A kind of zirconium phosphate lubricating grease with n, N`-dimethylpiperazine supported by interlayer and its preparation method

A technology of zirconium phosphate grease and dimethylpiperazine, which is applied in the field of grease and its preparation, can solve the problems of uneven particle size distribution, high preparation cost, influence on use, etc., and achieves good compounding effect and uniform particle size. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

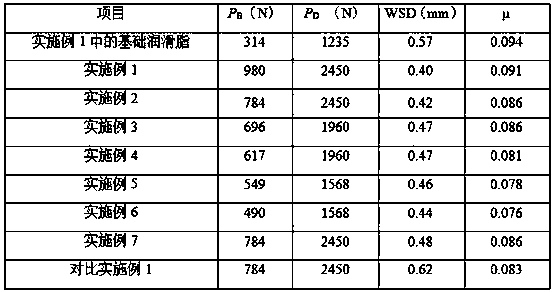

Examples

Embodiment 1

[0025] [C 6 h 16 N 2 ] 0.5 Zr(H 0.5 PO 4 ) 2 h 2 The preparation method of the O material: according to the molar ratio, zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 0, Sinopharm Chemical Reagent Co., Ltd.): water (H 2 O): phosphoric acid (H 3 PO 4 , Aladdin Reagent (Shanghai) Co., Ltd.): hydrofluoric acid (HF, Sinopharm Chemical Reagent Co., Ltd.): N, N'-dimethylpiperazine (C 6 h 14 N 2 , TCI (Shanghai) Chemical Industry Development Co., Ltd.) = 1.0: 83: 2.0: 4.0: 3.0 Feed preparation. Add 0.0067 mmol (2.161 g) zirconium oxychloride octahydrate, 0.5556 mol (10 mL) water, 0.0133 mol (1.531 g) phosphoric acid, and 0.0271 mol (1.360 g) hydrofluoric acid to the 25 ml polytetrafluoroethylene liner Acid, 0.0199 mol (2.316 g) N, N'-dimethylpiperazine; finally stir the mixture fully with a stirring rod, then put the liner into the reaction kettle and tighten it, put it in an oven at 180°C, in the oven After reacting for 72 hours, take it out, wash the sample, and a...

Embodiment 2

[0029] [C 6 h 16 N 2 ] 0.5 Zr(H 0.5 PO 4 ) 2 h 2 The preparation method of the O material is the same as in Example 2, the difference is that the molar ratio of the feed is adjusted to zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 0, Sinopharm Chemical Reagent Co., Ltd.): water (H 2 O): phosphoric acid (H 3 PO 4 , Aladdin Reagent (Shanghai) Co., Ltd.): hydrofluoric acid (HF, Sinopharm Chemical Reagent Co., Ltd.): N, N'-dimethylpiperazine (C 6 h 14 N 2 , TCI (Shanghai) Chemical Industry Development Co., Ltd.) = 1.0 : 83 : 2.0 : 3.0 : 3.0, adjust 0.0271mol (1.360 g) hydrofluoric acid to 0.0203 mol (1.020 g), use X-ray powder diffraction ( XRD) for crystal structure characterization, to obtain products with small particle sizes ranging from 0.1µm to 0.5µm.

[0030] The preparation method of lithium-based grease: weigh 90.0 g of base oil polyalphaolefin, first pour 50.0 g of base lubricating oil into the grease-making kettle, start the stirrer, heat up to 75 ± 5 ℃...

Embodiment 3

[0033] [C 6 h 16 N 2 ] 0.5 Zr(H 0.5 PO 4 ) 2 h 2 The preparation method of the O material is the same as in Example 2, the difference is that the molar ratio of the feed is adjusted to zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 0, Sinopharm Chemical Reagent Co., Ltd.): water (H 2 O): phosphoric acid (H 3 PO 4 , Aladdin Reagent (Shanghai) Co., Ltd.): hydrofluoric acid (HF, Sinopharm Chemical Reagent Co., Ltd.): N, N'-dimethylpiperazine (C 6 h 14 N 2 , TCI (Shanghai) Chemical Industry Development Co., Ltd.) = 1.0 : 70 : 2.0 : 3.0 : 3.0, adjust 0.5556mol (10 mL) water to 0.4686 mol (8.43 ml), use X-ray powder diffraction (XRD) Characterize the crystal structure to obtain products with small particle sizes ranging from 0.1µm to 0.5µm.

[0034] The preparation method of lithium-based grease: weigh 90.0 g of base oil polyalphaolefin, first pour 50.0 g of base lubricating oil into the grease-making kettle, start the stirrer, heat up to 75 ± 5 °C, and put in 15.4 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com