A nickel-free superelastic titanium-based shape memory alloy and its preparation method and application

A technology of memory alloy and superelasticity, which is applied in the field of memory alloy materials to achieve the effects of high recoverable strain, low modulus and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

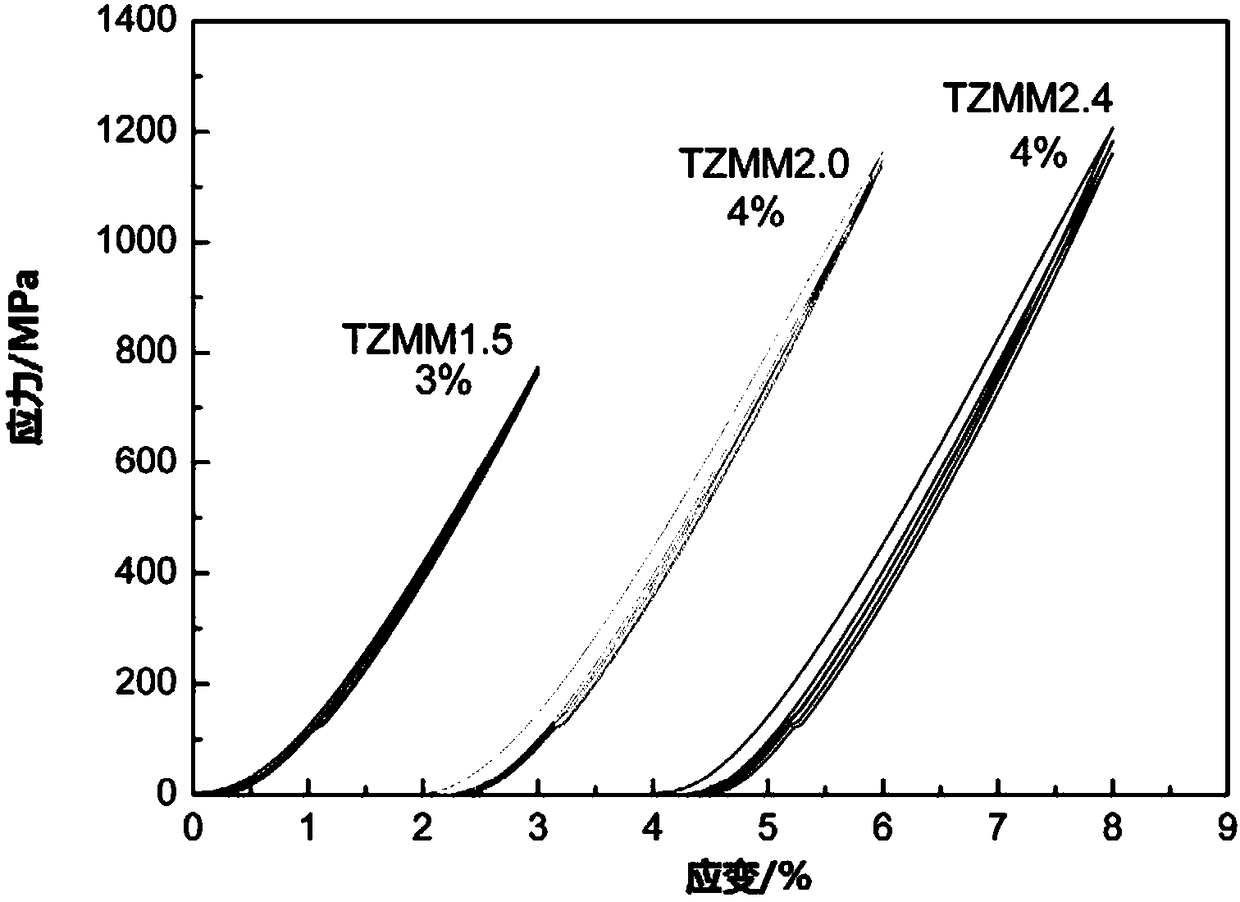

[0043] This embodiment mainly consists of 33.5wt.% titanium, 63wt.% zirconium, 2wt.% molybdenum, and 1.5wt.% manganese. Embodiment 1 main preparation method, comprises the following steps:

[0044](1) Proportioning pure Ti powder, Zr powder, Mo powder, and Mn powder according to the mass percentage of Example 1, using ball milling method (ball mill) to mix the powder evenly, the ball milling time is 6 hours, and the purity of the powder used is all at 99.5wt % or more, the mesh number is 300 mesh. Then the uniformly mixed powder is cold isostatically pressed in the compression medium hydraulic oil, the actual pressure is 172MPa, the temperature is 30-100°C, and the holding time is 5 minutes to obtain a green body.

[0045] (2) Put the green body prepared in step (1) into a vacuum sintering furnace for high-temperature sintering. The sintering condition is heated at 5°C per minute to 1200°C at room temperature, and kept at 1200°C for 5 hours. Cooling, during which the vacuum ...

