Diamond grinding wheel and preparation method thereof

A diamond grinding wheel and diamond technology, used in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of poor grinding wheel grinding effect, diamond abrasive falling off, poor impact resistance, etc., and achieve good grinding ability. , The effect of increased bonding force and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

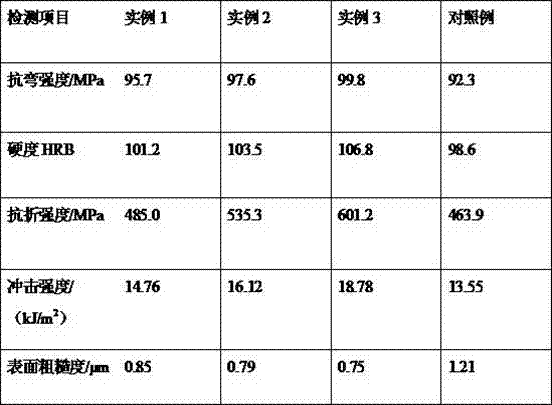

Examples

example 1

[0027] In parts by weight, choose 80 parts of diamond micropowder, 5 parts of sodium citrate, 1 part of ferropyroxene, 1 part of aluminum powder, 2 parts of albite, 0.3 part of copper powder, and 0.1 part of zinc powder; Sodium citrate was added to 10 times the mass of water to obtain a sodium citrate solution, and then added ferropyroxene, aluminum powder, albite, copper powder and zinc powder to the sodium citrate solution in sequence, and added to a ball mill jar for grinding for 3 hours to obtain Abrasives: put the abrasives into the reaction kettle, add diamond powder, heat to 200°C, stir for 10 minutes, then discharge, put the mixture in an oven, dry at 100°C for 8 hours, and add a vacuum after the dry product is obtained In the furnace, heat to 1100 ° C, keep warm for 10 minutes, cool to room temperature, and take out the furnace to obtain the diamond base material; in terms of parts by weight, 15 parts by mass fraction of 20% nano-silica sol, 10 parts of nano-titanium d...

example 2

[0029]In parts by weight, choose 90 parts of diamond micropowder, 8 parts of sodium citrate, 2 parts of ferropyroxene, 2 parts of aluminum powder, 3 parts of albite, 0.4 part of copper powder, and 0.2 part of zinc powder; Sodium citrate was added to water with 10 times the mass to obtain a sodium citrate solution, and to the sodium citrate solution was sequentially added ferropyroxene, aluminum powder, albite, copper powder and zinc powder, and added to a ball mill jar for grinding for 4 hours to obtain Abrasives: put the abrasives into the reaction kettle, add diamond powder, heat to 210°C, stir for 13 minutes, then discharge, put the mixture in an oven, dry at 110°C for 9 hours, and add the dried product to vacuum In the furnace, heat to 1150 ° C, keep it warm for 13 minutes, cool to room temperature, and take it out of the furnace to obtain the diamond base material; in terms of parts by weight, 18 parts by mass fraction of 20% nano-silica sol, 15 parts of nano-titanium diox...

example 3

[0031] In parts by weight, choose 100 parts of diamond micropowder, 10 parts of sodium citrate, 3 parts of ferropyroxene, 3 parts of aluminum powder, 4 parts of albite, 0.5 part of copper powder, and 0.3 part of zinc powder; Sodium citrate was added to 10 times the mass of water to obtain a sodium citrate solution. To the sodium citrate solution was added successively ferropyroxene, aluminum powder, albite, copper powder and zinc powder, added to a ball mill and ground for 5 hours to obtain Abrasives: put the abrasives into the reaction kettle, add diamond powder, heat to 220°C, stir for 15 minutes and discharge, put the mixture in the oven, dry at 120°C for 10 hours, and add the dry product to vacuum In the furnace, heat to 1200 ° C, keep warm for 15 minutes, cool to room temperature, and take out the furnace to obtain the diamond base material; in parts by weight, 20 parts by mass fraction of 20% nano-silica sol, 20 parts of nano-titanium dioxide, 3 parts of starch, 10 parts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com