Preparation method of Pd/Ag nano-alloy catalyst for direct ethanol fuel cell

A nano-alloy and fuel cell technology, applied in the direction of fuel cells, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of high cost, physical injury of operators, etc., and achieve low equipment requirements and short production cycle Short and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Preparation method

[0042] A Pd / Ag nano-alloy catalyst for direct ethanol fuel cells, prepared by the following method:

[0043] (1) Add 4 mL of water and 20 mL of ethanol in turn to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0044] (2) Add 0.007 g of Pd(NO 3 ) 2 Powder, 0.012 g AgNO 3 , 0.004 g of sodium citrate and 0.0982 g of PVP were added to the water-ethanol mixed solution system, and the prepared solution was placed on a constant temperature magnetic stirrer at 20 ° C for 2 h;

[0045] (3) Put the evenly stirred reaction solution in a self-designed light reaction box, and place it under a 200 W ordinary commercially available incandescent light for 2 hours in parallel to irradiate;

[0046] (4) The obtained black precipitate was separated by centrifugation, washed twice with absolute ethanol and deionized water, and dried in a vacuum oven at 35 °C for 48 h, which was the Pd / Ag nano-alloy catalyst material.

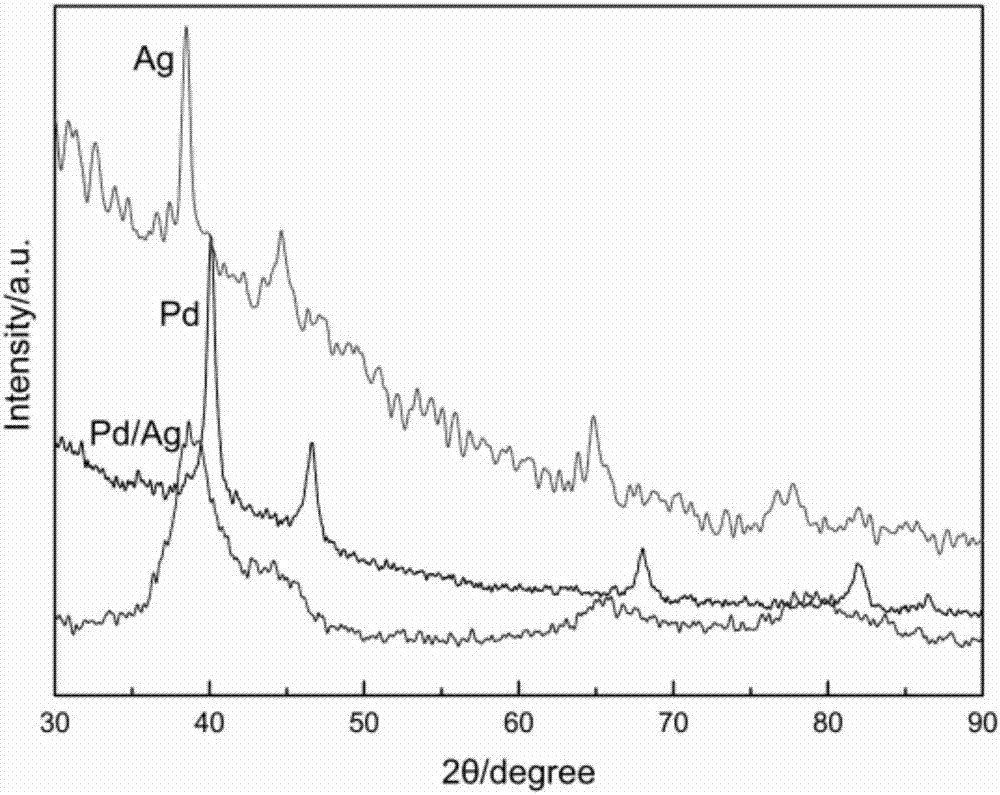

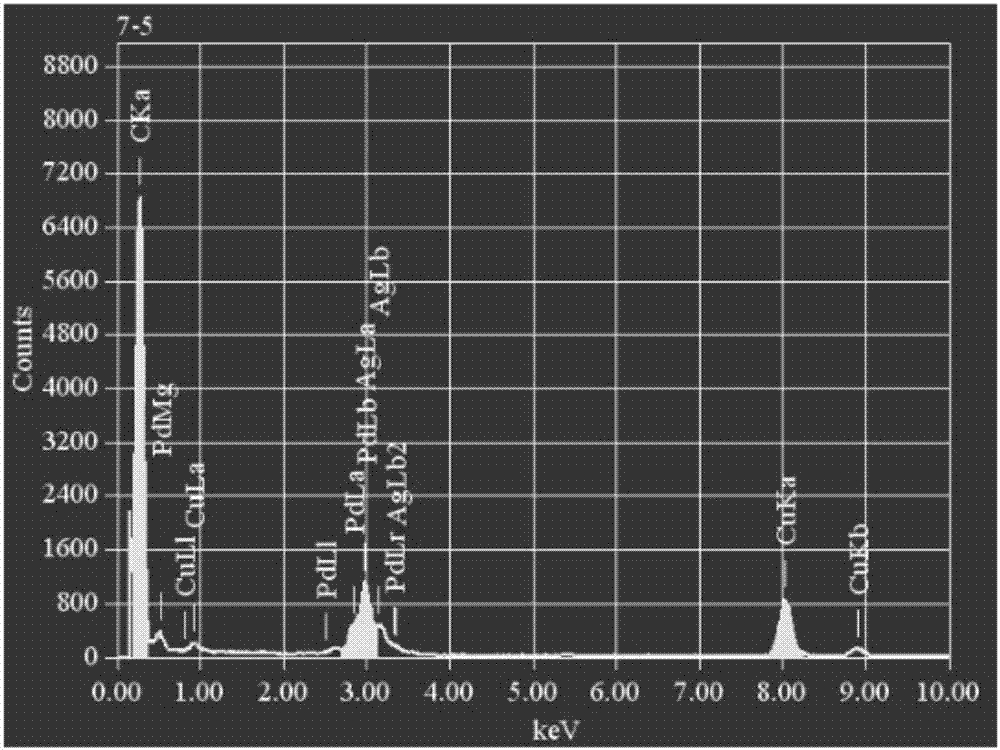

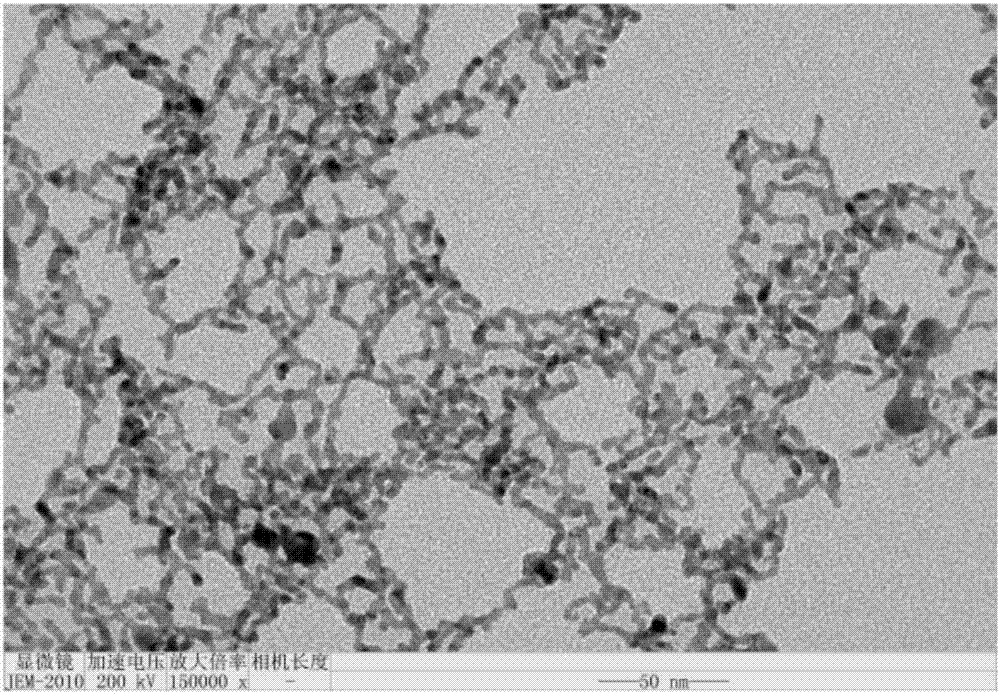

[0047] T...

Embodiment 2

[0055] 1. Preparation method

[0056] A Pd / Ag nano-alloy catalyst for direct ethanol fuel cells, prepared by the following method:

[0057] (1) Add 4 mL of water and 20 mL of ethanol in turn to the reaction vessel, and stir to obtain a water-ethanol mixed solution system;

