Quick dehydration device for producing citrate plasticizers

A rapid dehydration and plasticizer technology, applied in chemical instruments and methods, evaporator accessories, evaporation, etc., can solve the problems of low dehydration efficiency, long distillation time, and entry of oil-soluble impurities, so as to improve contact efficiency and increase contact Effect, effect of improving dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

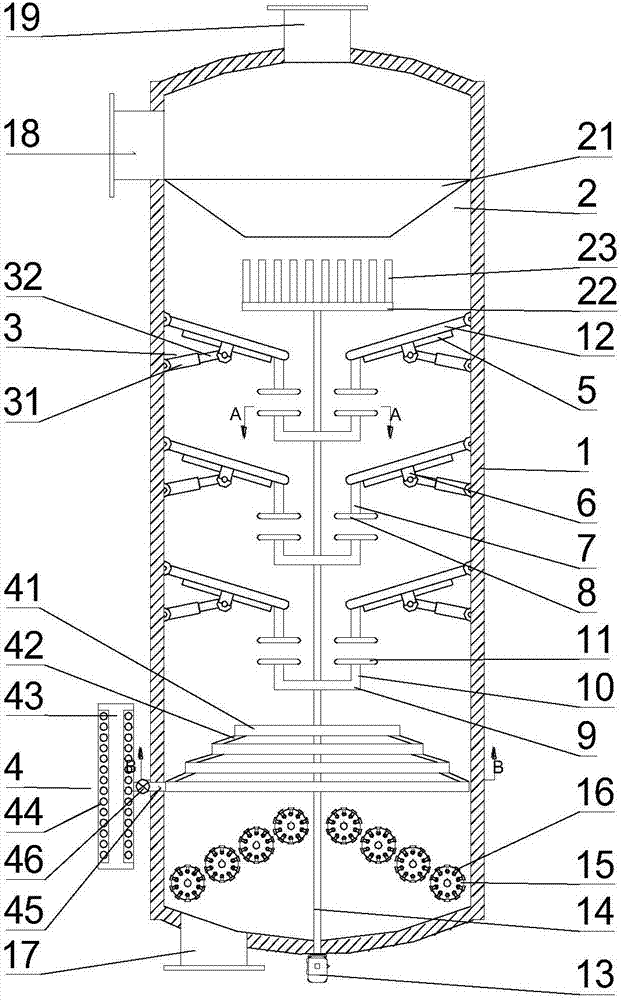

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

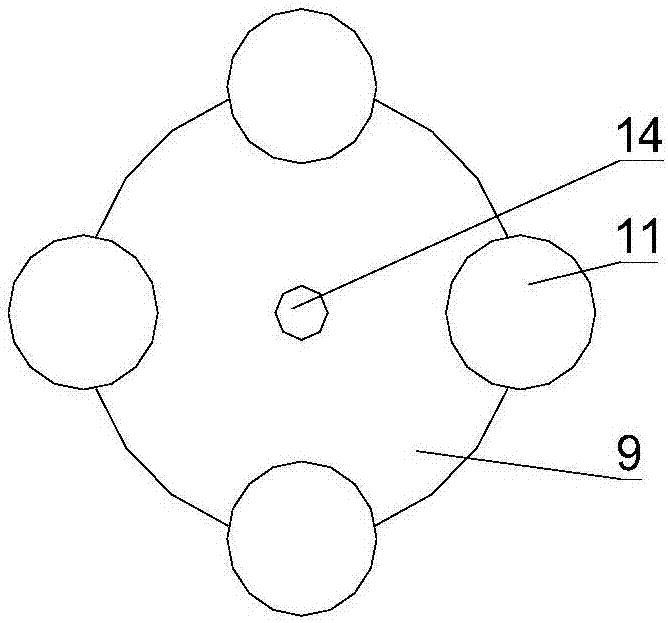

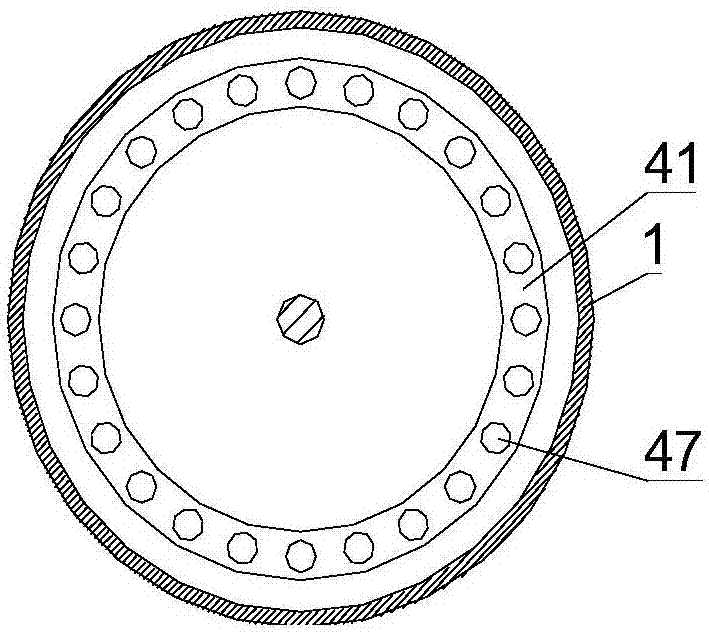

[0019] see Figure 1-4 A fast dehydration device for the production of citric acid lipid plasticizers, comprising a tank body 1, a rotating wheel 15, a hopper 16, an air blowing device, a deflector 12, a slide rail 5, a sliding sleeve 6, an elastic telescopic device 3, Turning plate 9, first magnet 8, second magnet 11 and dispersing device 2, the internal upper side of described tank body 1 is equipped with dispersing device 2, and several groups of deflectors 12 are arranged in the middle of tank body 1, several groups The deflectors 12 are vertically arranged at equal intervals, and each group of deflectors 12 includes some deflectors 12 arranged along the circumferential inner wall of the tank body 1, and the deflectors 12 are close to the inside end of the tank body 1 and the tank body The inner walls of 1 are hinged, the bottom of deflector 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com