A kind of graphene-sheet conductive mica oil tank electrostatic conductive anti-corrosion coating and preparation method thereof

A technology of anti-corrosion coatings and conductive mica, applied in the direction of conductive coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of low transparency or fullness of the coating, poor adhesion, difficult dispersion, etc., to achieve the reaction process Ease of control, easy formation of conductive pathways, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] Preparation of carboxyl-modified graphene

[0036] Put 2.0g of graphene in a 150ml single-necked flask, then pour 50ml of concentrated sulfuric acid, magnetically stir for 5h, ultrasonically oscillate for 4h-5h, then add concentrated nitric acid into the flask (the volume ratio of concentrated sulfuric acid to concentrated nitric acid is 4:1) , Stir magnetically for 30 minutes, transfer to a constant temperature of about 150°C to condense and reflux for 2 hours, take out the mixture, dilute it with ice water, and then filter it repeatedly with a filter membrane with a smaller pore size until the pH is close to 7, and place the filtered product in Dry in a constant temperature drying oven at 50° C. for 8 hours to obtain carboxyl-modified graphene powder, also known as modified graphene (acidification).

[0037] Preparation of graphene grafted with silane coupling agent

[0038] Add 10-20 drops of hydrochloric acid to 50ml of absolute ethanol solution, adjust the pH valu...

