Battery packaging material, flexibly packaged battery and battery heat control device

A soft-pack battery and battery technology, which is applied to battery box/case materials, secondary batteries, battery pack components, etc., can solve the problems of insufficient cooling water resistance and corrosion resistance, and is easy to be corroded and perforated, so as to achieve long-term cooling resistance Good liquid corrosion performance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

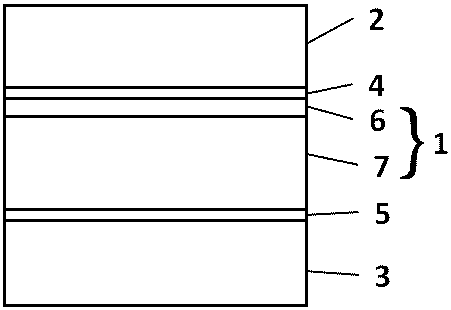

[0100] as attached figure 1 An aluminum-plastic film is provided, which includes an aluminum foil layer 1 and plastic layers 2 and 3 compounded on both sides of the aluminum foil layer, wherein the aluminum foil layer 1 is composed of a 3-series aluminum alloy aluminum foil layer 7 (core material) and 7 It is formed by compounding the aluminum alloy aluminum foil layer 6 (leather material). For example, 3003 aluminum alloy and 7072 aluminum alloy are used for compounding, and the 7072 aluminum alloy layer 6 is compounded on the outside of the 3003 aluminum alloy layer 7 . In other words, the aluminum-plastic film is formed by sequentially stacking a heat-sealing layer, a 3003 aluminum foil layer, a 7072 aluminum foil layer and a nylon layer, wherein the aluminum foil layer and the plastic layer are bonded with a traditional adhesive. In other words, the layers of the aluminum-plastic film from the inside to the outside are: heat-sealing layer, adhesive layer, 3003 aluminum fo...

Embodiment 2

[0105] The structure of this embodiment is roughly similar to that of Embodiment 1. The aluminum alloy layer 1 is also formed by a composite of a core material 7 and a skin material 6, and the skin material 6 is an anode protection layer. The difference is that the 7072 aluminum alloy is replaced by the 3003 aluminum alloy with Zn added (3003+1%Zn or 3003+1.5%Zn in the table below) as the sacrificial anode layer. The potential of 3003+1%Zn is about -0.83V to -0.89V, which is lower than that of 3003 core material.

[0106] Table 1 Alloy chemical composition

[0107]

Embodiment 3

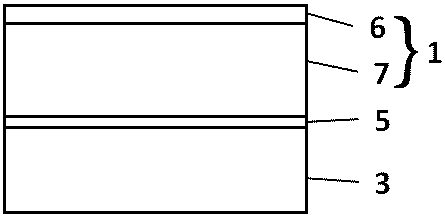

[0109] as attached figure 2 A second aluminum-plastic film is provided, which includes an aluminum foil layer 1 and a thermoplastic resin film layer 3 composited inside the aluminum foil layer, wherein the aluminum foil layer is a composite layer aluminum foil, and the aluminum foil layer contains a core material and is located outside the core material The corrosion potential of the skin material of the aluminum foil layer is lower than that of the core material. Further, the core material of the aluminum foil layer is formed of corrosion-resistant aluminum alloy or pure aluminum. For example, the composite aluminum foil layer 1 is formed by compounding the 3-series aluminum foil layer 7 (such as 3003) and the 7-series aluminum foil layer 6 (such as 7072). Only the inner side of the aluminum foil layer 1 is compounded with a thermoplastic resin film layer 3 (also called a heat-sealing layer 3, such as CPP), without an external nylon protective layer.

[0110] The thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com