A method for manufacturing ultra-high-density ultra-high-strength plant fiberboard

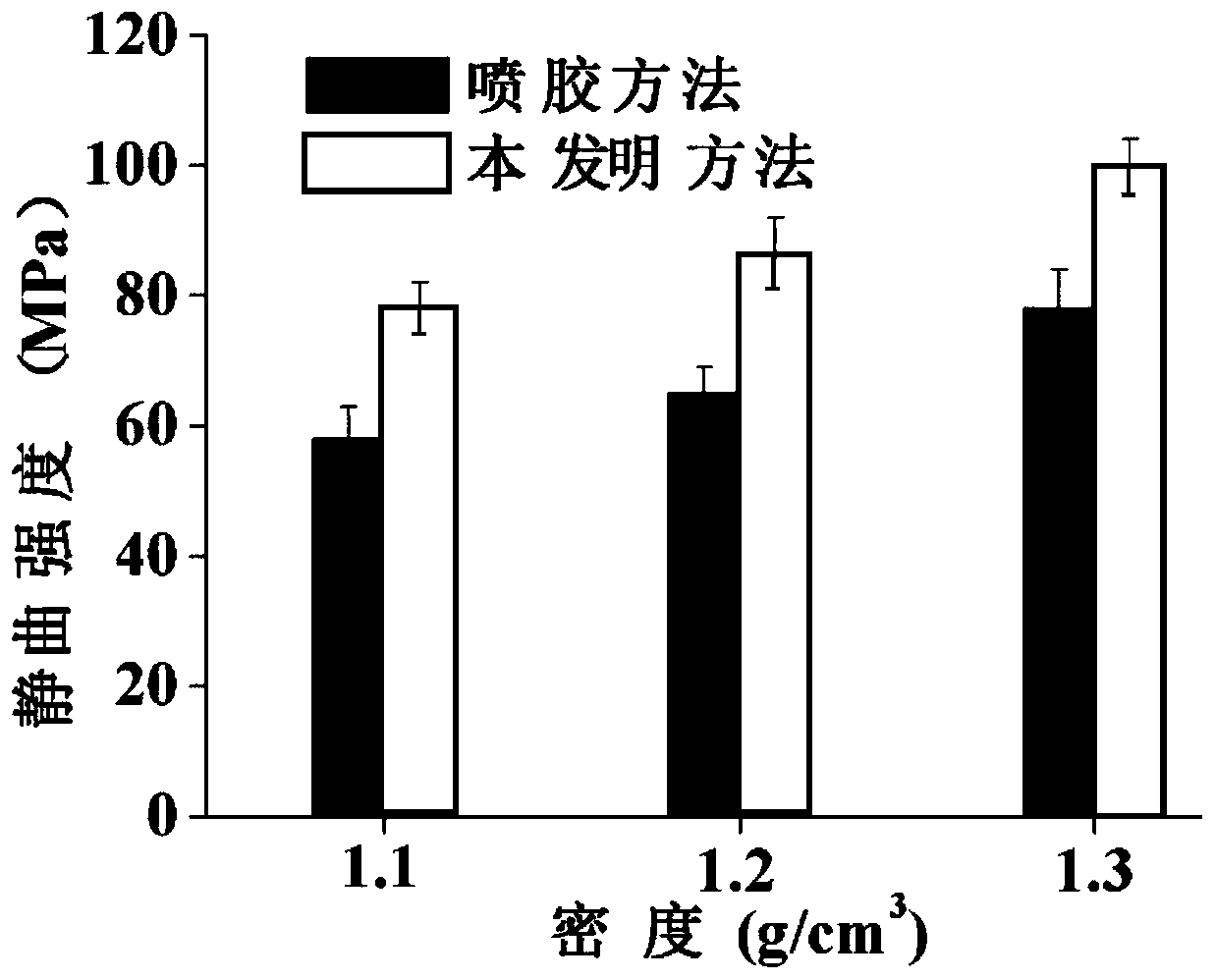

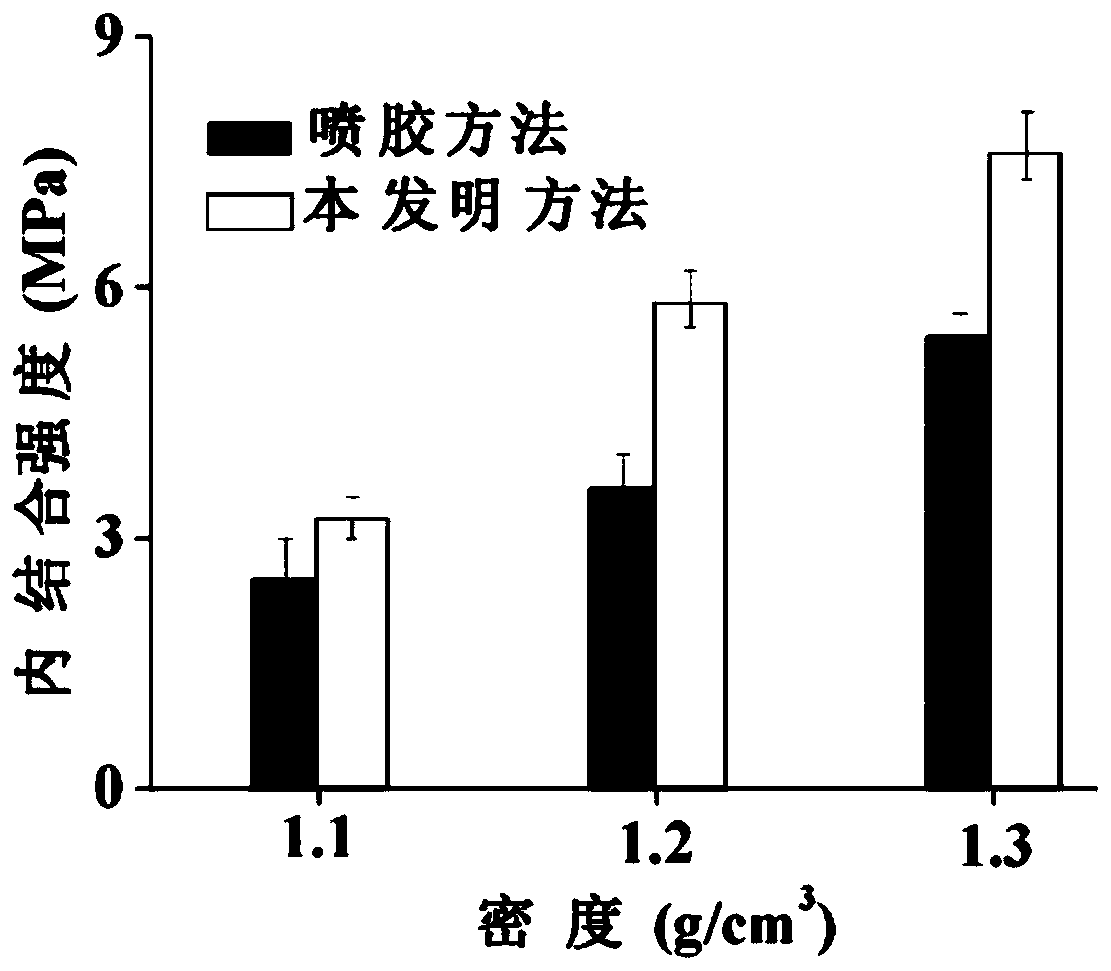

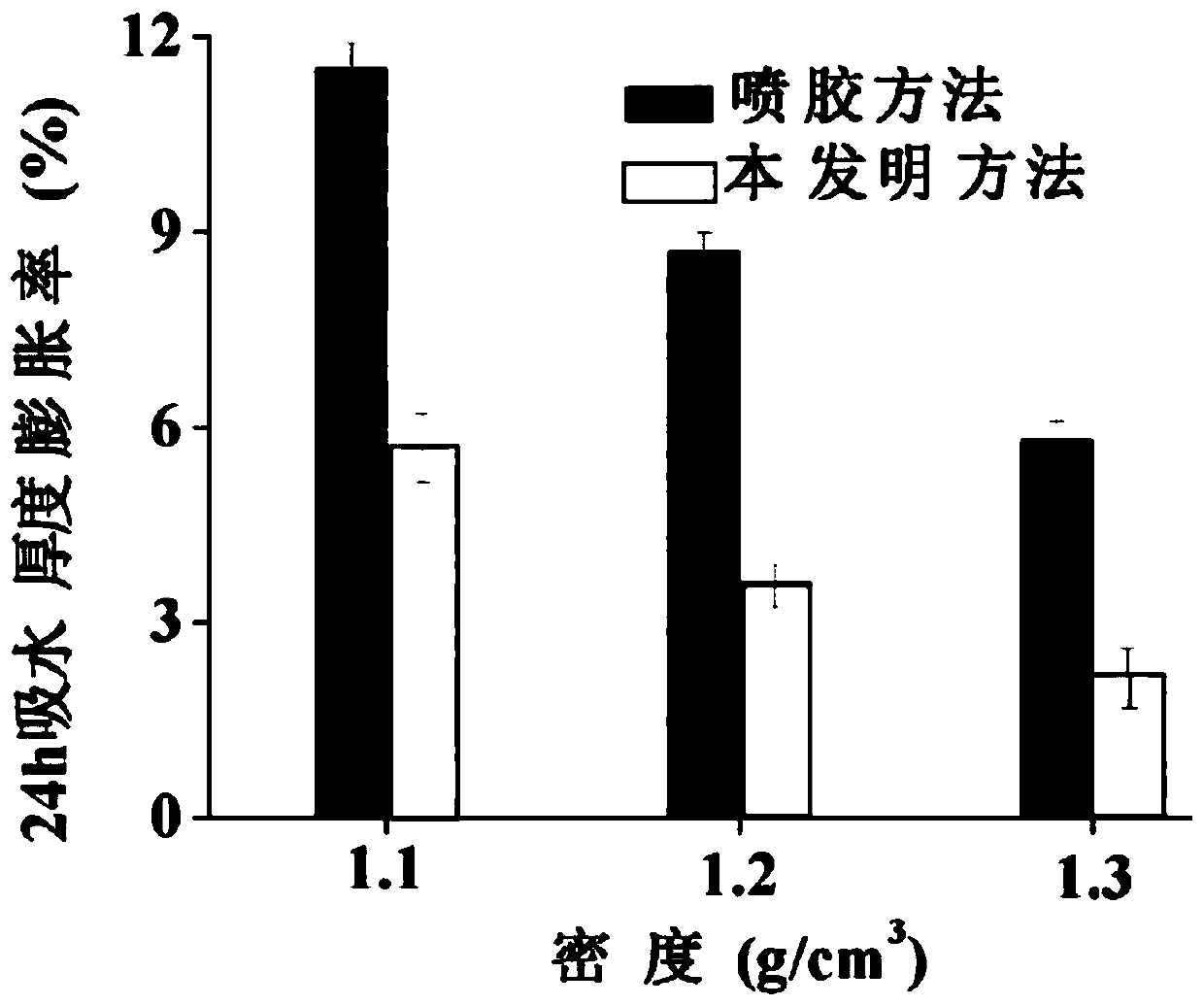

A plant fiber, ultra-high-strength technology, used in the manufacture of tools, flat products, pretreatment of molding materials, etc., can solve the problems of lack of large-diameter logs, low utilization rate of raw materials, low efficiency, etc., and achieve excellent mechanical properties. and water resistance, promoting production efficiency and transformation and upgrading, and improving the effect of physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Pave the wood fiber, and then use a cold press to pre-press it into a slab, and then add a low-concentration adhesive (20% aqueous solution of urea-formaldehyde resin, and add a phosphorus-based flame retardant whose mass is 20wt.% of the mass of urea-formaldehyde resin ) solution evenly (sprinkling amount is 3 times of the wood fiber mass) onto the wood fiber blank, and then the blank is sent to the cold press for 1 degumming in the way of "pressurization-pressure release". The liquid enters the surface and inside of the wood fiber, and the glue content of the degummed fiber accounts for 17wt.