Plasticizer composition, resin composition, and preparing methods therefor

A resin composition, the technology of the composition, applied in the direction of coating, etc., can solve the problems of poor workability, high viscosity, low processability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

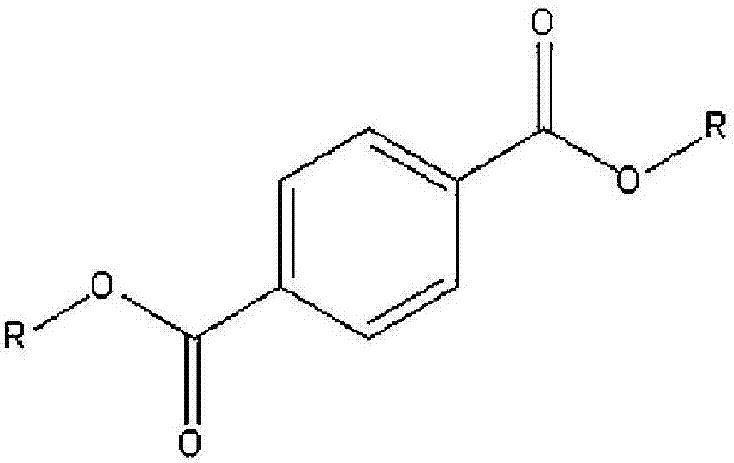

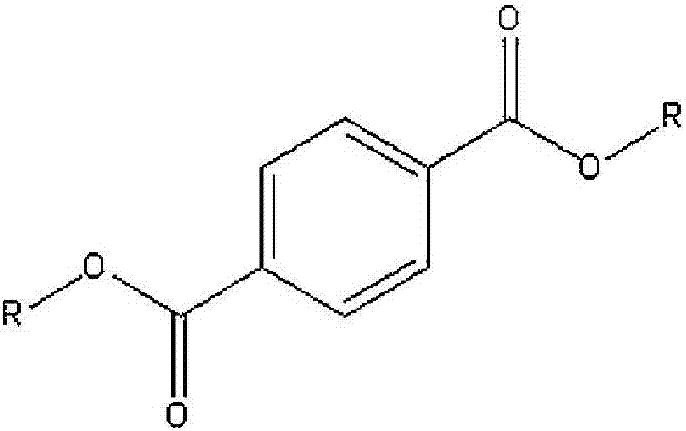

[0025] Preparation Example 1: Preparation of Diisononyl Terephthalate

[0026] 498.0 g of purified terephthalic acid (TPA), 1296 g of isononyl alcohol (INA) (TPA:INA molar ratio = 1.0:3.0) and 1.54 g (0.31 parts by weight relative to 100 parts by weight of TPA) of titanium-based The catalyst (tetraisopropyl titanate (TIPT)) was added to a 3L four-neck reactor equipped with a cooler, condenser, decanter, reflux pump, temperature controller, stirrer, etc., and the temperature of the reactor was Slowly increase to about 170°C. Produced water started to be generated at about 170°C, and the esterification reaction was carried out at a reaction temperature of about 220°C under atmospheric pressure for about 4.5 hours while continuously introducing nitrogen gas, and the reaction was terminated when the acid value reached 0.01.

[0027] After the reaction was completed, distillation extraction was performed under reduced pressure for 0.5 to 4 hours to remove unreacted raw materials. ...

preparation Embodiment 2

[0028] Preparation Example 2: Preparation of Diisobutyl Terephthalate

[0029] Use isobutanol instead of isononyl alcohol, react for 6 to 24 hours, use the same amount of methanesulfonic acid as the catalyst in Preparation Example 1, and carry out the same purification method as Preparation Example 1 to obtain p-benzene Diisobutyl dicarboxylate.

preparation Embodiment 3

[0030] Preparation Example 3: Preparation of Dibutyl Terephthalate

[0031] Dibutyl terephthalate was obtained in the same manner as in Preparation Example 2 except that butanol was used instead of isononanol.

[0032] Examples and Comparative Examples were prepared using the materials according to Preparation Examples 1 to 3 as follows.

[0033] [Table 1]

[0034] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com