Novel oxidizing-resistant nanometer copper soldering paste and preparation method and application thereof

An anti-oxidation and nano-copper technology, applied in transportation and packaging, metal processing equipment, ion implantation plating, etc., can solve problems such as reducing joint strength and interface strength, accelerating copper oxidation, and affecting sintering quality, so as to improve sintering quality , the effect of improving the strength of the joint and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

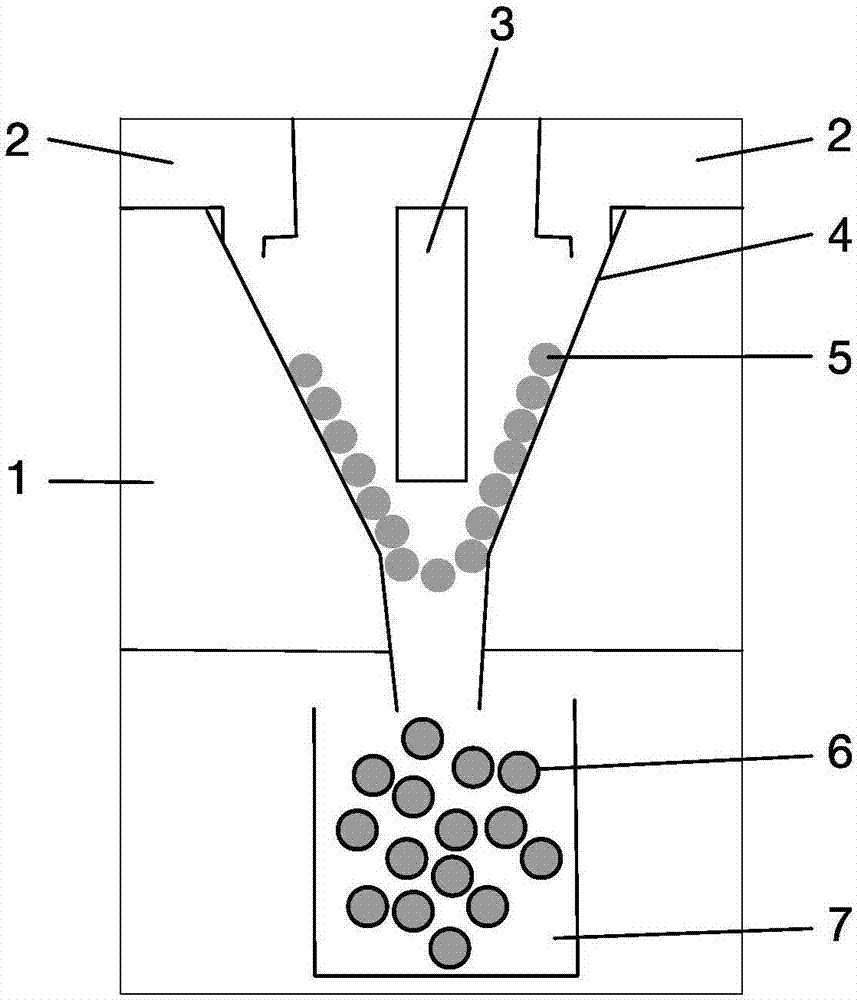

[0041] Step 1, such as figure 1 The magnetron sputtering method is used to prepare the coated nano-copper powder particles. Take the spherical nano-copper powder with a particle diameter of 20-80nm and pour it into the inverted cone-shaped rotatable lower hopper 4 through the feeding chamber 2. The nano-copper powder 5 moves in a spiral in the rotatable lower hopper 4 and falls into the magnetron sputtering. The process vacuum generation chamber 1 bombards the columnar silver or gold columnar target 3 with gas ions, knocks out its atoms and deposits them on the surface of the nano-copper powder 5 to form a silver or gold metal coating 6 . Among them, the rotation rate of the rotatable lower hopper 4 is controlled by the motor, and then the rotation rate of the nano-copper powder is controlled; the coating thickness is controlled by controlling the magnetron sputtering process parameters, including the sputtering angle and incident energy; thus, uniform A consistent metal coat...

Embodiment 2

[0046] like image 3 and Figure 4 As shown, the new anti-oxidation nano-copper solder paste 9 prepared in Example 1 is coated on the substrate 10 by a screen printing process with a scraper 8 , and the chip or device 11 is surface mounted. Place the mounted sample on the heating plate 13, fill the sintering furnace cavity 19 with argon through the air inlet 15, set the temperature of the heating plate 13 to 150°C, and preheat for 2 minutes. Then, the gas inside the sintering furnace cavity 19 is discharged from the gas outlet 16 through the vacuum pump 17, and the pressure in the sintering furnace cavity 19 is adjusted through the vacuum gauge 18 to form a negative pressure; at this time, the temperature of the heating plate 13 is quickly raised to 310° C. Hold for 15 minutes to complete the sintering process and form a strong interconnection joint.

Embodiment 3

[0048] like image 3 and Figure 4 As shown, a new anti-oxidation nano-copper solder paste 9 is coated on a substrate 10 by a screen printing process with a scraper 8 , and a chip or device 11 is surface mounted. Place the mounted sample on the heating plate 13, fill the sintering furnace cavity 19 with argon gas through the air inlet 15, set the temperature of the heating plate to 150°C, and move the movable support 12 upward until the sample touches the fixed Push the pillar 14 and apply a pressure of 5 MPa, rapidly raise the temperature to 220° C. and keep it for 10 minutes to complete the sintering process and form a firm interconnection joint.

[0049] The chip was mounted on the substrate using traditional nano-copper solder paste, and it was raised from room temperature to 200 °C under nitrogen atmosphere and kept for 10 minutes. The joint shear strength obtained under different heating rates was as follows: Figure 5 As shown, the highest is 5MPa; or directly sintere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com