Embodiment 2

[0056] This embodiment mainly consists of 33wt.% titanium, 63wt.% zirconium, 2wt.% molybdenum, and 2wt.% manganese. Embodiment 2 main preparation method, comprises the following steps:

[0057] (1) Except that the pure Ti powder, Zr powder, Mo powder, and Mn powder are proportioned according to the mass percentage of the embodiment 2, the step (1) of the embodiment 2 is consistent with the step (1) of the implementation 1.

[0058] (2) Step (2) of Example 2 is consistent with Step (2) of Example 1, and the shape memory alloy of Example 2 with low modulus and high strength is prepared.

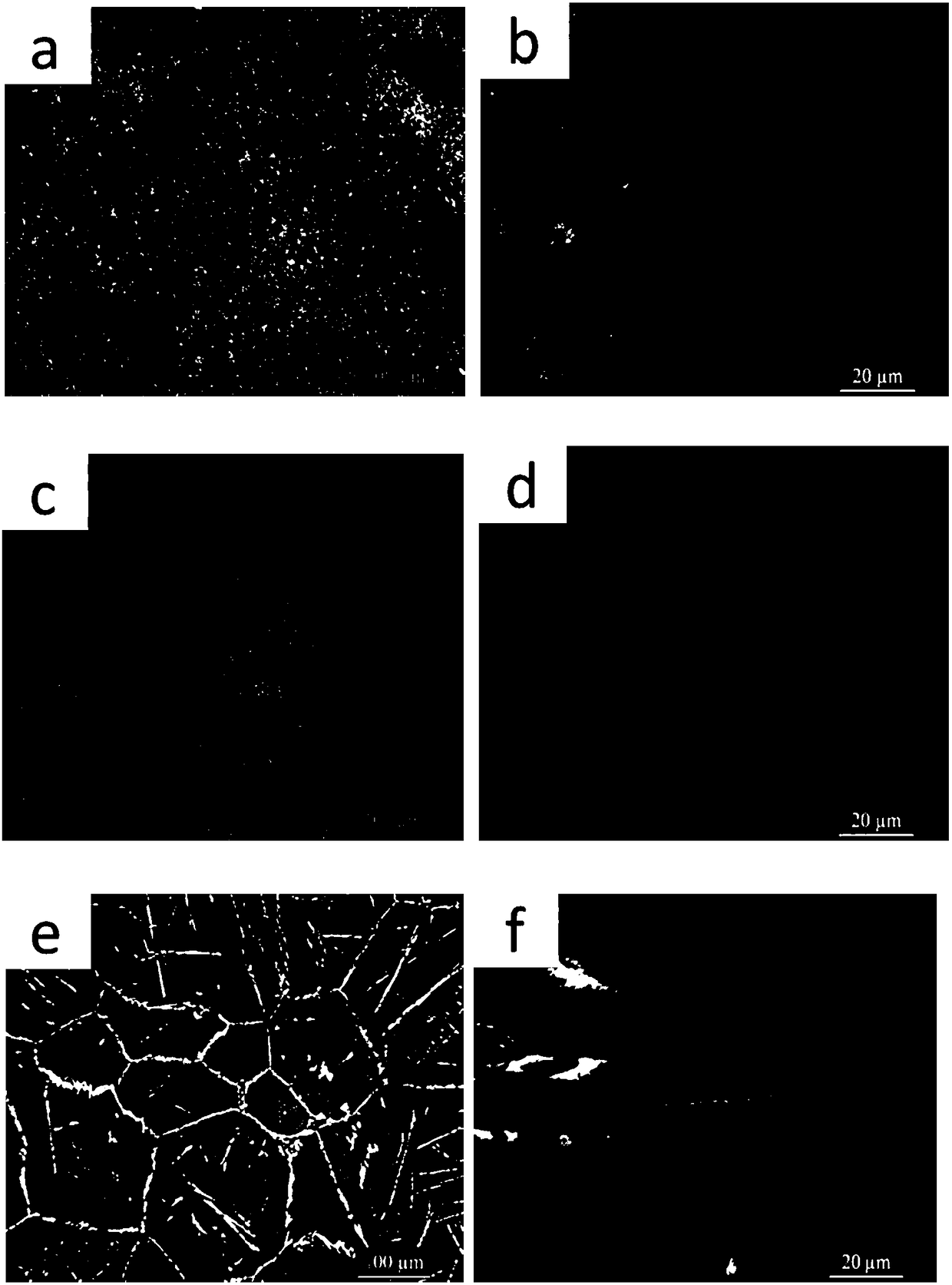

[0059] Carry out porosity measurement (method is the same as embodiment 1) to the shape memory alloy of sintered embodiment 2, the porosityfigure 1 c and 1d, figure 1 The alloy grains shown in c are mostly hexagonal and belong to the β phase of titanium alloy. figure 1 The needle-like precipitates in the grains and grain boundaries shown in d belong to the α"phase.