% of the fiber amount; then the degummed fiber is sent into the airflow drying chamber to dry the degummed fiber, and the moisture content of the dried fiber is 5wt.%. Send into paving machine again and it is paved into slab, now the gluing amount of wood fiber is 17%, and this slab is pressed into composite board with a flat plate hot press. The pressing temperature of the compos...

Embodiment 2

[0065] The wood fiber is paved, and then pre-pressed into a slab with a cold press, and then a low-concentration adhesive (a melamine resin aqueous solution with a concentration of 30%) is added, and a nitrogen-based flame retardant whose mass is 15wt.% of the melamine resin is added. ) evenly sprayed (sprinkling amount is 3 times the mass of wood fiber) onto the wood fiber blank, and then sent the blank into the cold press for degumming once by using the "pressure-relieving" method. During this process, the glue Enter the wood fiber surface and inside, the glue content of the fiber after degumming accounts for 25wt.% of the fiber amount; then send the degummed fiber into the airflow drying chamber to dry the fiber after degumming, the moisture content of the fiber after drying is 5wt.%, and then send Put it into a paving machine and pave it into a slab. At this time, the glue-dipping amount of the wood fiber is 25%, and the slab is pressed into a composite board with a flat-pl...

Embodiment 3

[0067]Pave the wood fiber, then pre-press it into a slab with a cold press, and then apply a low-concentration adhesive (an isocyanate organic solution with a concentration of 40%, and add a phosphorus-based flame retardant whose mass is 30wt.% of the isocyanate mass) Sprinkle evenly (the amount of spraying is 3 times the mass of wood fiber) on the wood fiber blank, and then send the blank into the cold press for degumming once by "pressurization-pressure release". During this process, the glue enters On the surface and inside of the wood fiber, the glue content of the fiber after degumming accounts for 35wt.% of the fiber amount; The paving machine paved it into a slab. At this time, the amount of glue dipping of the wood fiber was 35%, and the slab was pressed into a composite board with a flat-plate hot press. The pressing temperature of the composite plate is 120°C, the pressing pressure is 2MPa, the pressing time is 0.5min per mm of plate thickness, and the density of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com