Road marking paint and its production process

A coating and road technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, coatings, etc., can solve problems such as poor adhesion of fluorocarbon polymer coatings, and achieve enhanced paint film adhesion and excellent chemical stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

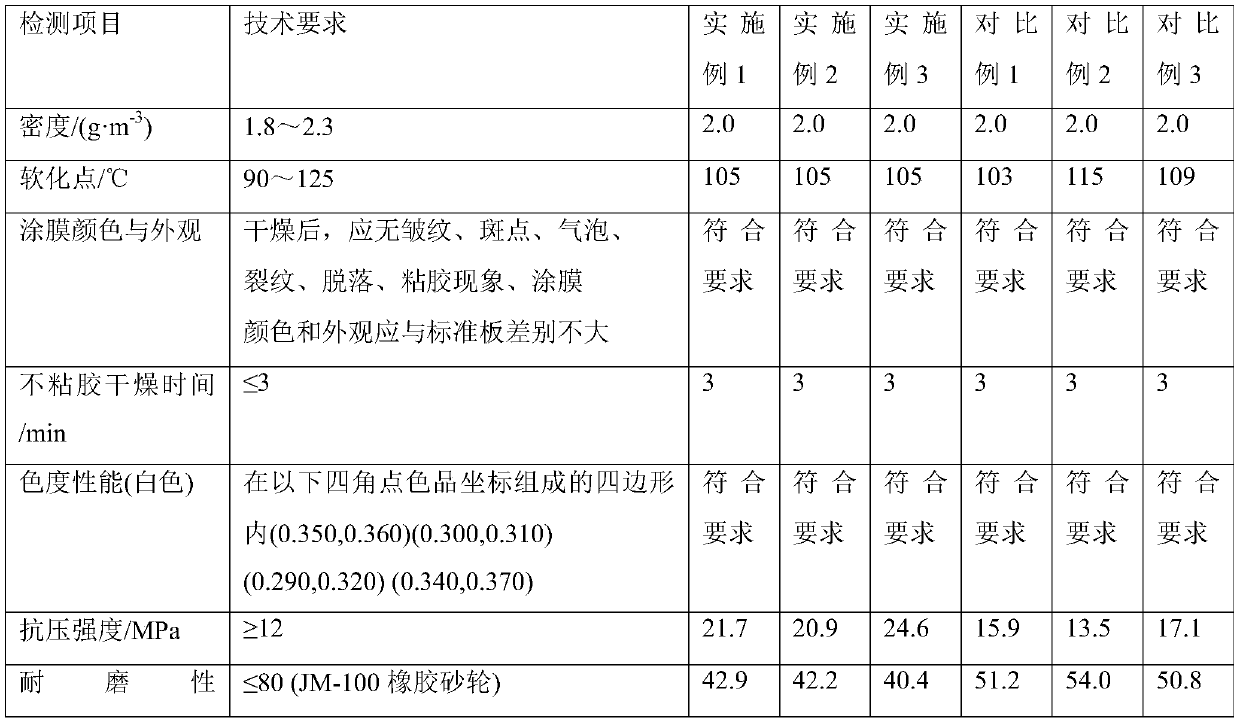

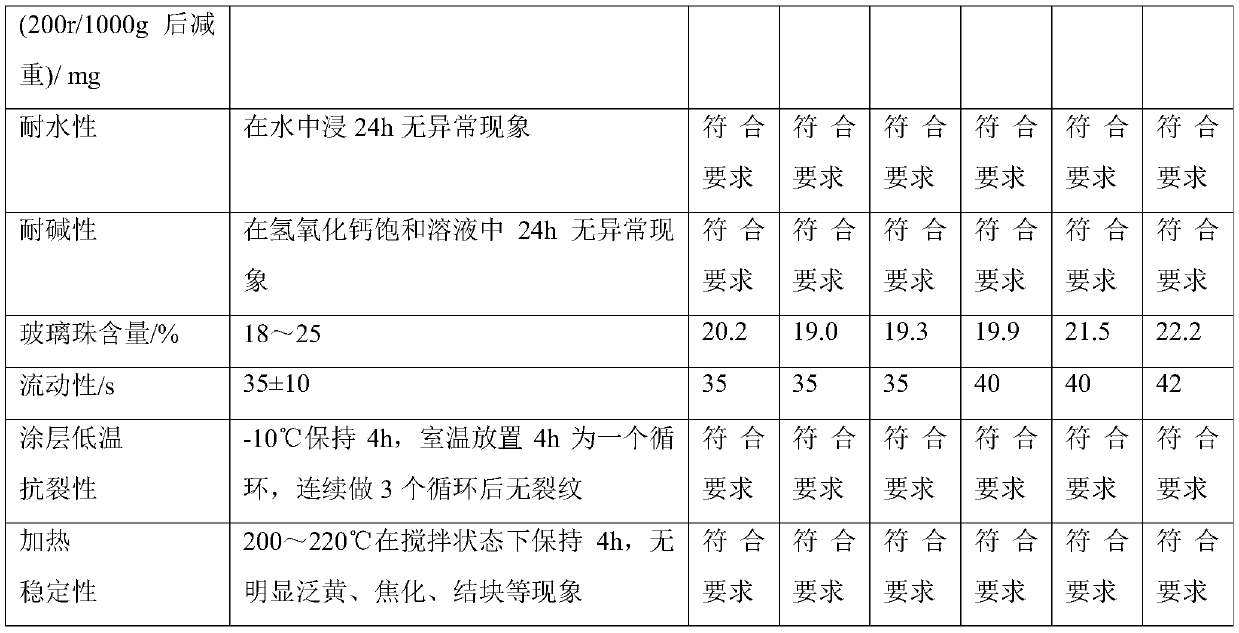

Examples

Embodiment 1

[0028] Preparation of fluorocarbon emulsion: Mix 10Kg tri-tert-butoxyvinylsilane, 6Kg vinylsulfonic acid, 10Kg 4-methyl-3-penten-2-one, 2Kg ammonium perfluorooctanoate with 18.4Kg deionized water, and Stir at high speed for pre-emulsification, pour the pre-emulsion into a high-pressure reactor, add 0.7Kg of ammonium persulfate and 0.7Kg of sodium bisulfite, vacuumize and fill with nitrogen, pour in 20Kg of tetrafluoroethylene gaseous monomer, at 65-80°C Under the temperature, the stirring reaction time is 60 ~ 150min, after the reaction is completed, it can be lowered to normal temperature.

[0029] The configuration of road marking paint: first mix 18Kg bentonite, 40Kg fluorocarbon emulsion with 0.1Kg polyacrylic acid, 0.1Kg dodecyl alcohol fat, 0.1Kg P-01 dispersant, 0.1Kg SP-01 defoamer and 0.1Kg polyacid After the bleeding bacteria are mixed evenly, add 2.3Kg rutile nano-silicon dioxide, 3.5Kg titanium dioxide, 10Kg energy-storage self-luminous material, 28Kg glass beads a...

Embodiment 2

[0031] Preparation of fluorocarbon emulsion: Mix 30Kg tri-tert-butoxyvinylsilane, 2Kg vinylsulfonic acid, 4Kg4-methyl-3-penten-2-one, 4KgOP-10 emulsifier with 12Kg deionized water, Stir at high speed for pre-emulsification, pour the pre-emulsion into a high-pressure reactor, add 1Kg of ammonium