[0060] The shape-memory ...

Embodiment 3

[0062] This embodiment mainly consists of 32.6wt.% titanium, 63wt.% zirconium, 2wt.% molybdenum, and 2.4wt.% manganese. Embodiment 2 main preparation method, comprises the following steps:

[0063] (1) Except that the pure Ti powder, Zr powder, Mo powder, and Mn powder are proportioned according to the mass percentage of the embodiment 3, the step (1) of the embodiment 3 is consistent with the step (1) of the implementation 1.

[0064] (2) Step (2) of Example 3 is consistent with Step (2) of Example 1, and the shape memory alloy of Example 3 with low modulus and high strength is prepared.

[0065] Carry out porosity measurement (same as embodiment 1) to the memory alloy of sintered embodiment 3, the porosityfigure 1 As shown in e and 1f, figure 1 The alloy grains shown in e are mostly hexagonal and belong to the β phase of titanium alloy. figure 1 The needle-like precipitates in the crystal grains and grain boundaries shown in f belong to the α"phase.

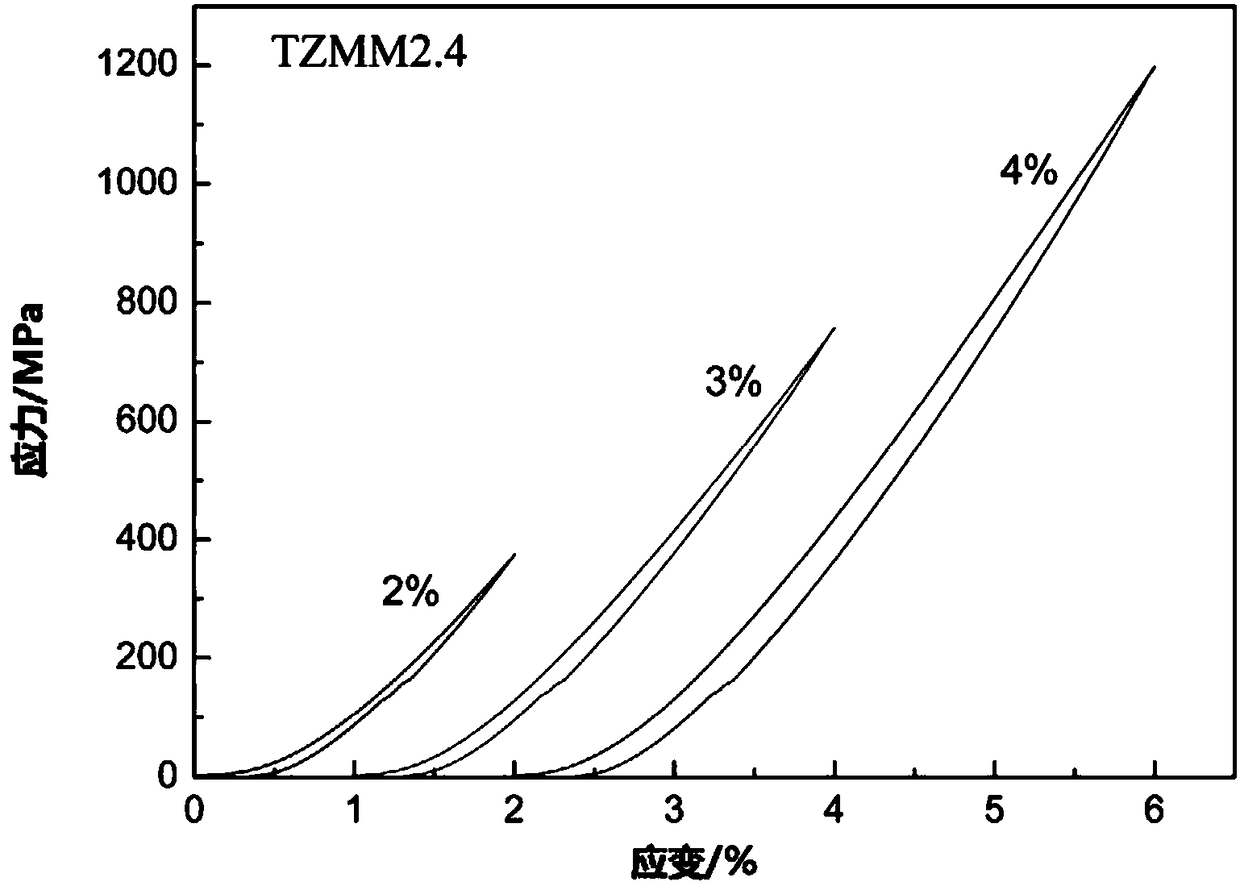

[0066] Carry out roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com