Method for coating and modifying lithium ion battery positive electrode material

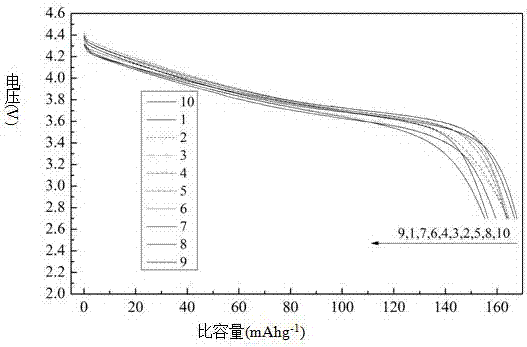

A lithium-ion battery, cathode material technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of coating particle agglomeration, uneven coating, uneven coating, etc., to achieve small volume change, stable structure, The effect of high commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

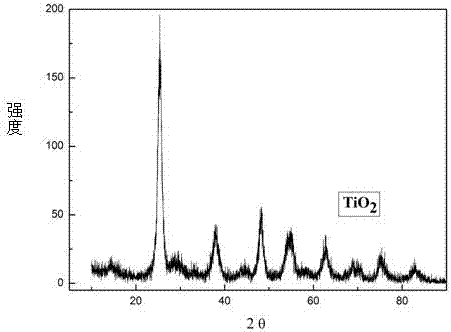

[0021] The method for encapsulating and modifying the cathode material of a lithium ion battery described in this embodiment specifically includes the following steps:

[0022] (1) At room temperature, make a mixed solution of butyl titanate, terephthalic acid, methanol and dimethylformamide according to the molar ratio of 1:2:15:60; then the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Pour into the above mixed solution, and accompanied by mechanical stirring and ultrasonic vibration for a long enough time, so that the medicine and the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Mix evenly, where the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 The molar ratio to butyl titanate is 100:0.5.

[0023] (2) Transfer the homogeneously mixed solution in (1) to a polytetrafluoroethylene-lined autoclave whose temperature has risen to 120 ° C, and keep it for 12 hours to react to obtain the initial positive electrode material LiNi 0.5 co 0.2 m...

Embodiment 2

[0028] (1) At room temperature, make a mixed solution of n-butyl titanate, formic acid, diaminoterephthalic acid and dimethylformamide according to the molar ratio of 1:1.5:20:60; then the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Pour into the above mixed solution, and accompanied by mechanical stirring and ultrasonic vibration for a long enough time, so that the medicine and the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Mix evenly, where the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 The molar ratio to n-butyl titanate is 100:1.

[0029] (2) Transfer the homogeneously mixed solution in (1) to a polytetrafluoroethylene-lined autoclave whose temperature has risen to 120°C, and keep it for 24 hours to obtain the initial positive electrode material LiNi 0.5 co 0.2mn 0.3 o 2 and MOFs (MIL-125-NH 2 @Ti) mixture.

[0030] (3) Suction filter the turbid liquid obtained from the reaction in (2), then vacuum-dry the obtained filter c...

Embodiment 3

[0034] (1) At room temperature, make a mixed solution of titanium tetraisopropoxide, P123, terephthalic acid and dimethylformamide according to the molar ratio of 1:1.5:25:60; then the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Pour into the above mixed solution, and accompanied by mechanical stirring and ultrasonic vibration for a long enough time, so that the medicine and the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 Mix evenly, where the positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 The molar ratio to isopropyl titanate is 100:1.

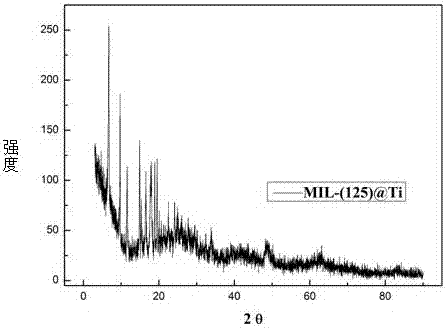

[0035] (2) Transfer the homogeneously mixed solution in (1) to a polytetrafluoroethylene-lined autoclave whose temperature has risen to 120°C, and keep it for 36 hours to obtain the initial positive electrode material LiNi 0.5 co 0.2 mn 0.3 o 2 and a mixture of MOFs (MIL-125@Ti).

[0036] (3) Suction filter the turbid liquid obtained from the reaction in (2), then vacuum-dry the obtained filter cake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com