Electrostatic spinning liquid for silicon dioxide fibers and method for preparing porous silica dioxide fibers by utilizing electrospinning method

A porous silica, electrospinning technology, applied in spinning solution preparation, fiber chemical characteristics, fiber processing and other directions, can solve the problem that the material flexibility is difficult to maintain, the fiber and its upper pore structure size is difficult to control, and the cumbersome experimental steps and other problems, to achieve the effect of good durability, good application prospects, and reduced control difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

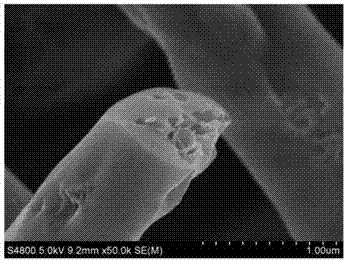

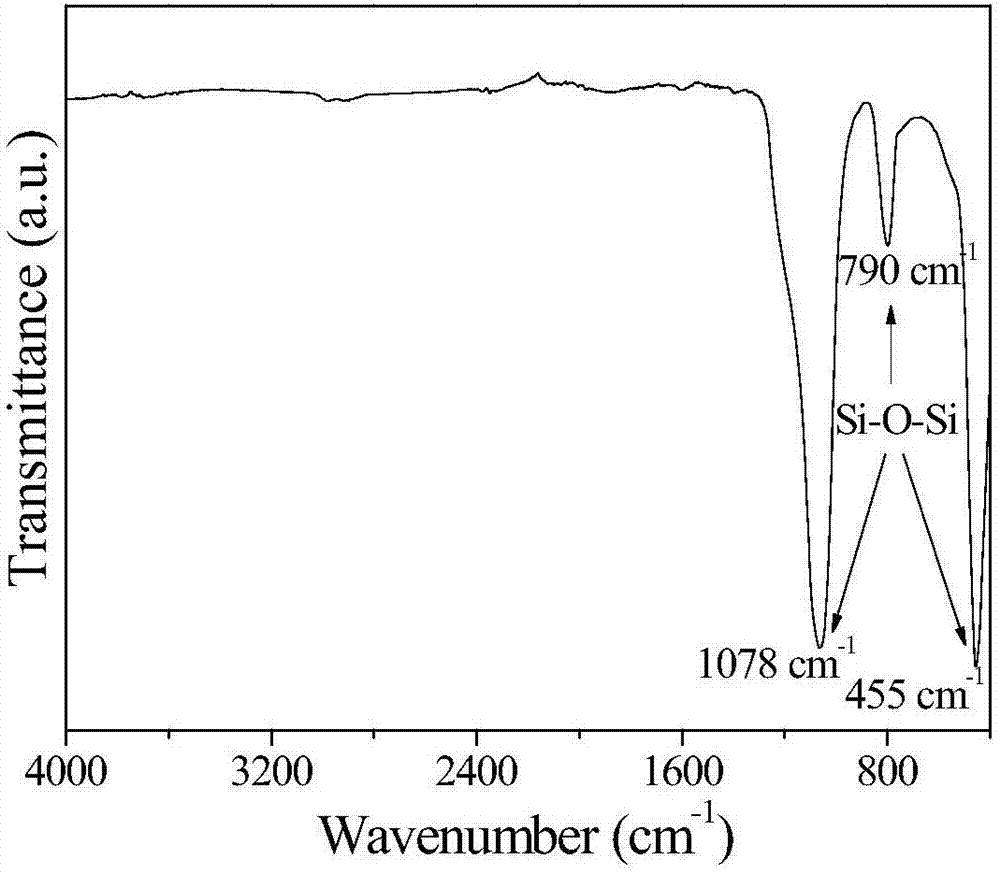

[0025] Step 1, take 1g of silica sol and add 50mg of carbon nanospheres with an average diameter of 110nm, ultrasonically disperse evenly (0.5h), then add 1g of PVA aqueous solution with a mass fraction of 11% therein, stir until uniform (4h), and obtain The homogeneous sol / pore forming agent / polyvinyl alcohol metastable system is the electrospinning solution;

[0026] Wherein, the preparation method of silica sol is: use orthoethyl silicate (TEOS) as silica sol precursor, use water as solvent, H 3 PO 4 (85%) As a catalyst, tetraethyl orthosilicate: water: H 3 PO 4 Be mixed in the ratio of 1:1:0.01 by mass ratio (wherein, H 3 PO 4 It needs to be added dropwise within 30-60 minutes), and then stirred at room temperature for 6 hours to fully hydrolyze and condense the inorganic precursor to form a silica sol;

[0027] Wherein, the preparation of the PVA aqueous solution: add PVA to water, heat to dissolve and stir evenly to obtain the PVA aqueous solution, which is set asid...

Embodiment 2

[0032] Step 1. Take 1 g of the silica sol prepared in Example 1 and add 75 mg of polymethyl methacrylate nanospheres with an average diameter of 300 nm. Ultrasonic dispersion is uniform (0.5 h), and then an aqueous PVA solution with a mass fraction of 11% is added thereto. 1g, stirred until uniform (4h), to obtain a homogeneous sol / pore forming agent / polyvinyl alcohol metastable system, which is the electrospinning solution.

[0033] Step 2. Inject the electrospinning solution into a 1mL syringe with a stainless steel needle, control the spinning speed to 250 μL / min, adjust the spinning voltage to 10kV, and adjust the nozzle (i.e., the stainless steel needle) to the receiving plate (covered with tinfoil) ) distance of 15cm, can be collected on the receiving plate to obtain silica / PMMA nanospheres / PVA composite fiber (fiber interweaving into film)

[0034] Step 3. Dry the obtained composite fiber (membrane) in an oven at 80°C for 2 to 4 hours, then place it in a muffle furnace,...

Embodiment 3

[0037]Step 1. Take 1g of silica sol and add 100mg of polystyrene nanospheres with an average diameter of 200nm, ultrasonically disperse evenly (0.5h), then add 1g of PVA aqueous solution with a mass fraction of 11%, and stir until uniform (4h) , to obtain a homogeneous sol / pore forming agent / polyvinyl alcohol metastable system, which is the electrospinning solution.

[0038] Step 2. Inject the electrospinning solution into a 1mL syringe with a stainless steel needle, control the spinning speed to 250 μL / min, adjust the spinning voltage to 10kV, and adjust the nozzle (i.e., the stainless steel needle) to the receiving plate (covered with tinfoil) ) at a distance of 15 cm, the silica / PS nanosphere / PVA composite fiber (fiber interwoven into a film) can be collected on the receiving plate.

[0039] Step 3. Dry the obtained composite fiber (membrane) in an oven at 80°C for 2 to 4 hours, then place it in a muffle furnace, heat it to 750°C in air at a heating rate of 10°C / min, and ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com