STF (shear thickening fluid) as well as preparation method and application thereof

A liquid, three-dimensional technology, applied in the field of shear thickening liquid and its preparation, can solve the problems of weak friction, inability to effectively absorb and diffuse the high-speed impact energy of bullets, weak ballistic impact performance, etc., and achieve large fracture work and fracture Low elongation, strong energy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a three-dimensional angle interlocking bulletproof fabric, comprising the following steps:

[0038] 1) Dry the three-dimensional bulletproof fabric at 50°C for 2 hours, cool and set aside;

[0039] 2) mixing shear-thickening liquid and absolute ethanol by mass ratio of 1:1.5 at 25 DEG C of ultrasonic vibrations for 30min to obtain diluent, for subsequent use;

[0040] 3) Immerse the cooled three-dimensional bulletproof fabric in a diluent with a temperature of 25°C, and ultrasonically vibrate for 5 minutes, so that the shear-thickening liquid is uniformly dispersed in the fabric. ;

[0041] 4) Dry the impregnated three-dimensional bulletproof fabric at 75°C for 13 minutes, and then cool to obtain a three-dimensional angle interlocking bulletproof fabric;

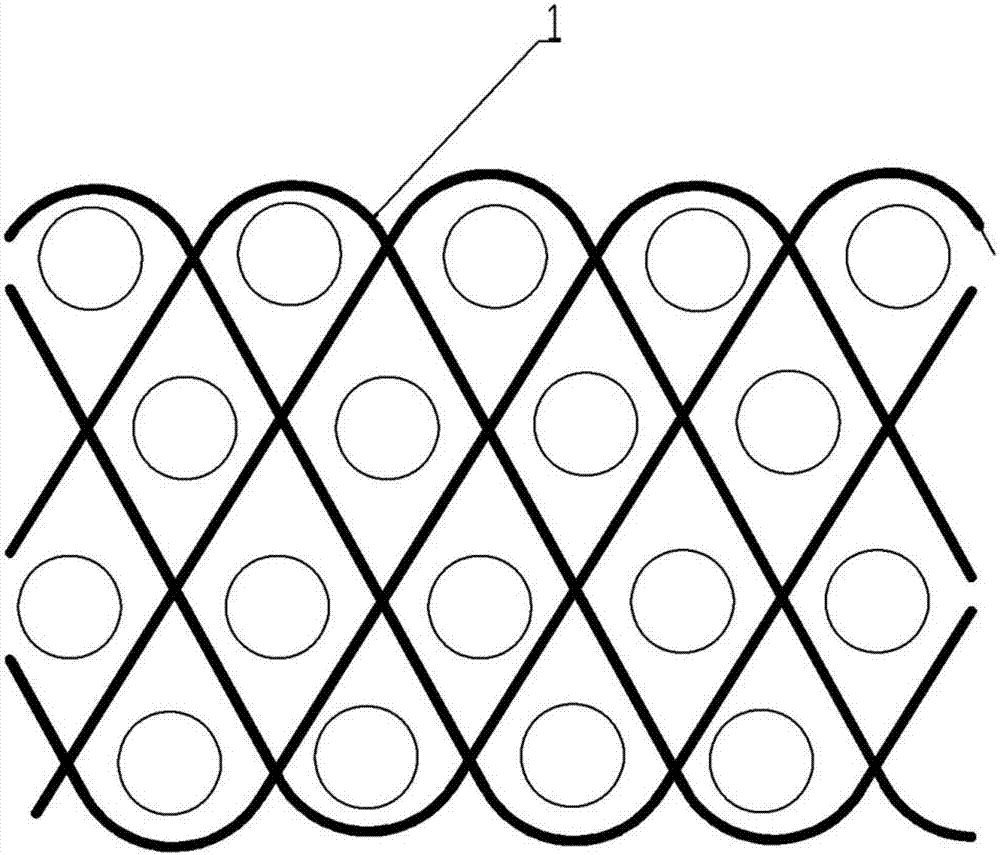

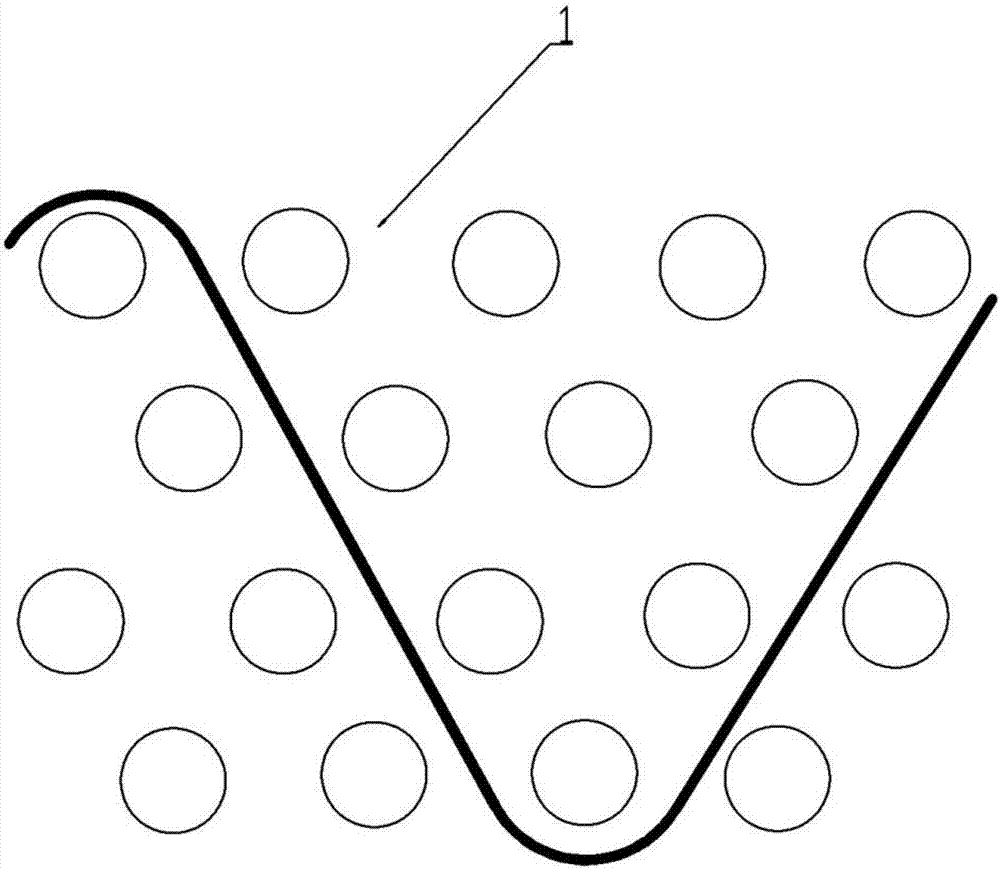

[0042] The three-dimensional bulletproof fabric includes 4 layers of yarns formed by interweaving aramid warp yarns and aramid weft yarns. The multi-layer yarn layers are bound by the binding...

Embodiment 2

[0048] A preparation method of a three-dimensional angle interlocking bulletproof fabric, comprising the following steps:

[0049] 1) Dry the three-dimensional bulletproof fabric at 50°C for 2 hours, cool and set aside;