[0058] (2) Add 0.007 g of Pd(NO 3 ) 2 Powder, 0.005 g AgNO 3 , 0.001 g of sodium citrate and 0.098 g of PVP were added to the water-ethanol mixed solution system, and the prepared solution was placed on a constant temperature magnetic stirrer at 23 ° C for 2 h;

[0059] (3) Put the evenly stirred reaction solution in a self-designed light reaction box, and place it under a 200 W ordinary commercially available incandescent light for 2 hours in parallel to irradiate;

[0060] (4) The obtained black precipitate was separated by centrifugation, washed twice with absolute ethanol and deionized water, and dried in a vacuum oven at 45 °C for 12 h, which was the Pd / Ag nano-alloy catalyst material.

[0061] Th...

Embodiment 3

[0067] 1. Preparation method

[0068] A Pd / Ag nano-alloy catalyst for direct ethanol fuel cells, prepared by the following method:

[0069] (1) Add 6 mL of water and 12 mL of ethylene glycol in sequence to the reaction vessel, and stir to obtain a water-alcohol mixed solution system;

[0070] (2) Add 0.007 g of Pd(NO 3 ) 2 , 0.002 g AgNO 3 , 0.004 g of sodium citrate and 0.098 g of PVP were added to the water-ethanol mixed solution system, and the prepared solution was placed on a constant temperature magnetic stirrer at 25 ° C for 2 h;

[0071] (3) Put the evenly stirred reaction solution in a self-designed light reaction box, and place it under a 15 W ordinary commercially available energy-saving light for 12 h in parallel irradiation;

[0072] (4) The obtained black precipitate was separated by centrifugation, washed twice with absolute ethanol and deionized water, and dried in a vacuum oven at 40 °C for 24 h, which was the Pd / Ag nano-alloy catalyst material.

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com