaOH to degrease the SiC powder, then soak in 10wt% dilute hydrochloric acid to neutralize the NaOH in the previous step, and finally use anhydrous Ethanol was used to ultrasonically clean the SiC until the liquid was clear after cleaning. Then, roughen the SiC powder, use 5wt% HF solution to soak the SiC powder for 5 minutes under ultrasonic conditions to improve the surface roughness of SiC to strengthen the effect of the subsequent steps, and use deionized water after roughening. Clean up. Subsequently, the SiC powder was sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com