[0050]2) mixing shear-thickening liquid and absolute ethanol by mass ratio of 1:1.5 at 25 DEG C of ultrasonic vibrations for 30min to obtain diluent, for subsequent use;

[0051] 3) Immerse the cooled three-dimensional bulletproof fabric in a diluent with a temperature of 25°C, and ultrasonically vibrate for 4min, so that the shear-thickening liquid is uniformly dispersed in the fabric;

[0052] 4) Dry the impregnated three-dimensional bulletproof fabric at 75°C for 13 minutes, and then cool to obtain a three-dimensional angle interlocking bulletproof fabric;

[0053] The three-dimensional bulletproof fabric includes 4 layers of yarns formed by interweaving aramid warp yarns and aramid weft yarns. The multi-layer yarn layers are bound by the binding yarns ob...

Embodiment 3

[0059] A preparation method of a three-dimensional angle interlocking bulletproof fabric, comprising the following steps:

[0060] 1) Dry the three-dimensional bulletproof fabric at 50°C for 2 hours, cool and set aside;

[0061] 2) mixing shear-thickening liquid and absolute ethanol by mass ratio of 1:1.5 at 25 DEG C of ultrasonic vibrations for 30min to obtain diluent, for subsequent use;

[0062] 3) Immerse the cooled three-dimensional bulletproof fabric in a diluent with a temperature of 25°C, and ultrasonically vibrate for 4min, so that the shear-thickening liquid is uniformly dispersed in the fabric;

[0063] 4) Dry the impregnated three-dimensional bulletproof fabric at 75°C for 13 minutes, and then cool to obtain a three-dimensional angle interlocking bulletproof fabric;

[0064] The three-dimensional bulletproof fabric includes 4 layers of yarns formed by interweaving aramid warp yarns and aramid weft yarns. The multi-layer yarn layers are bound by the binding yarns o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com