Titanium-copper dissimilar metal joint welding method

A technology of heterogeneous metals and welding methods, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of insufficient contact interface temperature, and achieve the effect of high weld interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

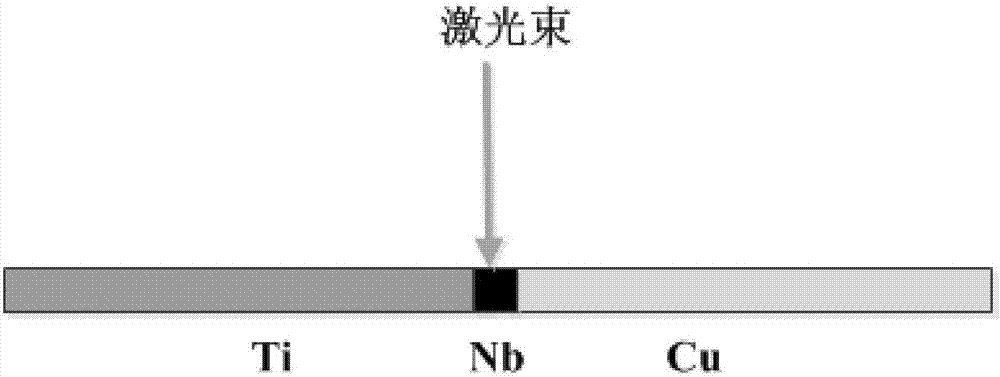

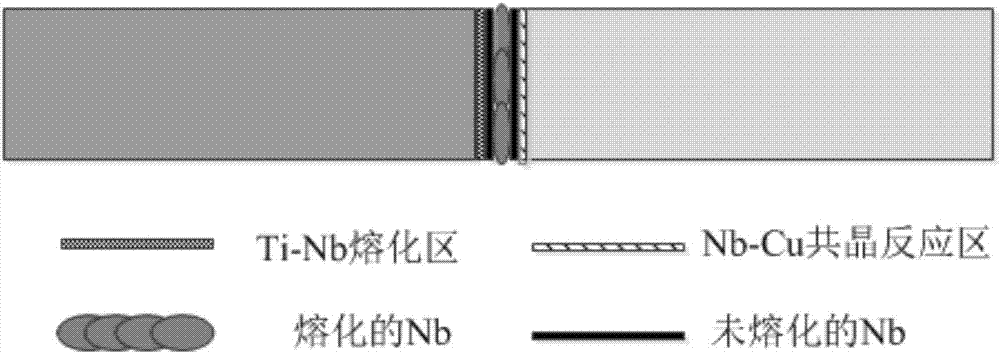

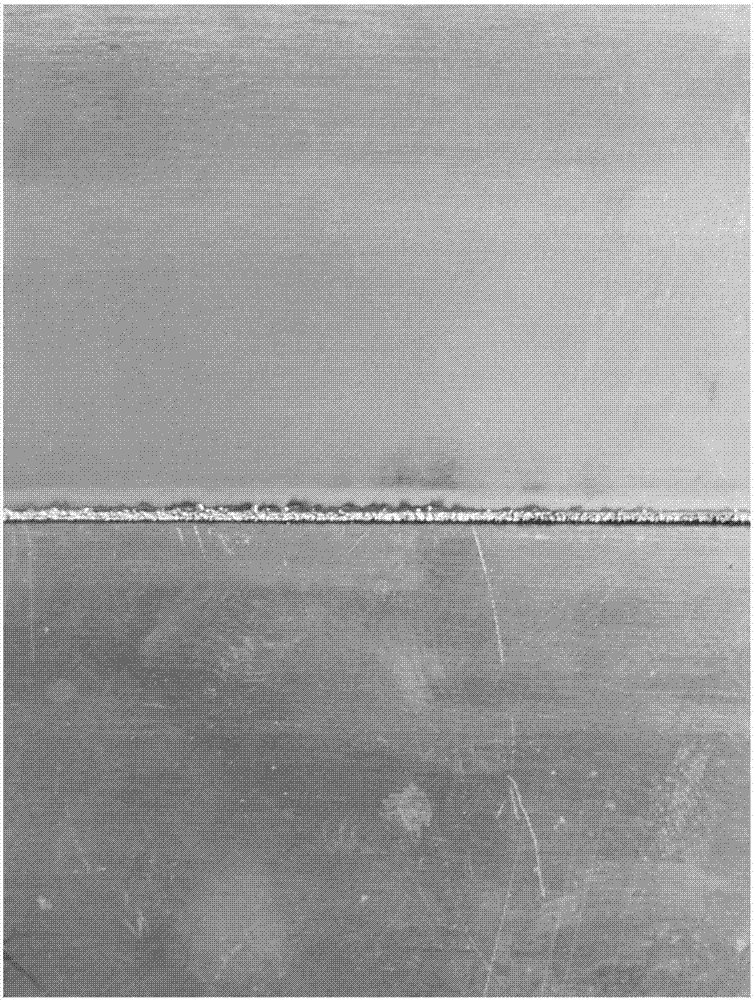

[0037] Pulse laser welding is performed on TC4 titanium alloy and pure Cu. The CT4 titanium alloy plate is the same size as the pure copper plate, which is 100mm (length) × 50mm (width) × 1.2mm (thickness). The 1mm thick niobium interlayer solder Placed between the TC4 titanium alloy plate and the pure copper plate interface, there is no gap between the niobium intermediate layer and the titanium alloy and pure copper interface respectively, and the thickness of the niobium intermediate layer solder is 0.8mm (that is, the distance between the Ti / Nb interface and the Nb / Cu interface) , place the pulsed laser spot at a distance of 0.4 mm from the Ti / Nb interface, and perform pulsed laser welding under a double-sided argon protective atmosphere, such as figure 1 with figure 2As shown, through the control of pulsed laser parameters, the melting is controlled in the area near the Ti / Nb interface. There is an unmelted Nb layer between the Ti / Nb interface and the Nb / Cu interface, an...

Embodiment 2

[0043] Pulse laser welding is performed on TC4 titanium alloy and pure Cu. The CT4 titanium alloy plate is the same size as the pure copper plate, which is 100mm (length) × 50mm (width) × 1.0mm (thickness). The 0.8mm thick niobium interlayer The solder is placed between the interface between the TC4 titanium