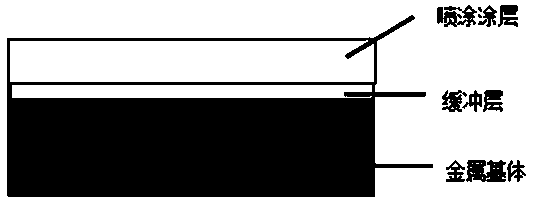

An internally heated integrated evaporation basket with a buffer layer of alumina porous structure

A porous structure and buffer layer technology, which is applied in vacuum evaporation plating, coating, metal material coating process, etc., can solve the problems of low thermal efficiency, high energy consumption of equipment, easy to break, etc., and achieve low porosity and increased strain Tolerance, the effect of reducing manufacturing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Mix 50g of alumina submicron powder, 15ml of ethanol and 10ml of acetone, add 1g of triethanolamine as a dispersant, 0.15g of carboxymethyl cellulose as a rheological agent and pore-forming agent, and 1g of PVB as a binder, and put them in a planetary ball mill Ball mill for 2 hours and mix evenly to form a ceramic slurry with a pH value of 10. The tungsten basket soaked in 15wt% sodium hydroxide solution ( figure 2 ) into the slurry, spin-coated and dipped until the coating thickness is 350 μm and evenly covered. After natural drying, it is sintered in an aerobic atmosphere in a high-temperature box furnace. The sintering temperature is 25-500 ° C, and the heating rate is 2 ° C / min , and kept at 500°C for 2 hours; then the green body was sintered in a vacuum tube furnace, the temperature was 25°C~1650°C and the temperature was raised slowly, the heating rate was 2°C / min below 1400°C, and the heating rate was 0.8 at the stage of 1400~1650°C ℃ / min, 1650 ℃ for 30 minu...

Embodiment 2

[0038] Mix 50g of alumina powder with a particle size of 35~45μm, 15ml of ethanol and 15ml of acetone, add 0.5g of triethanolamine as a dispersant, 0.15g of carboxymethyl cellulose as a rheological agent and pore-forming agent, and 1g of nitrocellulose as a binder , and evenly mixed in a planetary ball mill for 2 hours to form a ceramic slurry with a pH value of 11. The tungsten basket ( figure 2 ) into the slurry, spin-coated and dipped until the coating thickness is 150 μm and covered evenly. After natural drying, it is sintered in an aerobic atmosphere in a high-temperature box furnace. The sintering temperature is 25-500 ° C, and the heating rate is 2 ° C / min , and kept at 500°C for 2 hours; then the green body was sintered in a tube furnace in vacuum, the temperature was slowly raised from 25°C to 1650°C, the heating rate was 1°C / min below 1400°C, and the heating rate was 0.9 at the stage of 1400°C to 1650°C ℃ / min, 1650 ℃ for 60 minutes, and the cooling process is con...

Embodiment 3

[0041] Add 110g of alumina powder with a particle size of 1.5~5μm, 60ml of ethanol and 40ml of acetone mixed solvent, add 1.5g of triethanolamine as a dispersant, 1g of carboxymethyl cellulose as a rheological agent and pore-forming agent, and 3g of nitrocellulose as a binder, Mix evenly in a planetary ball mill for 2 hours to form a ceramic slurry with a pH value of 10. The tungsten basket soaked in the high-concentration silica sol solution ( figure 2 ) into the slurry, spin-coated and dipped until the coating thickness is 500 μm and covered evenly. After natural drying, it is sintered in an aerobic atmosphere in a high-temperature box furnace. The sintering temperature is 25-500 ° C, and the heating rate is 2 ° C / min , and kept at 500°C for 2 hours; then put the green body in a vacuum tube furnace for sintering, the temperature is 25°C~1650°C and the temperature is raised slowly, the heating rate is 2°C / min below 1400°C, and the heating rate is 1 at the stage of 1400~165...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com