Adsorbing material with water-induced shape memory function, and preparation method and application thereof

A technology of adsorption material and functional composite material, applied in the field of adsorption material with water-induced shape memory function and its preparation, can solve the problems of loss of shape memory function, application limitation, slow recovery rate, etc., achieve excellent shape memory function, promote Degradation, the effect of improving adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A kind of preparation method of the adsorption material with water-induced shape memory function of the present invention, comprises the following steps:

[0028] 1) Preparation of shape memory functional composite material matrix: 10 to 40 parts of functional polymer materials containing amino functional groups and 10 to 25 parts of water-soluble polymers containing polyhydroxyl / carboxyl / amino groups are dissolved in 10 to 1000 g of water, and at 20°C to 80°C, the stirring speed is 40 to 400r / min, blending and stirring for 0.1 to 12 hours to obtain the shape memory functional composite material matrix A;

[0029] 2) Culture of microbial base: mix 0.5-10 parts of microorganisms and 0.01-10 parts of nutrient solution, stir evenly at 20°C-50°C to obtain microbial culture medium B; microorganisms are lactic acid bacteria, Escherichia coli, butyric acid bacteria, and spores Bacillus, yeast, lactobacillus, bifidobacterium, actinomycetes, chlorella in one or more mixed bacter...

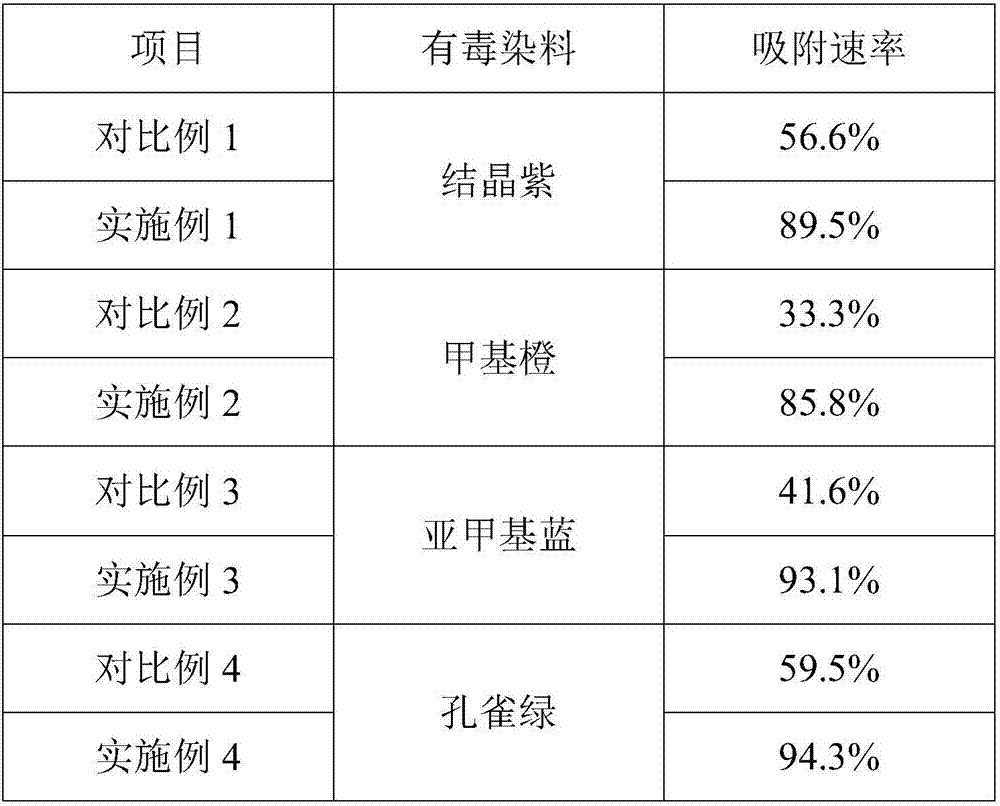

Embodiment 1

[0034] A preparation method of an adsorption material with shape memory function, comprising the steps of:

[0035] 1) Preparation of the shape memory functional composite material matrix: Dissolve 10 parts of polyethyleneimine and 10 parts of polyvinyl alcohol in 100 parts of deionized water in parts by mass; at 80°C, the stirring speed is 400r / min, Blending and stirring for 12 hours to obtain a shape memory functional composite material matrix A;

[0036] 2) Microbial base culture: mix 0.5 part of Bacillus and 0.01 part of peptone, stir evenly at 50°C to obtain microbial medium B;

