Heat insulating strip for aluminum alloy doors and windows, and production method thereof

A technology of aluminum alloy doors and windows and heat insulation strips, which is applied in the field of engineering plastics production, can solve the problems of poor thermal insulation, poor thermal stability, and low tensile strength, and achieve flexibility and fire resistance, good thermal stability, and flame retardancy Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

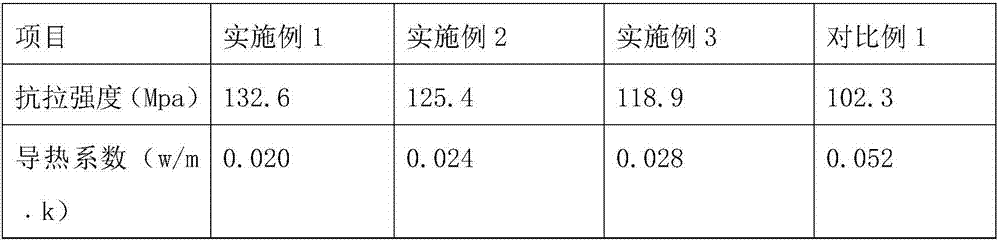

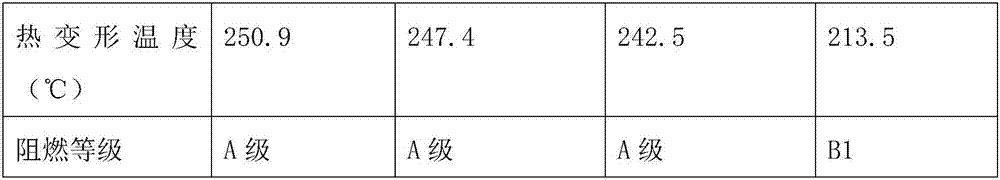

Examples

Embodiment 1

[0041] A heat insulation strip for aluminum alloy doors and windows, comprising the following raw materials in parts by weight: 90 parts of nylon resin, 40 parts of neoprene rubber, 30 parts of polyvinyl chloride resin, 34 parts of phenolic resin, glass 25 parts of fiber, 20 parts of ceramic fiber, 17 parts of fly ash, 27 parts of asbestos powder, 21 parts of floating beads, 26 parts of airgel, 19 parts of graphite powder, 21 parts of lignin, 0.7 parts of toughening agent, coupling agent 0.5 parts, 0.5 parts of antioxidant, 0.5 parts of light stabilizer, 0.5 parts of heat stabilizer and 7 parts of color masterbatch.

[0042] Neoprene rubber is added to the raw material, and neoprene rubber has the advantages of good heat resistance, good flame retardancy and high mechanical strength.

[0043] Polyvinyl chloride resin is added to the raw material, and the polyvinyl chloride resin has the advantages of good flame retardancy, good toughness, high mechanical strength and good elec...

Embodiment 2

[0061] A heat insulating strip for aluminum alloy doors and windows, comprising the following raw materials in parts by weight: 80 parts of nylon resin, 30 parts of neoprene rubber, 20 parts of polyvinyl chloride resin, 22 parts of phenolic resin, 20 parts of glass fiber, and 15 parts of ceramic fiber 13 parts of fly ash, 21 parts of asbestos powder, 19 parts of floating beads, 15 parts of airgel, 17 parts of graphite powder, 15 parts of lignin, 0.6 parts of toughening agent, 0.2 parts of coupling agent, 0.3 parts of antioxidant , 0.4 parts of light stabilizer, 0.3 parts of heat stabilizer and 5 parts of color masterbatch.

[0062] Neoprene rubber is added to the raw material, and neoprene rubber has the advantages of good heat resistance, good flame retardancy and high mechanical strength.

[0063] Polyvinyl chloride resin is added to the raw material, and the polyvinyl chloride resin has the advantages of good flame retardancy, good toughness, high mechanical strength and go...

Embodiment 3

[0081] A heat insulation strip for aluminum alloy doors and windows, comprising the following raw materials in parts by weight: 100 parts of nylon resin, 50 parts of neoprene rubber, 40 parts of polyvinyl chloride resin, 46 parts of phenolic resin, 30 parts of glass fiber, and 25 parts of ceramic fiber 21 parts of fly ash, 33 parts of asbestos powder, 23 parts of floating beads, 37 parts of airgel, 21 parts of graphite powder, 27 parts of lignin, 0.8 parts of toughening agent, 0.8 parts of coupling agent, 0.7 parts of antioxidant , 0.6 parts of light stabilizer, 0.7 parts of heat stabilizer and 9 parts of color masterbatch.

[0082] Neoprene rubber is added to the raw material, and neoprene rubber has the advantages of good heat resistance, good flame retardancy and high mechanical strength.

[0083] Polyvinyl chloride resin is added to the raw material, and the polyvinyl chloride resin has the advantages of good flame retardancy, good toughness, high mechanical strength and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com