alloy plate and the pure copper plate. There is no gap between the niobium interlayer and the titanium alloy and pure copper interface respectively. The width of the niobium interlayer solder is 1.0mm (that is, the distance between the Ti / Nb interface and the Nb / Cu interface ), the pulsed laser spot was placed at a distance of 0.6 mm from the Ti / Nb interface, and the pulsed laser welding was performed under a double-sided argon protective atmosphere. The pulsed laser welding process parameters were: laser peak power 1.5kW, pulse width 12ms, pulse frequency 40Hz, The welding speed is 400mm / min, the defocusing amount is 0mm, and in the double-sided protective atmosphere, the ...

Embodiment 3

[0047] Pulse laser welding is performed on TC4 titanium alloy and pure Cu. The CT4 titanium alloy plate is the same size as the pure copper plate, which is 100mm (length) × 50mm (width) × 1.0mm (thickness). The 1.2mm thick niobium interlayer The solder is placed between the interface between the TC4 titanium alloy plate and the pure copper plate. There is no gap between the niobium interlayer and the titanium alloy and pure copper interface respectively. The width of the niobium interlayer solder is 0.8mm (that is, the distance between the Ti / Nb interface and the Nb / Cu interface ), the pulsed laser spot was placed at a distance of 0.5 mm from the Ti / Nb interface, and pulsed laser welding was performed under an argon protective atmosphere on both sides to obtain a titanium-copper heterogeneous metal joint.

[0048] The pulse laser welding process parameters are: laser peak power 1.5kW, pulse width 18ms, pulse frequency 50Hz, welding speed 300mm / min, defocus amount 0.3mm, double-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com