persulfate and 1Kg of sodium bisulfite, vacuumize and fill with nitrogen, and pour in 20Kg of tetrafluoroethylene gaseous monomer. Under the temperature, the stirring reaction time is 60-150 minutes, and it can be lowered to normal temperature after the reaction is completed.

[0032] The configuration of the road marking paint: first, 16Kg bentonite, 45Kg fluorocarbon emulsion, 0.14Kg polyacrylic acid, 0.14Kg dodecyl alcohol fat, 0.14Kg P-01 dispersant, 0.14Kg SP-01 defoamer and 0.14Kg more After the bleeding bacteria are mixed evenly, add 1.4Kg rutile nano-silicon dioxide, 4.3Kg titanium dioxide, 7Kg energy-storage self-luminous material,

[0033] 25Kg glass beads and 36Kg bentonite,...

Embodiment 3

[0035] Preparation of fluorocarbon emulsion: 20Kg tri-tert-butoxyvinylsilane, 4Kg vinylsulfonic acid, 14Kg4-methyl-3-penten-2-one, 3KgOP-10 emulsifier, 3Kg perfluorooctanoic acid ammonium and 19Kg deionized Mix with water, stir at high speed for pre-emulsification at room temperature, pour the pre-emulsion into a high-pressure reactor, add 0.5Kg ammonium persulfate and 0.5Kg sodium bisulfite, vacuumize and fill with nitrogen, and pour in 20Kg tetrafluoroethylene gaseous monomer, At a temperature of 65-80° C., the stirring reaction time is 60-150 minutes, and the temperature is lowered to normal temperature after the reaction is completed.

[0036] The configuration of the road marking paint: first, 17Kg bentonite, 50Kg fluorocarbon emulsion, 0.2Kg polyacrylic acid, 0.2Kg dodecyl alcohol fat, 0.2Kg P-01 dispersant, 0.2Kg SP-01 defoamer and 0.2Kg more After the bleeding bacteria are mixed evenly, add 1.8Kg rutile nano-silicon dioxide, 5Kg titanium dioxide, 4Kg energy-storage sel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com