Hollow polyester fiber with antibacterial and self-cleaning functions and preparation method thereof

A self-cleaning, hollow technology, applied in the manufacture of hollow filaments, cellulose/protein conjugated rayon, and conjugated synthetic polymer rayon, etc. Spinnability and other issues, to achieve significant antibacterial stability, good self-cleaning effect, and the effect of inhibiting production and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

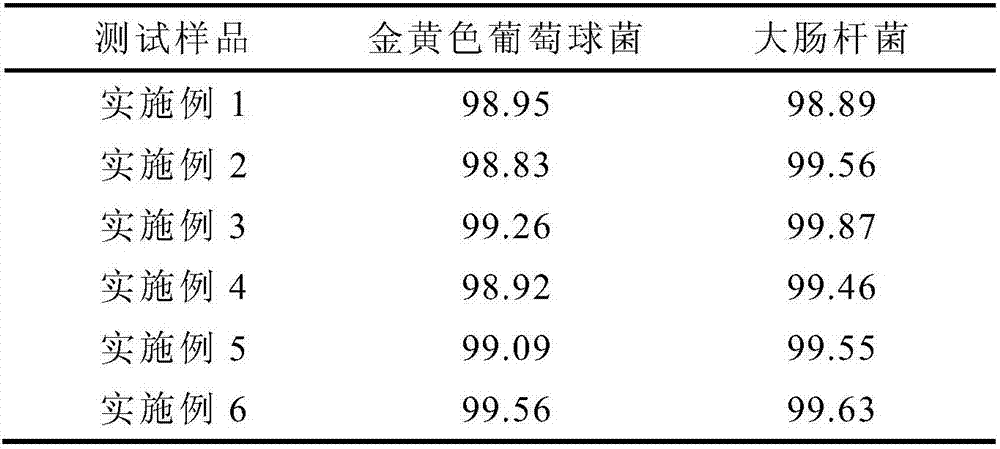

Examples

Embodiment 1

[0030] The preparation method of the polyester hollow fiber with antibacterial and self-cleaning functions comprises the following steps:

[0031] 1) Preparation of modified polyester composite material:

[0032] According to weight percentage, weigh the raw materials: unsaturated PET75%, unsaturated sulfadiazine silver salt 20%, azobisisobutyronitrile 5%; the raw materials are mixed evenly, and the processing temperature is 190 ℃ through the twin-screw extruder to be extruded successively. After extruding and granulating, the modified polyester composite material can be obtained;

[0033] 2) Preparation of hollow composite fibers:

[0034] By weight percentage, take 50% of modified polyester composite material and 50% of cellulose acetate butyrate, after mixing uniformly, a twin-screw extruder with a processing temperature of 190°C is extruded and granulated successively through a spinning temperature of 190°C. The hollow fiber spinning assembly at 200°C is melt blended and...

Embodiment 2

[0038] 1) Preparation of modified polyester composite material:

[0039] By weight percentage, weigh raw materials: unsaturated PBT 97.5%, N-(6-aminohexyl)-5-chloro-1-naphthalenesulfonamide hydrochloride 2.4%, azobisisoheptanonitrile 0.1%, and mix the raw materials Uniform, the modified polyester composite material can be obtained after the twin-screw extruder is extruded and pelletized at a processing temperature of 200°C;

[0040] 2) Preparation of hollow composite fibers:

[0041] By weight percentage, take 90% of modified polyester composite material and 10% of cellulose acetate butyrate, after mixing uniformly, the twin-screw extruder with the processing temperature of 200°C is extruded and granulated successively through the spinning temperature of 200°C. The hollow fiber spinning assembly at 220°C is melt blended and spun to obtain hollow composite fibers;

[0042] 3) Preparation of polyester hollow fibers with antibacterial and self-cleaning functions:

[0043] Imme...

Embodiment 3

[0045] 1) Preparation of modified polyester composite material:

[0046] According to the percentage by weight, raw materials were weighed: 95% unsaturated PTT, 2% unsaturated sodium sulfacetamide, 3% ammonium persulfate; the raw materials were mixed evenly, and the processing temperature was 210 ℃ through a twin-screw extruder successively through extrusion, manufacturing After pelleting, the modified polyester composite material is obtained;

[0047]2) Preparation of hollow composite fibers:

[0048] By weight percentage, get 60% of modified polyester composite material and 40% of cellulose acetate butyrate, after mixing uniformly, through the twin-screw extruder that processing temperature is 210 ℃ through extruding successively, after granulating, through spinning temperature is The hollow fiber spinning assembly at 230°C is melt blended and spun to obtain hollow composite fibers;

[0049] 3) Preparation of polyester hollow fibers with antibacterial and self-cleaning fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com