Formation method of fin-type field-effect transistor

A technology of fin field effect transistors and fins, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of improving electrical performance, avoiding etching damage, and good morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It can be seen from the background art that the electrical performance of the fin field effect transistor formed in the prior art needs to be improved.

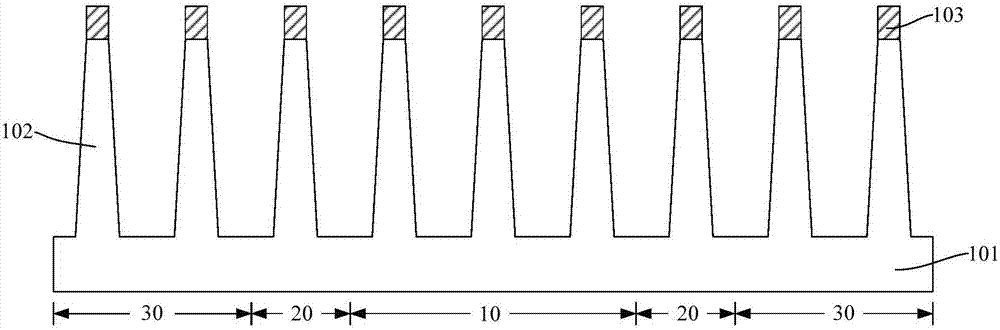

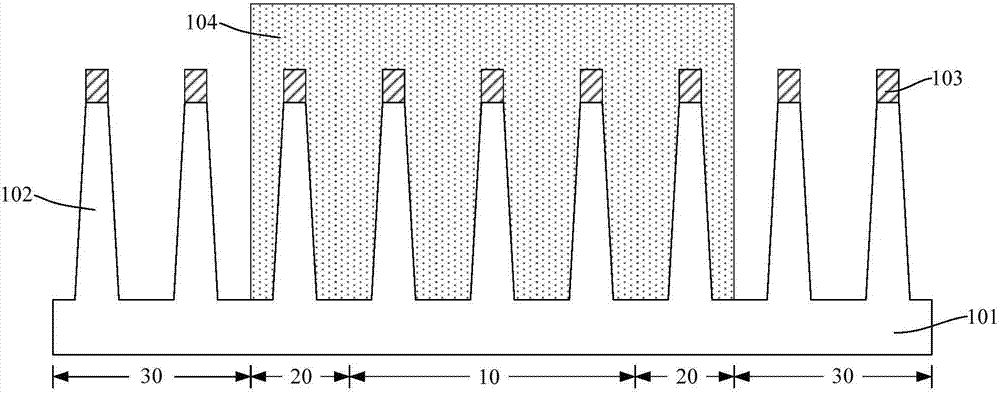

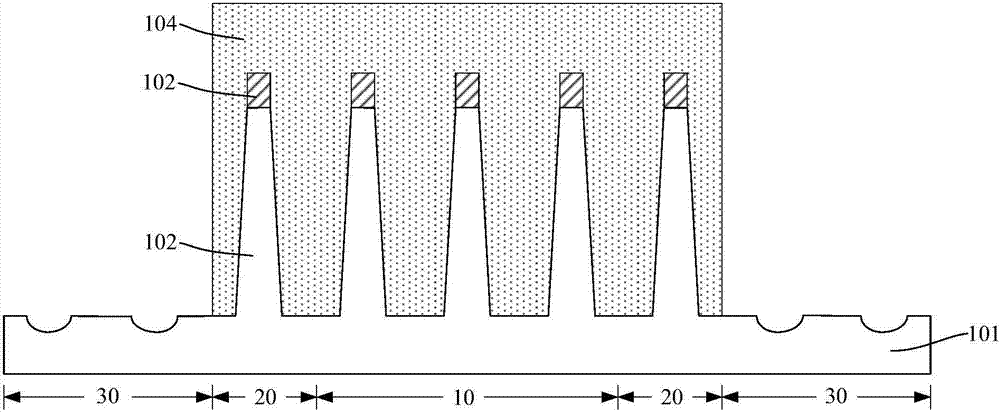

[0032] In the FinFET, the base usually includes an active area and an edge area adjacent to the active area, wherein the active area has a fin formed on the base, while the edge area has no fin on the base. Generally, the process steps of forming fins on the base of the active area include: firstly forming discrete fins on the base of the active area and the base of the edge area; then, forming a pattern covering the fins on the base of the active area layer; using the graphic layer as a mask, etching and removing the fins located on the base of the edge area; removing the graphic layer.

[0033] However, in the FinFET formed by the above method, the fins on the base of the active area will be damaged, resulting in changes in the shape and size of the fins, and the damage to the fins on the base of the active area clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com