Medium-high speed trunk-piston diesel and engine oil

A technology of cylindrical piston and diesel engine oil, which is applied in the field of lubricating oil to achieve the effect of extending the maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

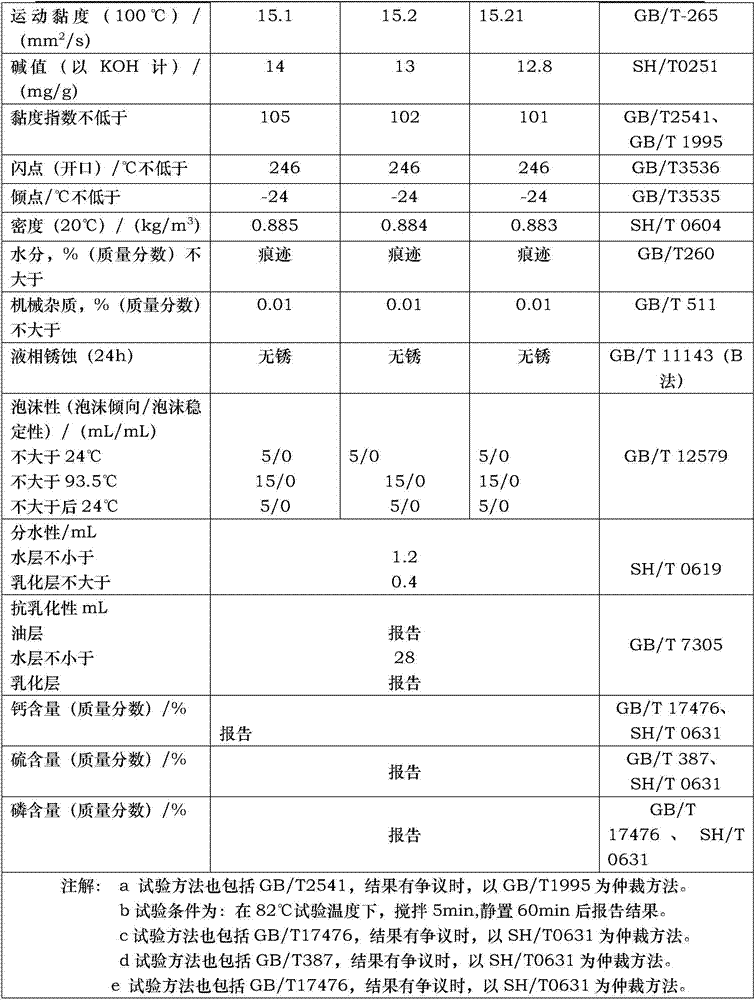

Embodiment 1

[0039] Add 843.5 kg of 500N base oil and 50 kg of 150BS base oil into the blending kettle and raise the temperature to 55°C. 20 kilograms of T155A polyisobutenyl succinimide, 15 kilograms of T115B high-alkaline sulfurized alkylphenate calcium detergent, 0.5 kilogram of nitrogen-containing borate, 25 kilograms of T106D long-chain linear alkylbenzene high-alkaline synthetic sulfonate Calcium acid detergent, 5 kg of T161A high molecular weight polyisobutenyl succinimide dispersant, 13 kg of T203 phosphobisoctyl alkyl zinc salt antioxidant and anticorrosion agent, 3 kg of phenolic ester type antioxidant, 2 kg Dinonyl diphenylamine antioxidant, 2 kg of T602 polymethacrylate pour point depressant, 3 kg of T462 friction modifier dialkyl molybdenum dithiophosphate, 18 kg of T614 viscosity index improver were added and mixed, and the temperature was maintained at Stir at 50-55°C for 10 minutes, finally add 15 grams of T901 methyl silicone oil anti-foaming agent, keep stirring to normal...

Embodiment 2

[0041] Put 848 kg of 500N base oil and 50 kg of 150BS base oil into the blending kettle, raise the temperature to 55°C, add 10 kg of T155A polyisobutenyl succinimide, 20 kg of T115B high alkali value sulfurized alkylphenate calcium detergent, 5 Kilograms of nitrogen-containing borate, 20 kilograms of T106D long-chain linear alkylbenzene high alkali value synthetic calcium sulfonate, 5 kilograms of T161A high molecular weight polyisobutenyl succinimide dispersant, 13 kilograms of T203 phosphobisoctane Zinc salt antioxidant anti-corrosion agent, 2 kg phenol ester type antioxidant antioxidant, 3 kg dinonyl diphenylamine antioxidant, 2 kg T602 polymethacrylate pour point depressant, 4 kg T462 friction modifier Dialkyl molybdenum dithiophosphate and 18 kg of T614 viscosity index improver were added and mixed, the temperature was kept at 50-55 ° C, stirred for 10 minutes, and finally 15 grams of T901 methyl silicone oil antifoaming agent was added, stirred continuously to room temper...

Embodiment 3

[0043] Put 851.5 kg of 500N base oil and 50 kg of 150BS base oil into the blending kettle, raise the temperature to 55°C, add 15 kg of T155A polyisobutenyl succinimide, 10 kg of T115B high alkali value sulfurized alkylphenate calcium detergent, 5 Kilograms of nitrogen-containing borate, 25 kilograms of T106D long-chain linear alkylbenzene high alkali value synthetic calcium sulfonate, 5 kilograms of T161A high molecular weight polyisobutenyl succinimide dispersant, 13 kilograms of T203 phosphobisoctane Zinc salt antioxidant anticorrosion agent, 2 kg phenol ester type antioxidant, 3 kg dinonyl diphenylamine antioxidant, 2 kg T602 polymethacrylate pour point depressant, 3.5 kg T462 friction modifier dialkyl Oxymolybdenum dithiophosphate and 15 kg of T614 viscosity index improver were added and mixed, the temperature was kept at 50-55 ° C, stirred for 10 minutes, and finally 15 grams of T901 methyl silicone oil antifoaming agent was added, stirred continuously to room temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com