Preparation method of nanoscale laser array

A laser array, nano-scale technology, used in lasers, laser devices, laser parts, etc., to achieve the effects of strong controllability, good thermal stability, high light absorption and emission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

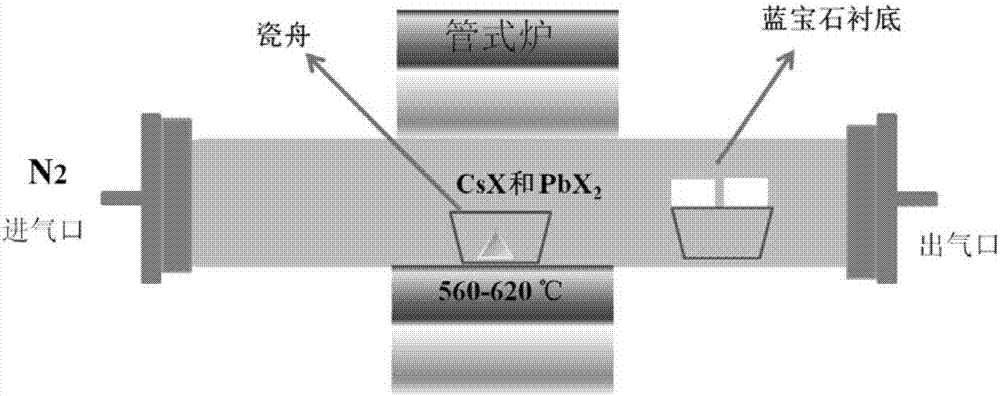

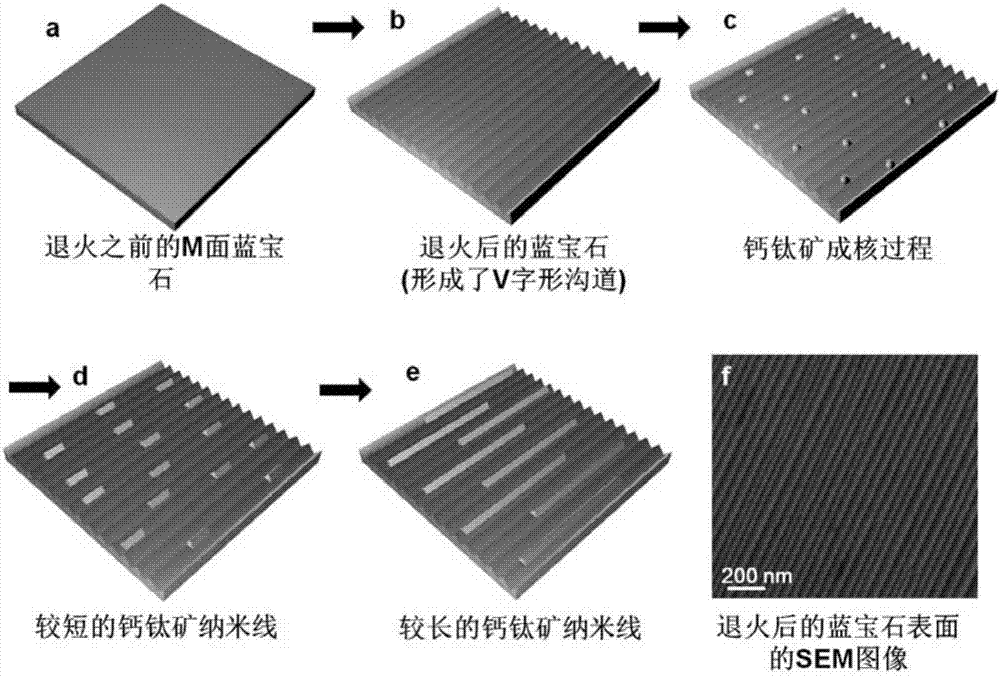

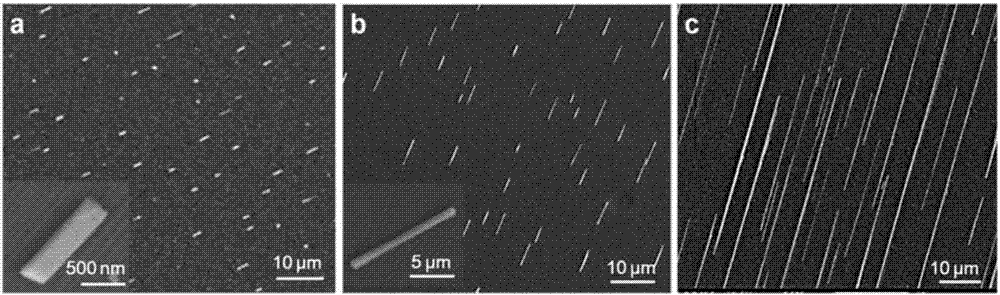

[0039] Example 1, such as Figures 1 to 7 As shown, the preparation of in-plane aligned CsPbBr 3 nanoscale laser array method, the M-Plane sapphire (as attached figure 2 Shown in a) Annealed at 1400°C for 10 hours, then ultrasonically cleaned with acetone, isopropanol, and deionized water for 10 minutes, and finally dried in a nitrogen atmosphere to form a "V"-shaped channel on the surface. as attached figure 2 (b) shown.

[0040] CsBr and PbBr 2 The powder is mixed according to 1:1 and placed in the No. 1 porcelain boat, and then the porcelain boat is placed in the middle temperature zone of the tube furnace, and the annealed M-face sapphire is placed in the No. 2 porcelain boat and placed downstream low temperature zone. as attached figure 1 As shown, vacuumize and feed high-purity nitrogen to exhaust the oxygen in the system on the one hand, and on the other hand as a carrier gas to raise the temperature of the tube furnace to 620°C, keep the pressure in the tube fu...

Embodiment 2

[0043] A preparation of CsPbI aligned in-plane 3 methods for nanoscale laser arrays, such as Figures 1 to 7 As shown, the M-Plane Sapphire (as attached figure 2 Shown in a) Annealed at 1400°C for 10 hours, then ultrasonically cleaned with acetone, isopropanol, and deionized water for 10 minutes, and finally dried in a nitrogen atmosphere to form a "V"-shaped channel on the surface. as attached figure 2 (b) shown.

[0044] CsI and PbI 2 The powder is mixed according to 2:1 and placed in the No. 1 porcelain boat, and then the porcelain boat is placed in the middle temperature zone of the tube furnace, and the annealed M-surface sapphire is placed in the No. 2 porcelain boat and placed downstream low temperature zone. as attached figure 1 As shown, vacuumize and feed high-purity nitrogen to exhaust the oxygen in the system on the one hand, and on the other hand as a carrier gas to raise the temperature of the tube furnace to 560 ° C, keep the pressure in the tube furna...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com