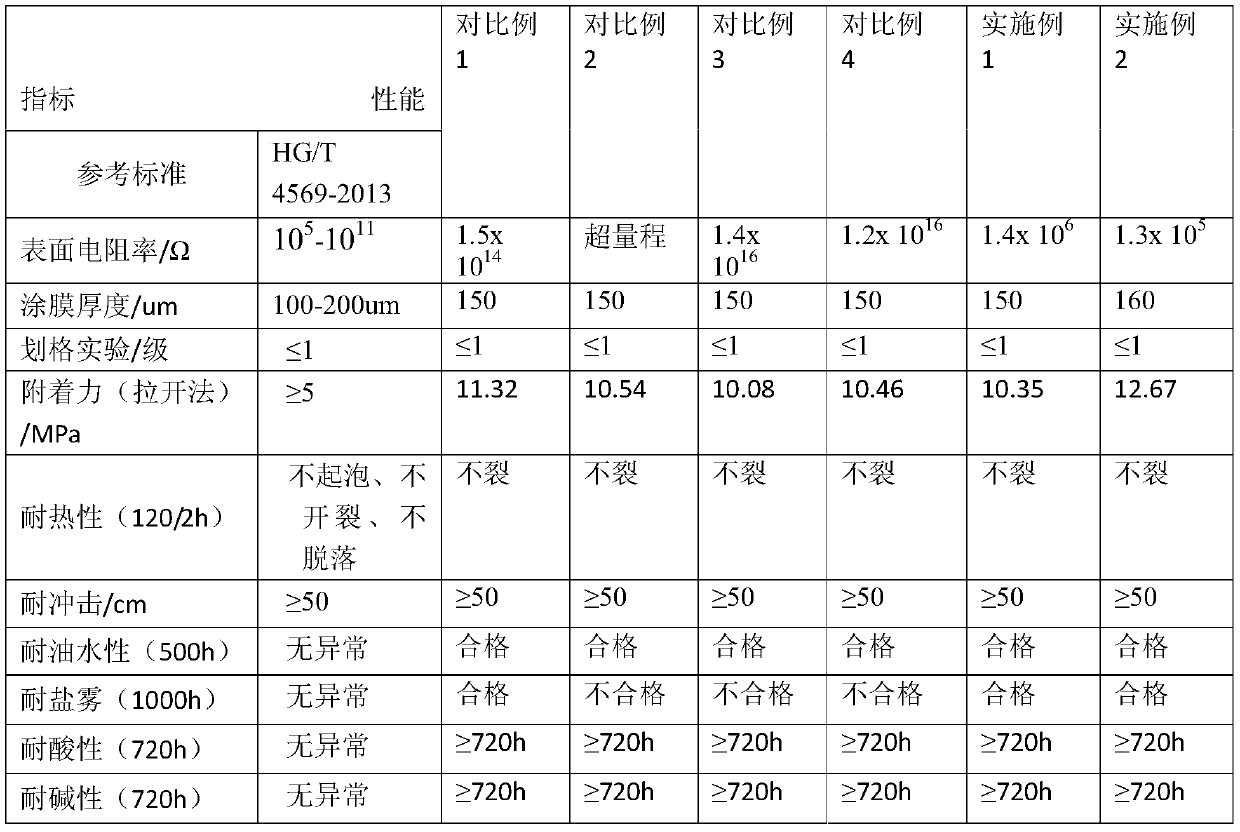

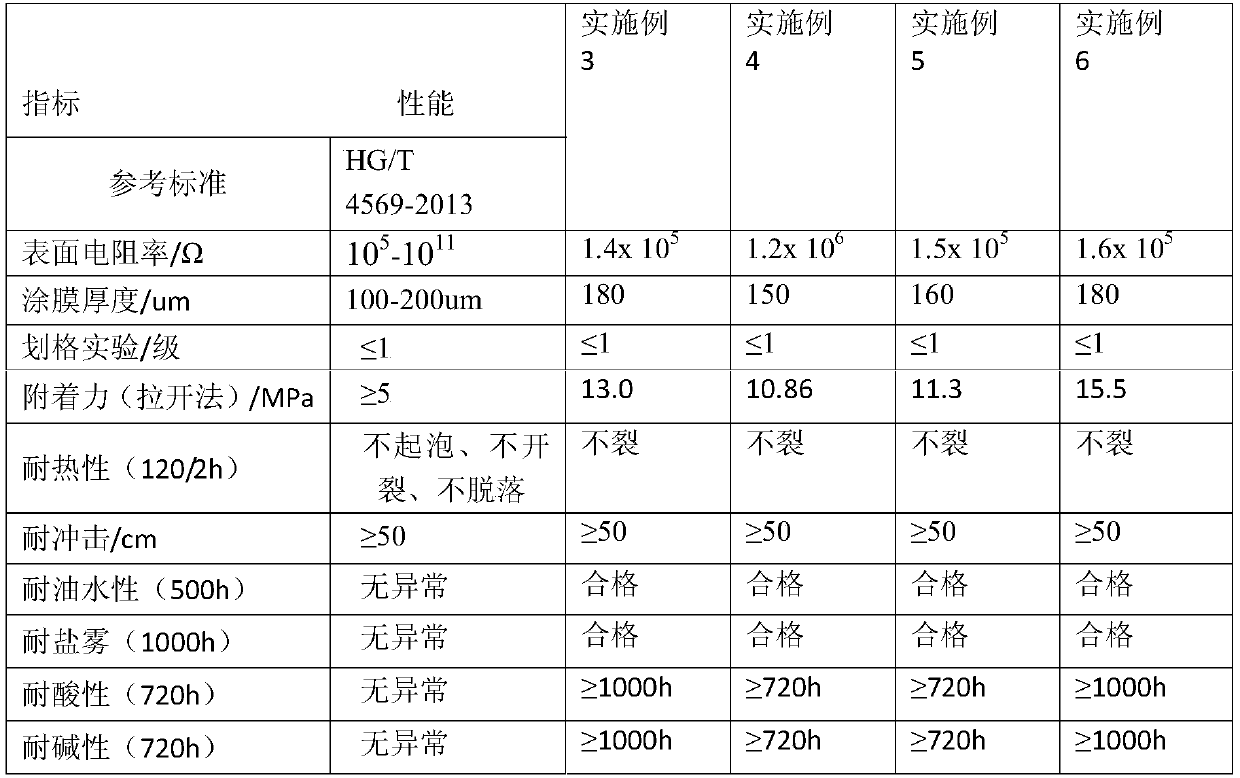

Embodiment 1

[0043] The preparation of graphene‐flaky conductive mica oil tank inner wall conductive static anticorrosion coating: 0.5 parts of the above-mentioned modified graphene (acidified), 10 parts of TDI trimer, 20.5 parts of conductive mica, 3 parts of cyclohexanone, xylene 7 parts, 2 parts of n-butanol, 55 parts of epoxy resin, stirred and mixed evenly at room temperature to obtain a light gray paint solution with a solid content of 55.8% (120°C / 1g / 2h) and a viscosity of 120.3s (coated with 4 cups, 25 ℃), the oil tank conductive coating is obtained by making boards according to the process. The tested properties are shown in Table 1.

Embodiment 2

[0045] The acidified modified graphene is selected. According to the method of Example 1, the paint is adjusted, and the ratio of additives such as modified graphene is controlled, 1 part of modified graphene (acidified), 10 parts of TDI trimer, 19 parts of conductive mica, 3 parts of cyclohexanone, xylene 7 parts, 2 parts of n-butanol, 55 parts of epoxy resin, stir and mix at room temperature to obtain a light gray paint solution with a solid content of 57.5% (120°C / 1g / 2h) and a viscosity of 125.9s (4 cups, 25 ℃), the oil tank conductive coating is obtained by making boards according to the process. The tested properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com