A kind of packaging film making equipment

A packaging film and equipment technology, applied in the field of self-adhesive processing devices, can solve the problems of easy tearing of self-adhesive films, and achieve the effects of improving cutting ability, large circumferential rotational moment, and increasing punching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

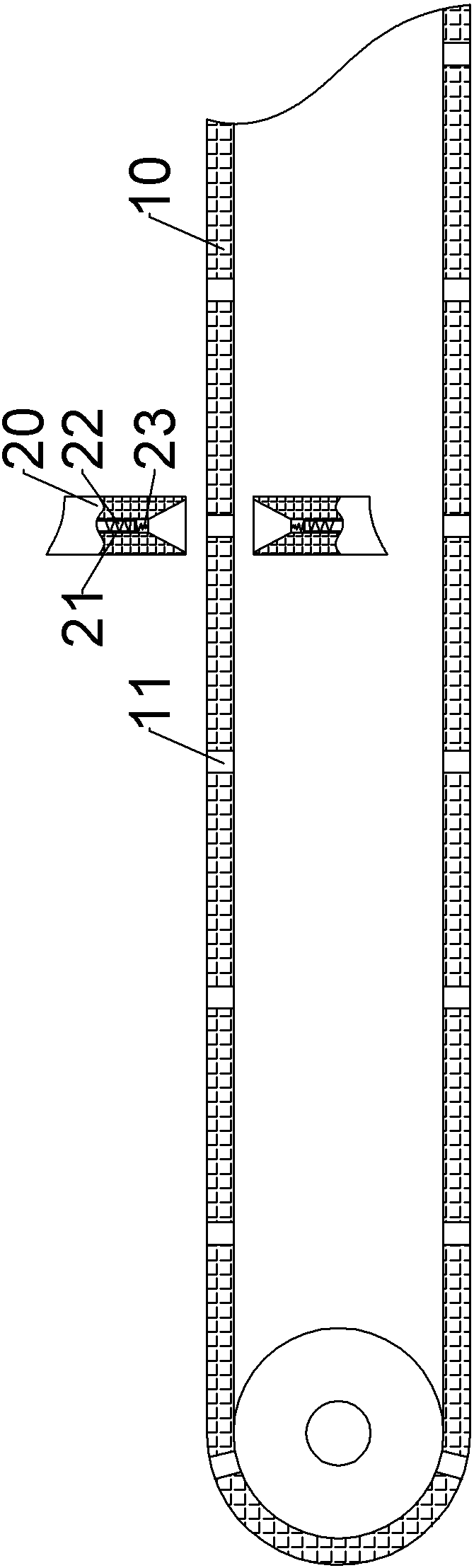

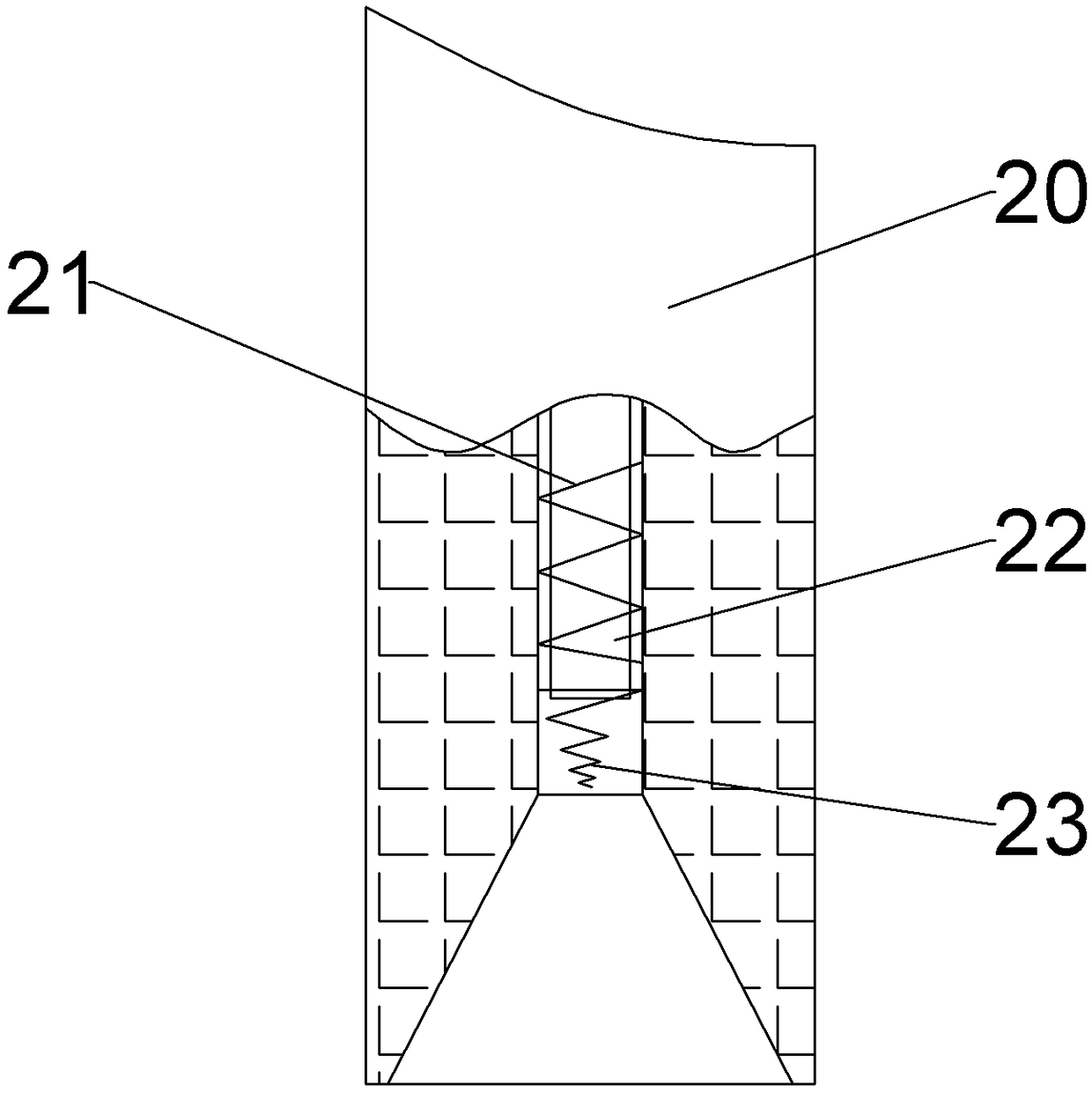

[0021] The reference numerals in the drawings of the description include: conveyor belt body 10 , through hole 11 , upper drive unit 20 , helical coil 21 , iron core 22 , buffer spring 23 , flying knife 30 , and spiral groove 31 .

[0022] The embodiment is basically as figure 1 Shown: the packaging film production equipment in this program includes a frame on which a conveyor belt, a flying knife 30 and a drive unit group for driving the flying knife 30 are fixed, and the conveyor belt includes a conveyor belt body 10 and drives its rotation Conveying rollers, the drive unit group includes an upper drive unit 20 and a lower drive unit that are relatively arranged above and below the conveyor belt body 10, and the upper drive unit 20 has the same structure as the lower drive unit, as image 3 As shown, the upper drive unit 20 includes a drive sleeve, an iron core 22 loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com