A kind of cold heading steel and its manufacturing process

A manufacturing process and technology for cold heading steel, applied in the field of cold heading steel and its manufacturing process, can solve the problems of increased Si in molten steel, unstable pourability, and direct flow affecting product quality and production, so as to achieve good pourability, It is not easy to nodulate the nozzle, and the effect of improving the cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

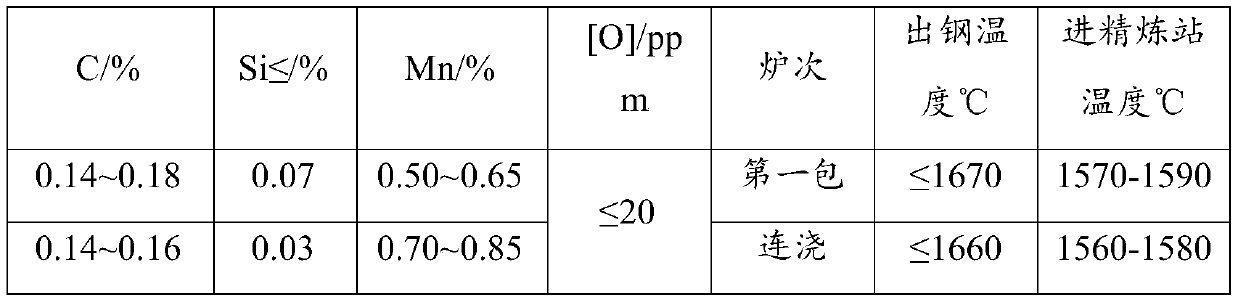

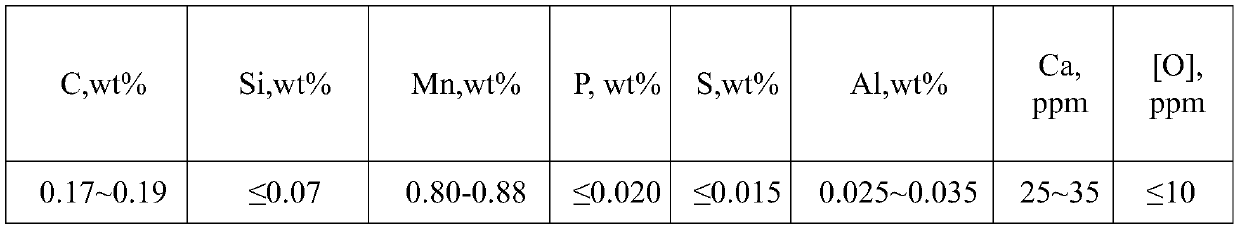

[0060] This embodiment provides a manufacturing process of cold heading steel, which includes the following steps.

[0061] S1, smelting steps

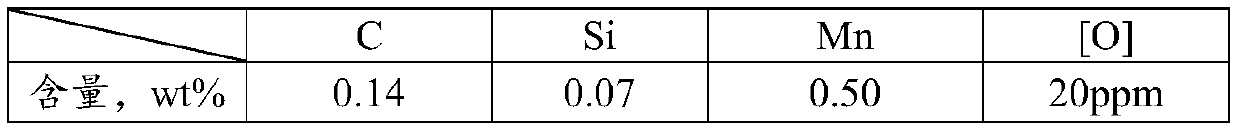

[0062] Using molten iron as raw material, the composition of molten iron is Si: 0.30wt%, Mn: 0.30wt%, P≤0.120wt%, S≤0.050wt%, Cr≤0.20wt%, Ni≤0.10wt%, Cu≤0.15wt% , As≤0.015wt%. The temperature of molten iron is 1250°C. According to the loading capacity of 91.5t, it enters the 100t converter for smelting.

[0063] The deoxidation alloying operation is carried out during the tapping process, and the Al-Mn-Fe alloy is put into the ladle for deoxidation. The addition amount of the first batch of continuous casting is 4kg / ton of steel, and the addition amount of subsequent continuous casting batches is 4.5kg / ton For steel, the lack of Mn is made up with medium carbon ferromanganese, and 50kg steel core aluminum is added to each furnace of steel for final deoxidation. Add synthetic slag (active lime + fluorite) 300kg / furnace during tappi...

Embodiment 2

[0077] This embodiment provides a manufacturing process of cold heading steel, which includes the following steps.

[0078] S1, smelting steps

[0079] Using molten iron and some scrap steel as raw materials, the composition of molten iron is Si: 0.50wt%, Mn: 0.50wt%, P≤0.120wt%, S≤0.050wt%, Cr≤0.20wt%, Ni≤0.10wt%, Cu≤ 0.15wt%, As≤0.015wt%. The temperature of molten iron is 1250°C. According to the loading capacity of 92t, it enters the 100t converter for smelting.

[0080] The deoxidation alloying operation is carried out during the tapping process, and the Al-Mn-Fe alloy is put into the ladle for deoxidation. The addition amount of the first batch of continuous casting is 4kg / ton of steel, and the addition amount of subsequent continuous casting batches is 4.5kg / ton For steel, the lack of Mn is made up with medium carbon ferromanganese, and 50kg steel core aluminum is added to each furnace of steel for final deoxidation. Add synthetic slag (active lime + fluorite) 300kg / ...

Embodiment 3

[0094] This embodiment provides a manufacturing process of cold heading steel, which includes the following steps.

[0095] S1, smelting steps

[0096] Using molten iron and some scrap steel as raw materials, the composition of molten iron is Si: 0.80wt%, Mn: 0.80wt%, P≤0.120wt%, S≤0.050wt%, Cr≤0.20wt%, Ni≤0.10wt%, Cu≤ 0.15wt%, As≤0.015wt%. The temperature of molten iron is 1250°C. According to the loading capacity of 92.5t, it enters the 100t converter for smelting.

[0097]The deoxidation alloying operation is carried out during the tapping process, and the Al-Mn-Fe alloy is put into the ladle for deoxidation. The addition amount of the first batch of continuous casting is 4kg / ton of steel, and the addition amount of subsequent continuous casting batches is 4.5kg / ton For steel, the lack of Mn is made up with medium carbon ferromanganese, and 50kg steel core aluminum is added to each furnace of steel for final deoxidation. Add synthetic slag (active lime + fluorite) 300kg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com