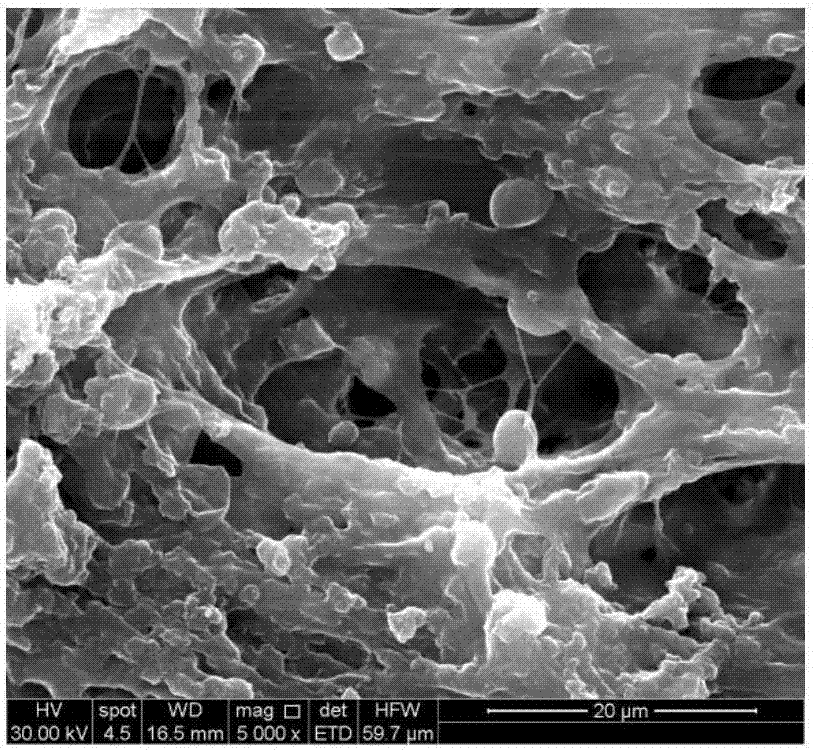

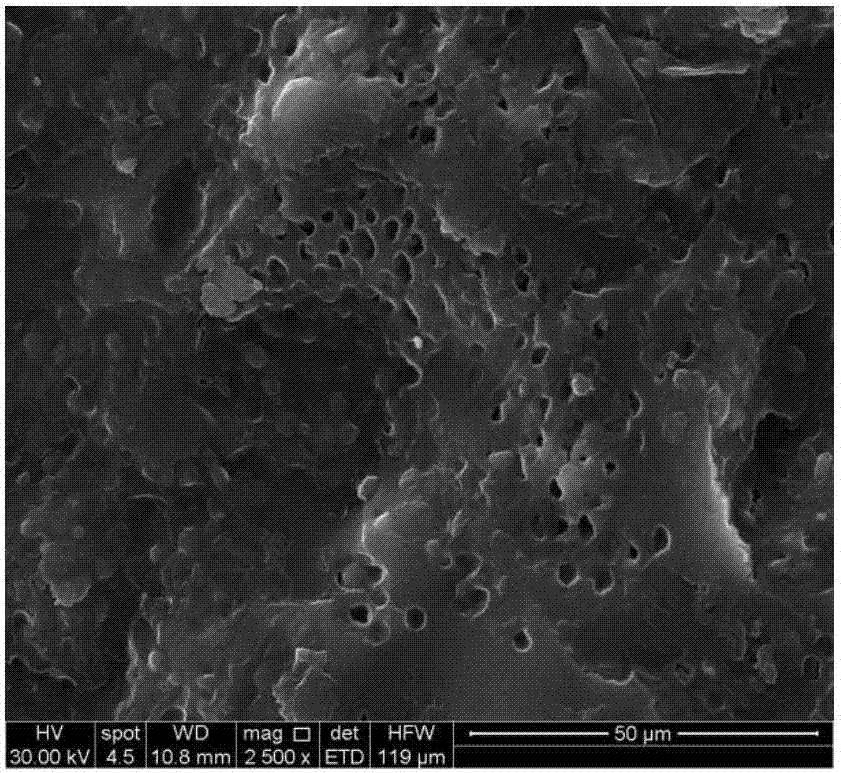

[0037] 3) Preparation of porous gel matrix: lower the temperature of the matrix A obtained above to 20°C, add microbial culture medium B, stir evenly at 20°C, and pour the mixed solution into a polytetrafluoroethylene plate by casting method , placed in a microwave oven for radiation to obtain a porous gel matrix C;

[0038] 4) The porous gel matrix C was placed in a blast drying oven at 45° C. f...

Embodiment 2

[0044] A preparation method of an adsorption material with shape memory function, comprising the steps of:

[0045] 1) Preparation of the shape memory functional composite material matrix: 20 parts of polyurethane elastomer, 20 parts of polyvinylpyrrolidone, and 20 parts of cellulose were dissolved in 1000 parts of deionized water according to the mass parts; at 20 ° C, the stirring speed was 40r / min, blending and stirring for 0.1 hour to obtain the shape memory functional composite material matrix A;

[0046] 2) Culture of microbial base: 10 parts of Bacillus and 10 parts of beef extract were mixed, and stirred evenly at 20°C to obtain microbial culture medium B;

[0047] 3) Preparation of porous gel matrix: raise the temperature of matrix A obtained above to 50°C, add microbial culture medium B, stir evenly at 50°C, pour the mixed solution into a polytetrafluoroethylene plate by casting method , irradiated with ultraviolet light to obtain a porous gel matrix C;

[0048] 4)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com