A method for manufacturing large-scale ingots through electromagnetic regulation and self-inoculation treatment

A self-inoculation and ingot casting technology, which is applied in the direction of manufacturing tools, casting equipment, casting melt containers, etc., can solve the problem of reducing interface heat transfer, cracks, chiller distribution uniformity, cold core and ingot interface structure uniformity and Stress problems are difficult to control and other problems, and the effects of uniform temperature field distribution, increased nucleation particles, and simple device structure are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

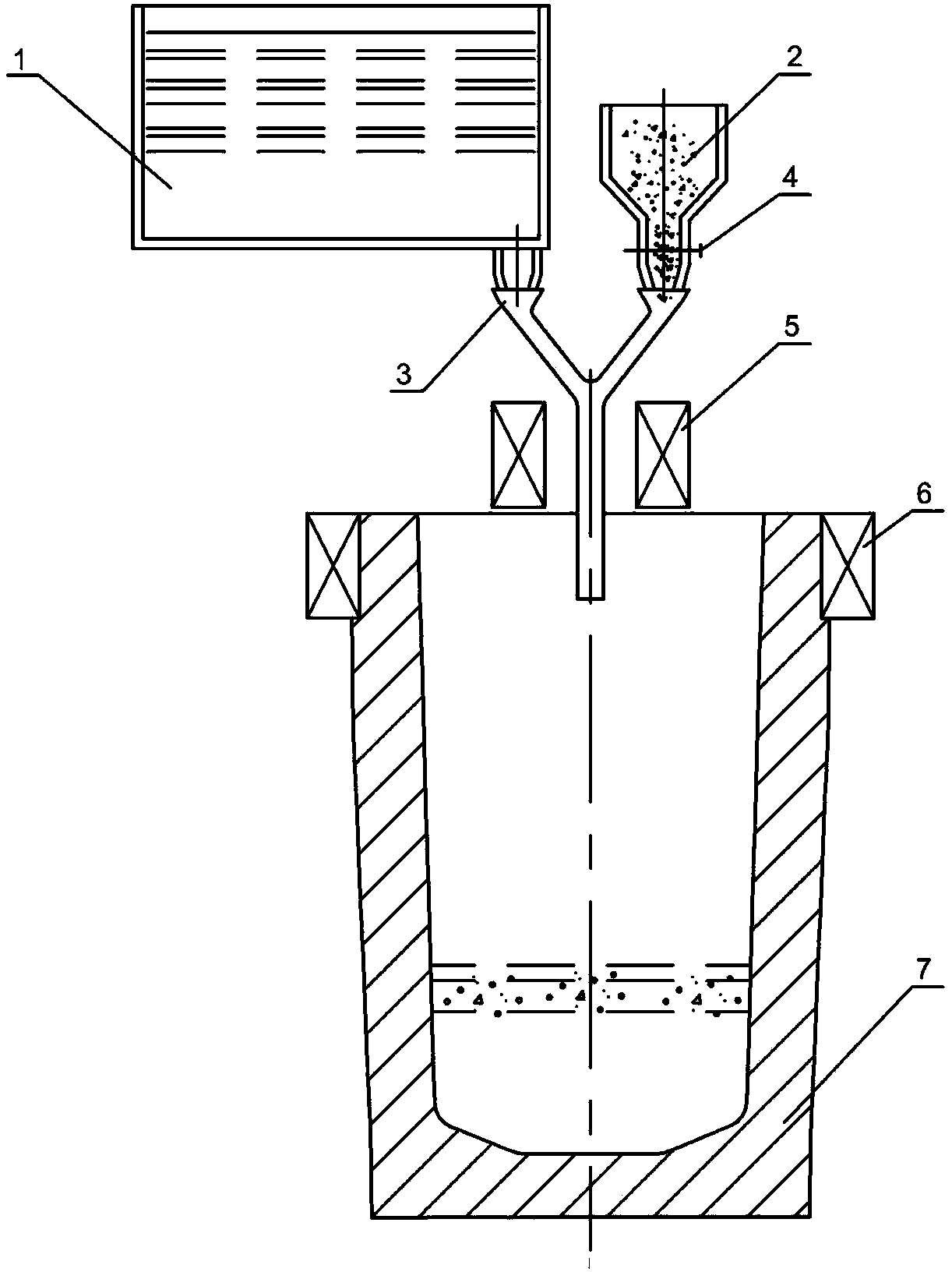

[0041] Such as figure 1 As shown, the ingot mold in this embodiment is a nodular cast iron ingot mold, and the ingot mold is preheated at 300°C before casting and kept for 12 hours; the two-phase feeding nozzle is preheated to 1550°C.

[0042] The casting steel type is Q345B steel, the design ingot weight is 50kg, the melting temperature is 1620°C, the casting temperature is 1580°C, the estimated casting time is 2min, the casting process is protected by argon, and the molten slag is sprinkled on the liquid surface after pouring.

[0043] In order to ensure the action time and effect of the electromagnetic field and the inoculant, two electromagnetic fields are used, that is, the electromagnetic device I5 applied to the straight section of the two-phase feeding nozzle and the electromagnetic device II6 applied to the riser of the ingot mold.

[0044] The structural parameters of the inoculant are provided by numerical simulation and thermodynamic calculation results. The inocul...

Embodiment 2

[0048] Such as figure 1 As shown, the ingot mold in this embodiment is graphite ingot mold, and the ingot mold is preheated at 200°C before casting, and kept for 12 hours; the two-phase feeding nozzle is preheated to 685°C.

[0049] The casting metal is aluminum-silicon alloy, the design ingot weight is 20kg, the melting temperature is 800°C, the casting temperature is 750°C, and the casting process is protected by argon.

[0050] The inoculant is made of aluminum-silicon alloy small pieces. In order to prevent foreign impurities from being brought in, the inoculant is cleaned first and then dried in a vacuum oven at 100°C for 24 hours for later use.

[0051] When casting, the aluminum-silicon alloy liquid in the ladle is poured into the ingot mold through the two-phase feeding nozzle. When the aluminum-silicon alloy liquid is poured to 1 / 2 of the inner cavity height of the ingot mold, the feeding control valve is opened and stored in the incubator. The aluminum-silicon alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com